Curing barrel surface dose rate detection device and detection method thereof

A technology of detection device and detection method, which is applied to measurement devices, dosimeters, sampling devices, etc., can solve the problems of time-consuming, labor-intensive, and low degree of automation in detection, and achieve the effects of reducing inefficiency, avoiding radiation exposure, and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

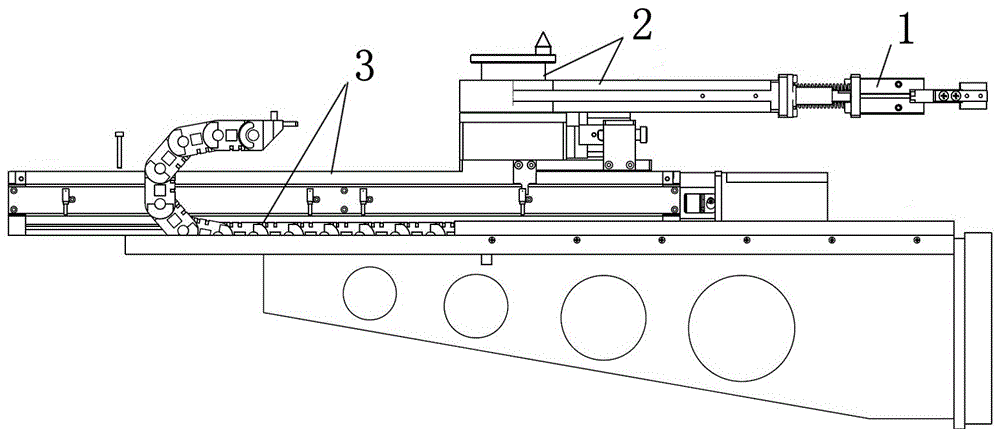

[0038] Curing barrel surface dose rate detection device, such as figure 1 As shown, it includes a wipe sampling device and a dose detection device. The wipe sampling device includes a control system, a flexible chuck 1, a rotating mechanism 2 for rotating the flexible chuck 1, and a linear movement for the linear movement of the flexible chuck 1. The mechanism 3, the flexible chuck 1, the rotating mechanism 2 and the linear moving mechanism 3 are all connected with the control system.

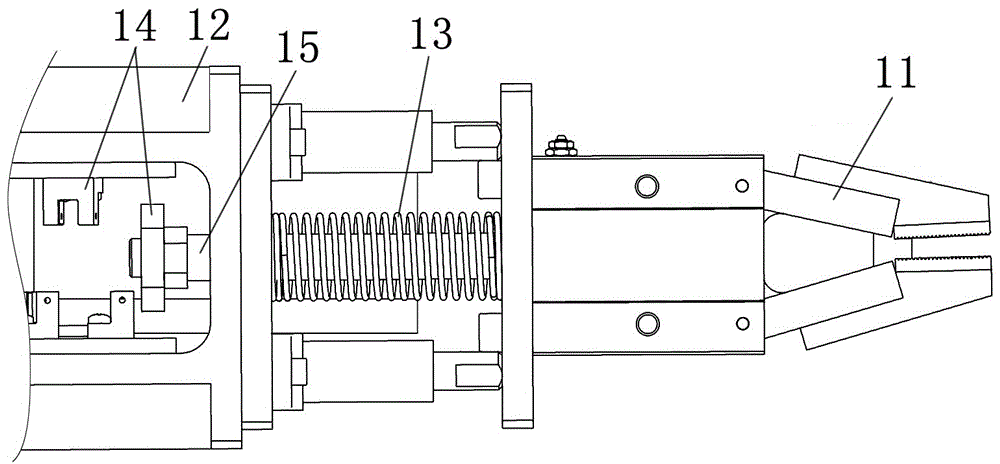

[0039] Among them, the flexible chuck 1 is used to clamp the sampling cloth; in order to ensure the effective contact between the sampling cloth and the curing barrel, and to avoid the influence of the deviation of the barrel rotation on the wiping device, the present invention optimizes the flexible chuck 1, the specific settings are as follows:

[0040] The flexible chuck 1 includes a pneumatic gripper 11 for clamping the sampling cloth, an installation arm 12 for installing the pneumatic gr...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that this embodiment optimizes the structure of the dose detection device, and the specific settings are as follows:

[0057] The dose detection device includes two dose probes connected to the host. The dose probe is arranged in the dose measurement tray tube.

[0058] The dose detection step includes: using a dose probe to monitor the dose data at the position of the curing barrel and at a position 1m around the curing barrel in real time, respectively, and transmitting the detected data to the host computer, which displays the data. At the same time, the data received by the host is also saved in the form of EXCEL. When you need to query, you only need to query by bucket number or date.

[0059] Through the setting of the invention, the detected data can be directly stored in the host computer and printed out in the form of EXCEL, which improves the accuracy of data recording.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com