Virtual grinding wheel simulation method based on randomly distributed multiple abrasive particles

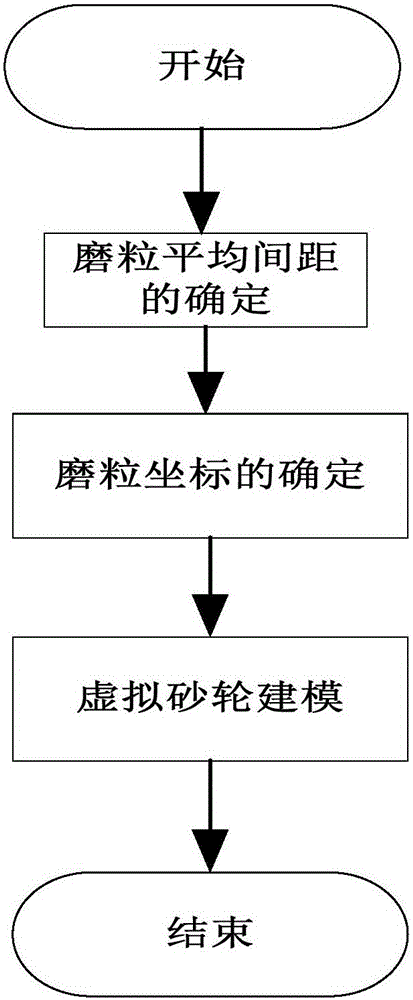

A technology of random distribution and simulation method, used in design optimization/simulation, special data processing applications, instruments, etc., can solve the problem of low simulation analysis accuracy of single abrasive particle grinding, and achieve the effect of improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

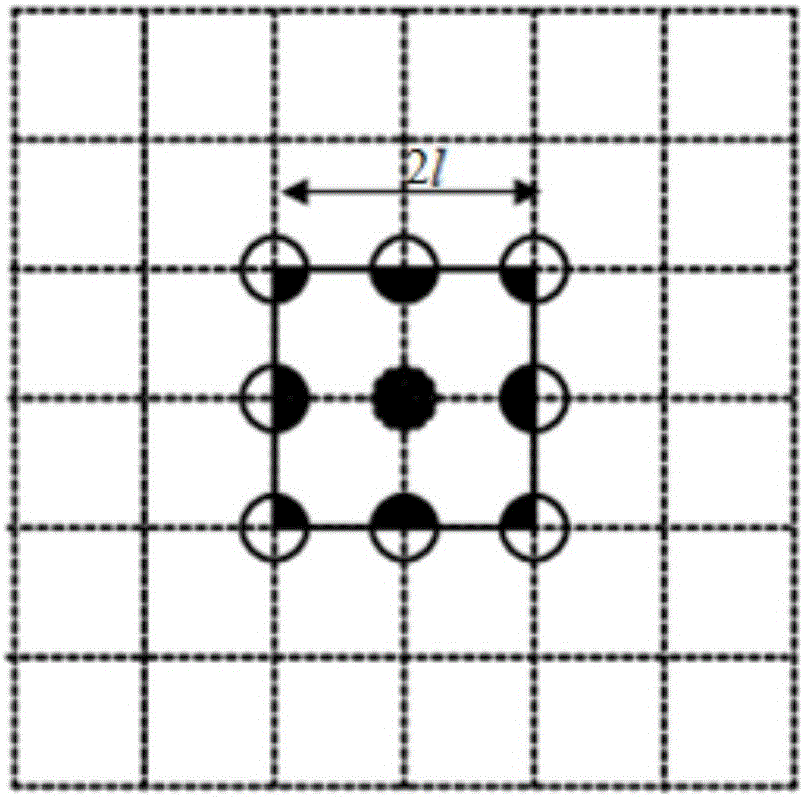

[0022] (1) Determination of the average spacing of abrasive grains: Assume that a number of abrasive grains are evenly distributed in a square with a side length of 2l, such as figure 2 As shown, assuming that each small square vertex has one abrasive grain, the number of abrasive grains equivalently distributed on a square with a side length of 2l is 4. If the grain size of the grinding wheel is 120#, the abrasive grain density can be obtained as 40 / mm -2 , Through calculation, the average spacing l of abrasive grains can be obtained as 0.03mm.

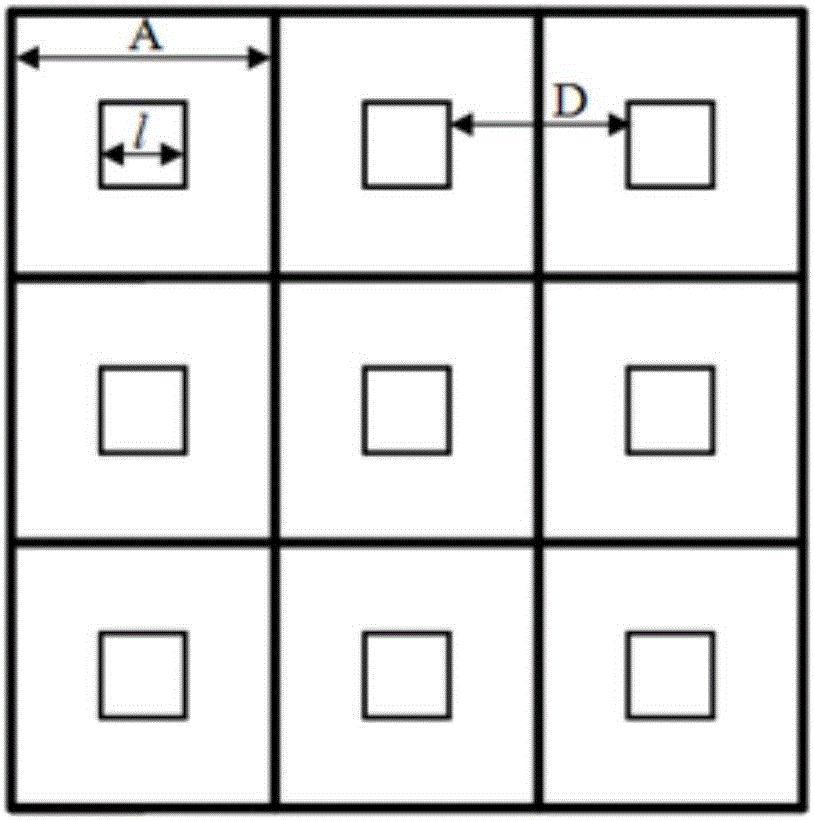

[0023] (2) Determination of abrasive grain coordinates: In the modeling process of multiple abrasive grains, in order not to allow the abrasive grains to overlap each other, a virtual grid method can be used, and one abrasive grain is distributed in each grid. The position in the grid is random. The positions of abrasive grains are randomly distributed in each small square of l×l. The side length of the grid is A=474um, which can...

example 2

[0028] The determination of the average spacing and coordinates of abrasive grains in this example is similar to that in Example 1, and only the process of model establishment is described below.

[0029] (1) Take the area on the surface of the diamond grinding wheel as the prototype of the virtual grinding wheel, wherein the particle size of the diamond grinding wheel abrasive grains is 230#, and the abrasive grain density is 127mm as previously measured -2 , The nominal size is in the range of 50-70μm. When modeling, the side length of the hexahedron is taken as 50 μm. The bonding agent is a resin bonding agent whose shape is simplified as a cuboid. The virtual grinding wheel structure model is established by randomly distributing 4×4×1 virtual abrasive grains in the cuboid bond.

[0030] (2) Generation of position and attitude random numbers. Based on the Rnd random function in the VB programming language, in the virtual grid of 4 × 4 × 1, the random coordinate positions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com