Automatic fresh rice machine

A fresh rice machine, automatic technology, used in instruments, coin-operated equipment for distributing discrete items, grain handling, etc., can solve problems such as inability to confirm freshness, inability to personally watch the packaging process, and eaters eating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

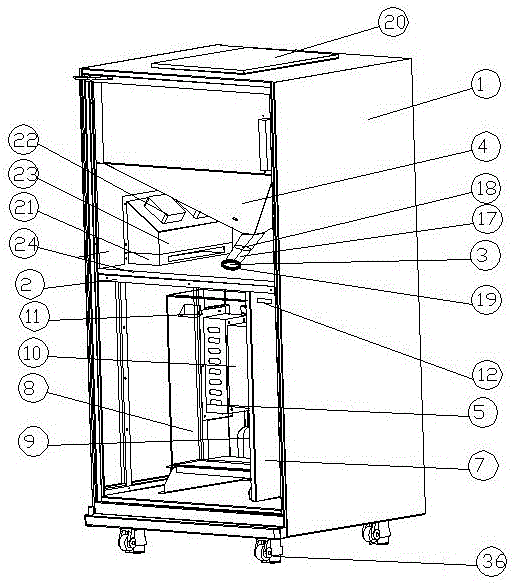

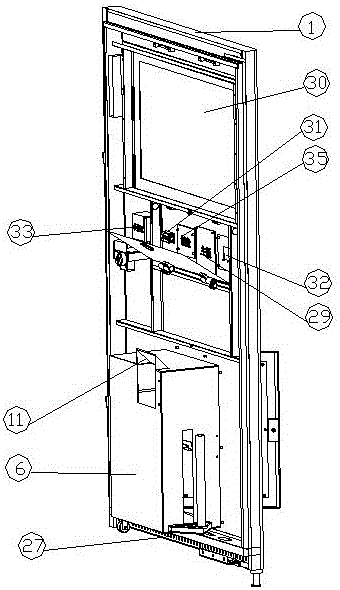

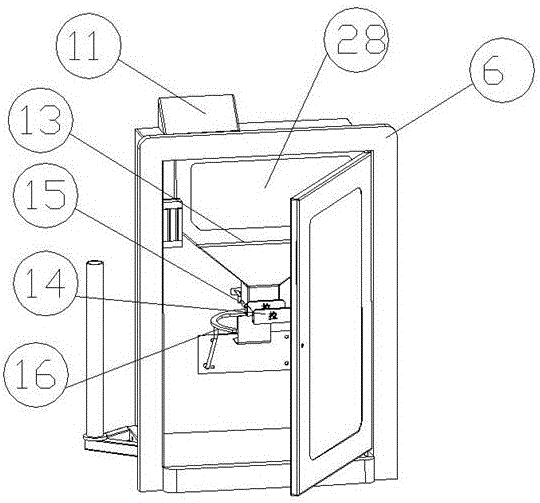

[0021] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Show a kind of specific embodiment of the present invention: a kind of automatic fresh rice machine, comprise cabinet 1, be provided with intermediate sealing partition 2 in cabinet 1, the center of central sealing partition is provided with round hole 3, the middle sealing partition 2 A grain hopper 4 is arranged on the top, a rice grinding unit 5 is arranged on the bottom, and a rice extraction cabinet 6 and a rice bran cabinet 7 are arranged in the cabinet 1, and the rice extraction cabinet 6 and the rice bran cabinet 7 are respectively arranged on the front side of the rice grinding unit 5 and On the right side, the rice milling unit 5 includes a rice mill 8, an air compressor 9 and a heat exhaust fan 10. The rice mill 8 is provided with a rice outlet 11 and a bran outlet 12, and the rice outlet 11 is connected to the rice taking cabinet 6. Connection, the bran outlet 12 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com