Particular kind differential screw elevation type completely plastic valve

A differential screw and lifting technology, which is applied in the field of special differential screw lifting all-plastic valves, can solve the problems of easy rusting of iron materials, valve corrosion, and affecting the use effect, so as to achieve fast opening and closing operations and realize plastic valves. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

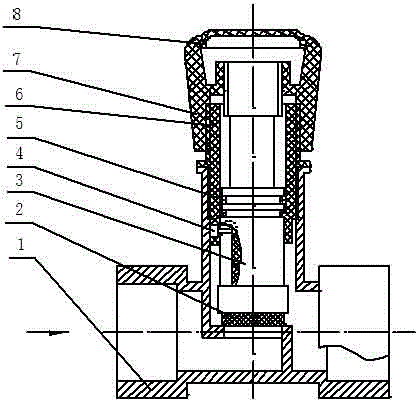

Embodiment 1

[0025] A special differential screw lift type full plastic valve, including: valve body 1, soft gasket 2, valve stem 3, anti-rotation element, O-ring 5, valve cover 6, opening and closing differential nut 7 and cover 8. The valve stem 3 is inserted into the valve body 1, and a soft gasket 2 is provided at the joint between the valve stem 3 and the valve body 1. The upper part of the valve stem 3 is connected with the opening and closing differential nut 7 through a left-handed thread. The valve cover 6 is arranged on the outside of the valve stem 3 and is threaded with the opening and closing differential nut 7 through a right-handed thread. The valve stem 3 cooperates to force the valve stem 3 to keep moving up and down without turning during the opening and closing process of the valve. In this embodiment, the anti-rotation element is a key pin 4 , and the key pin 4 passes through the valve cover 6 and is embedded into the valve stem 3 . An O-shaped gasket 5 is also arrange...

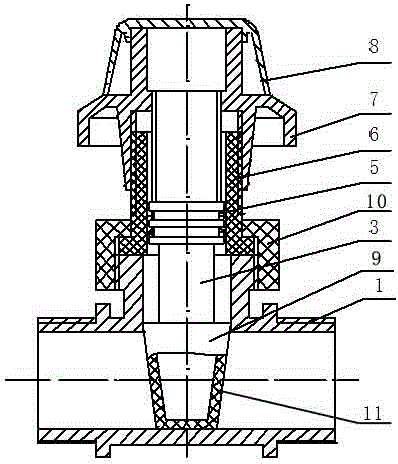

Embodiment 2

[0036] A special differential screw lift type full plastic valve, including: valve body 1, valve stem 3, O-ring 5, valve cover 6, opening and closing differential nut 7, anti-rotation element, cover 8, soft sealing shell 9 and fastening wire ring 10. The anti-rotation element in this example is a wedge gate 11 .

[0037] The bottom of the valve stem 3 is equipped with a wedge gate 11, the wedge gate 11 is covered with a soft sealing shell 9 and inserted into the square cavity of the valve body 1, the square cavity is just in line with the square outer edge of the wedge gate 11 upper end The edge matches. The upper part of the valve stem 3 is threaded with the opening and closing differential nut 7 through a left-handed thread, and the valve cover 6 is arranged on the outside of the valve stem 3 and is threaded with the opening and closing differential nut 7 through a right-handed thread. The valve cover 6 in the shape of a cylindrical member of the flange is screwed to the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com