Anti-coking device and gas delivery pipeline for large gate valve

An anti-coking and gate valve technology, applied in valve devices, valve heating/cooling devices, valve details, etc., can solve the problem of pipeline valves not being able to switch normally, and achieve the effect of flexible action and simple material selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

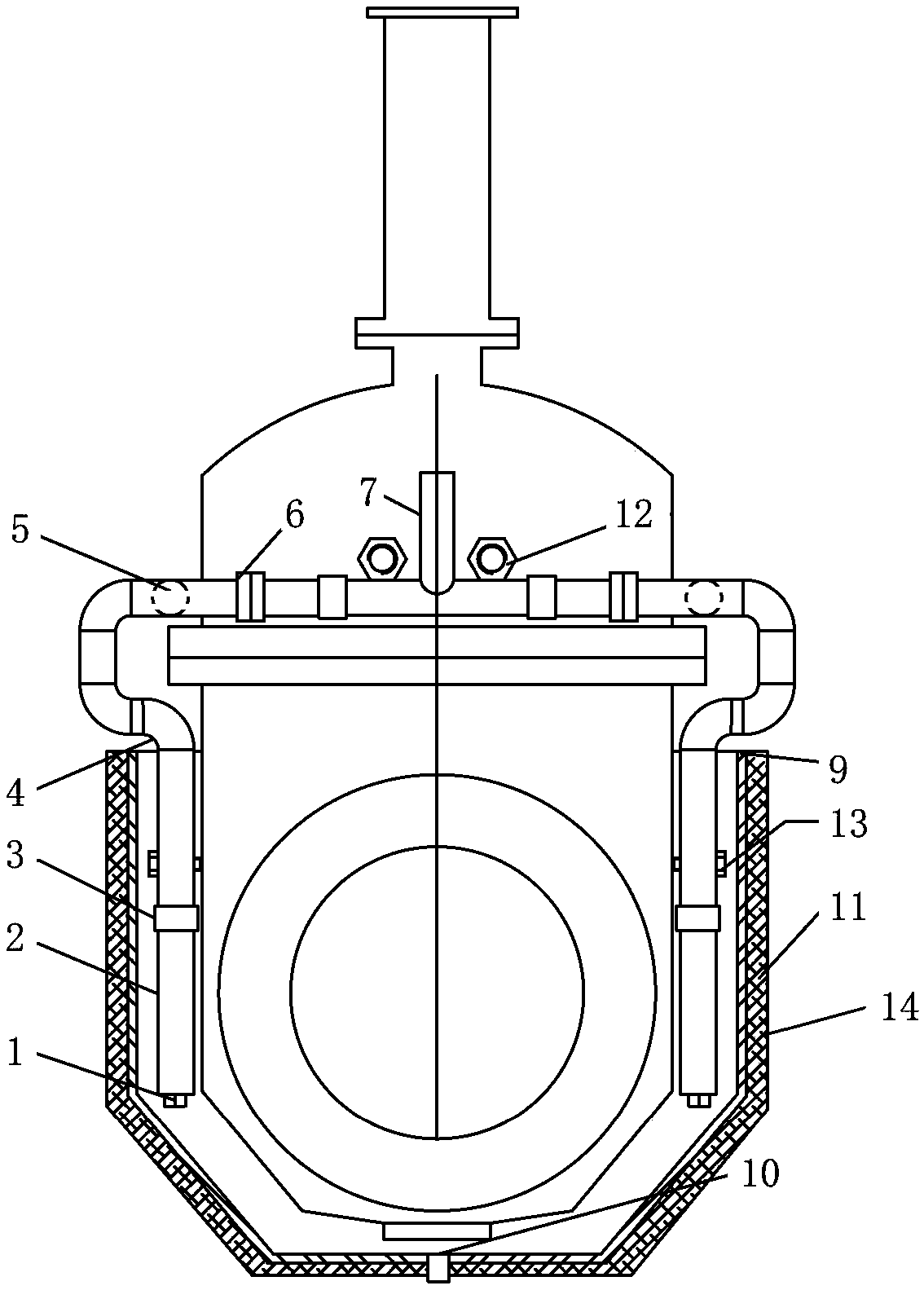

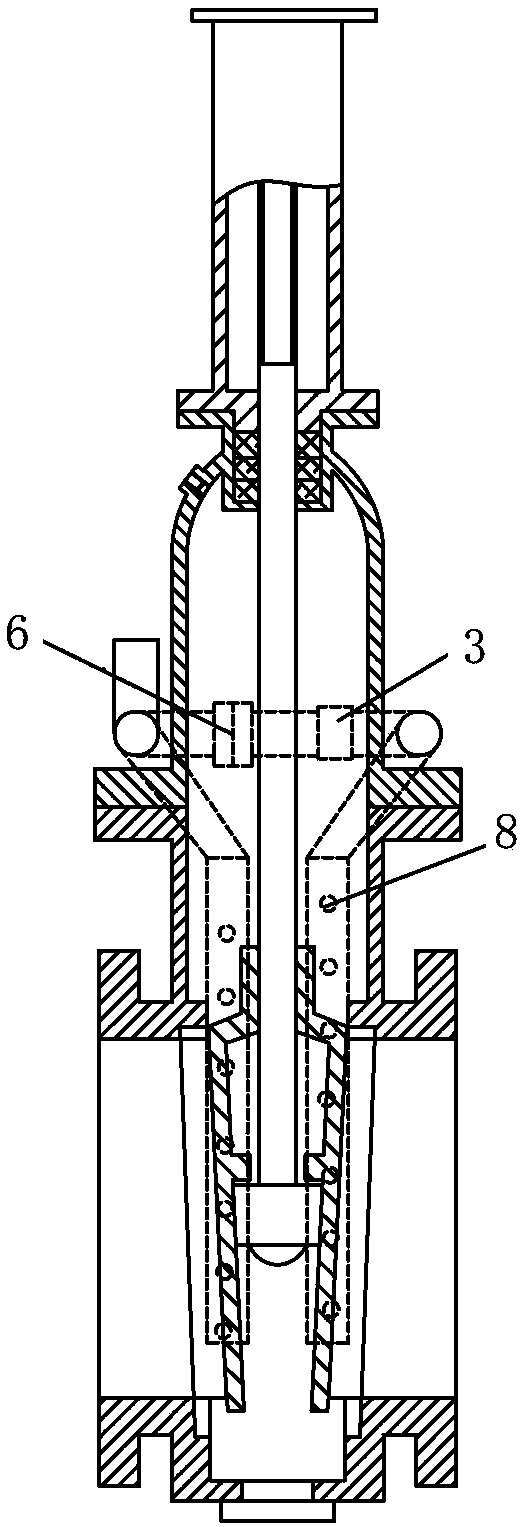

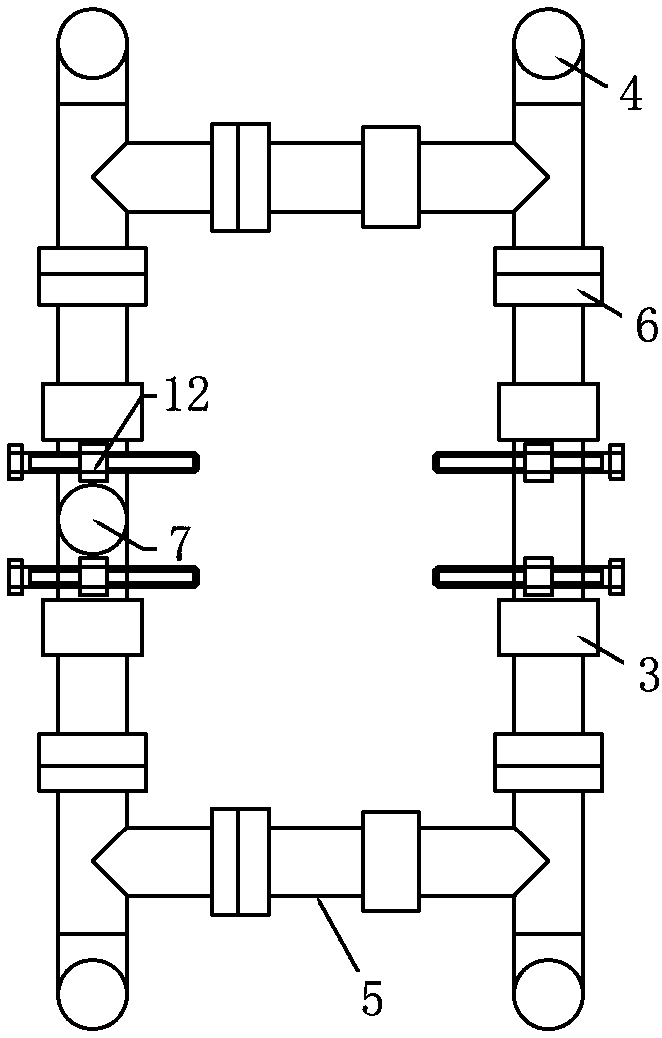

[0027] Hereinafter, the anti-coking device of the gas delivery pipeline and its gate valve according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

[0028] According to the structural form of the gate valve body and the actual situation, the applicant found that the jam caused by tar accumulation in the valve plate and the valve plate running guide groove was the main reason why the valve could not operate. In order to prevent the crystallization and coking of the medium in the valve gas from entering the guide groove of the valve plate and affecting the normal opening of the valve, the present invention provides an anti-coking device for a large gate valve. The heating unit is used to heat the guide grooves on both sides of the gate valve body. The invention uses a simple combined heating device to heat and soften the focal points that are prone to coke, that is, to heat only the valve plate guide g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com