Straightening detection device for cast-iron pipes

A detection device, cast iron pipe technology, applied in measuring devices, instruments, using ultrasonic/sonic/infrasonic waves, etc., can solve the problems of non-dense material structure, affecting production efficiency, and rough pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

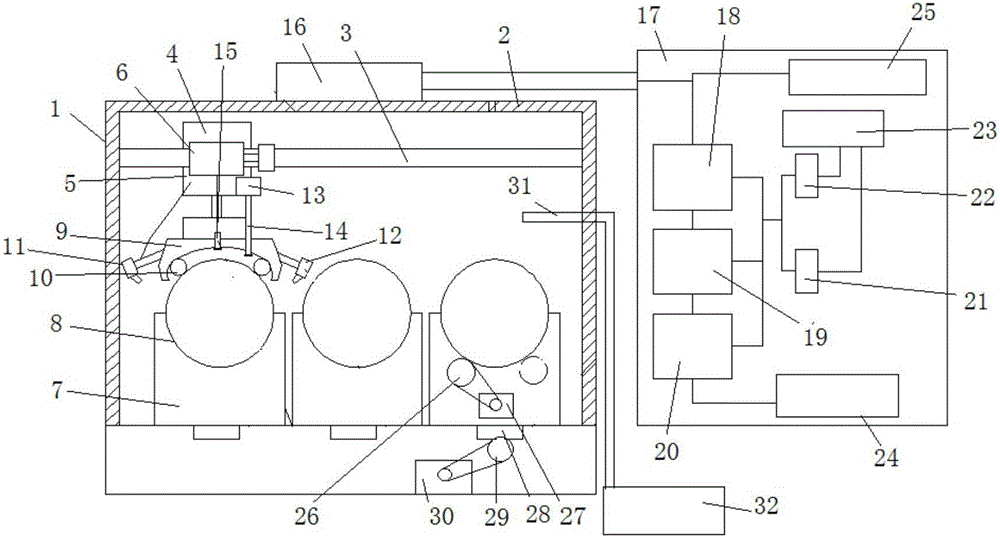

[0009] Referring to the accompanying drawings, a cast iron pipe alignment detection device includes a box body 1, a sound insulation layer 2 is provided on the inner wall of the box body 1, a guide rail 3 is fixedly installed on the inner top of the box body 1, and a guide rail 3 is fixed on the inner wall of the box body 1 A sliding seat 4 is slidably installed, and an adjustable cylinder 5 is installed on the sliding seat 4. A servo motor 6 is installed on the sliding seat 4 to control the left and right movement of the sliding seat 4 to select and detect different pipe fittings. The bottom of the box body 1 is provided with three different support bases 7, the support base 7 is provided with an arc-shaped pipe groove 8, and the bottom of the arc-shaped official groove 8 is provided with left and right two detection rollers 26, so that The detection roller 26 is driven by the transmission device 27 and can drive the pipeline to be detected to rotate. The bottom of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com