Directional motion control method of semiconductor micro-nano particles

A technology of micro-nano particles and directional movement, applied in radiation/particle processing, manipulation of neutral particles by radiation pressure, nuclear engineering, etc., to achieve high control precision, wide application range, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

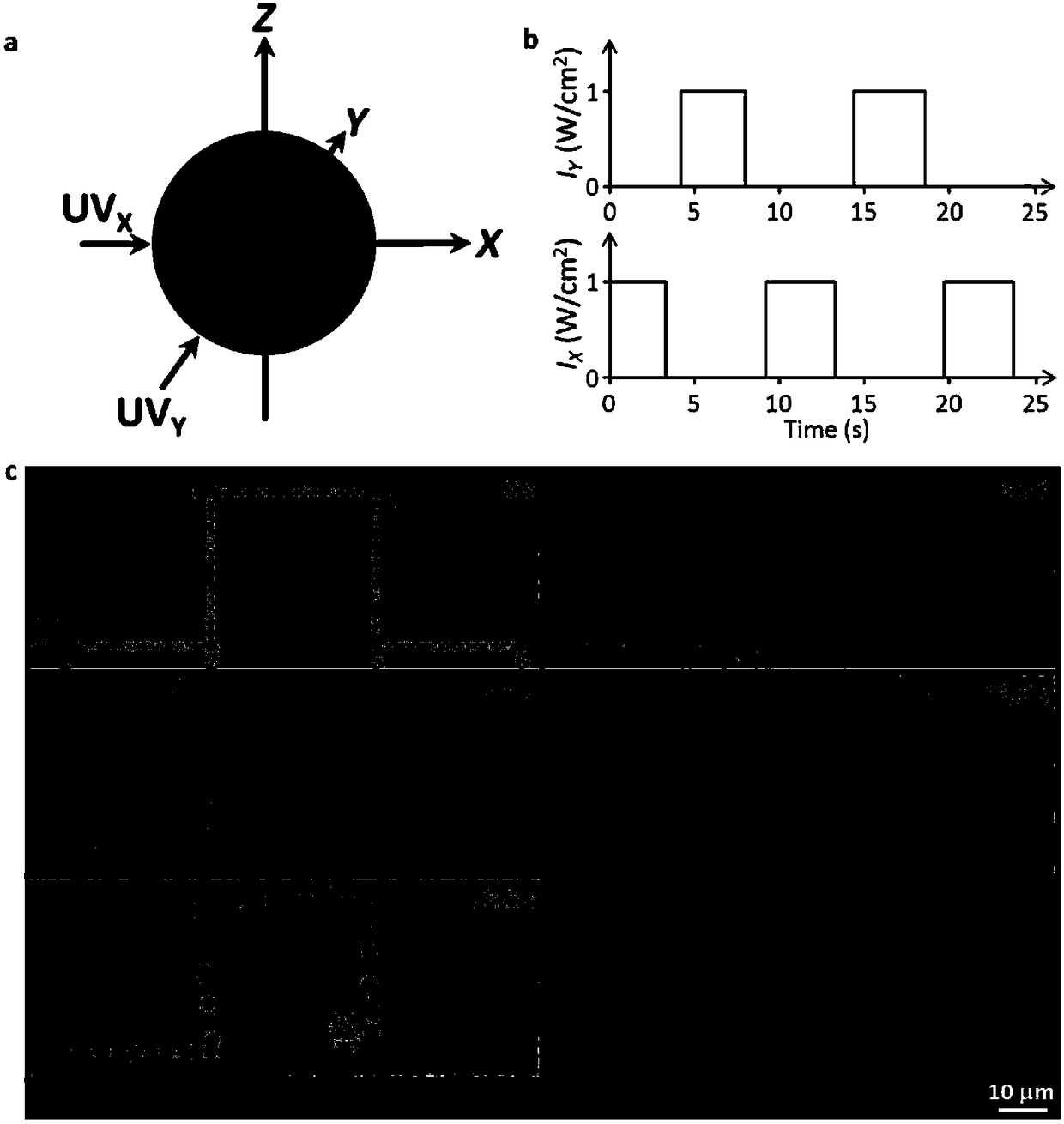

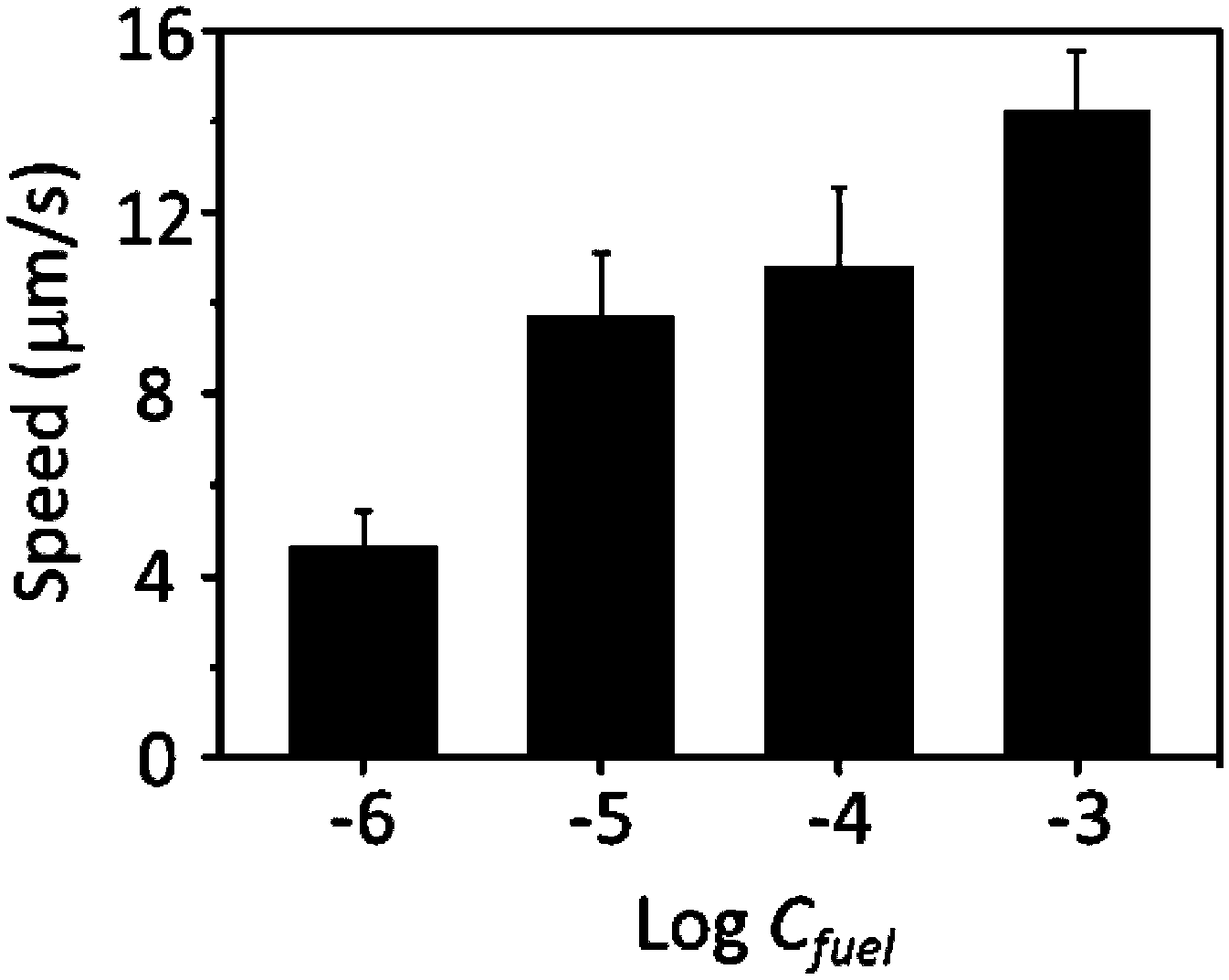

[0038] A control method for optically controlling the movement of titanium dioxide micro / nano microspheres, which comprises the following steps: dispersing titanium dioxide microspheres into a certain concentration of hydrogen peroxide fuel (0.000001-1wt.%), according to figure 1 Build an illumination platform, set the angle between the light and the horizontal plane to be θ (0°≤0≤90°), and set the output power of the light source to 1W, then the negative phototaxis motion of titanium dioxide microspheres can be obtained. Among them, (a) is a schematic diagram of ultraviolet light irradiating semiconductor micro-nano particles. UV X and UV Y are the projections of light X and Y on the X-Y plane, respectively. (b) Schematic diagram of the switching cycle of light sources X and Y. (c) is a time series photograph of a typical titanium dioxide spherical micro-particle moving in 0.001wt.% hydrogen peroxide solution, and the dotted line indicates the preset moving route of the ti...

Embodiment 2

[0045] An ultraviolet light emitting device was built according to the conditions in Example 1, and the movement properties of titanium dioxide microspheres with particle diameters of 400 nm, 1.2 μm and 3.5 μm were respectively tested. Under the condition of hydrogen peroxide concentration of 0.001wt%, particles with a particle size of 400nm and 3.5μm only exhibited random Brownian motion, indicating that the product concentration difference between the illuminated side and the backlit side of the particle cannot drive the particle to move, such as Figure 4 shown. When the concentration distribution of hydrogen peroxide increased to 0.1wt% and 0.66wt%, the particles with particle size of 400nm and 3.5μm began to show negative phototaxis motion.

Embodiment 3

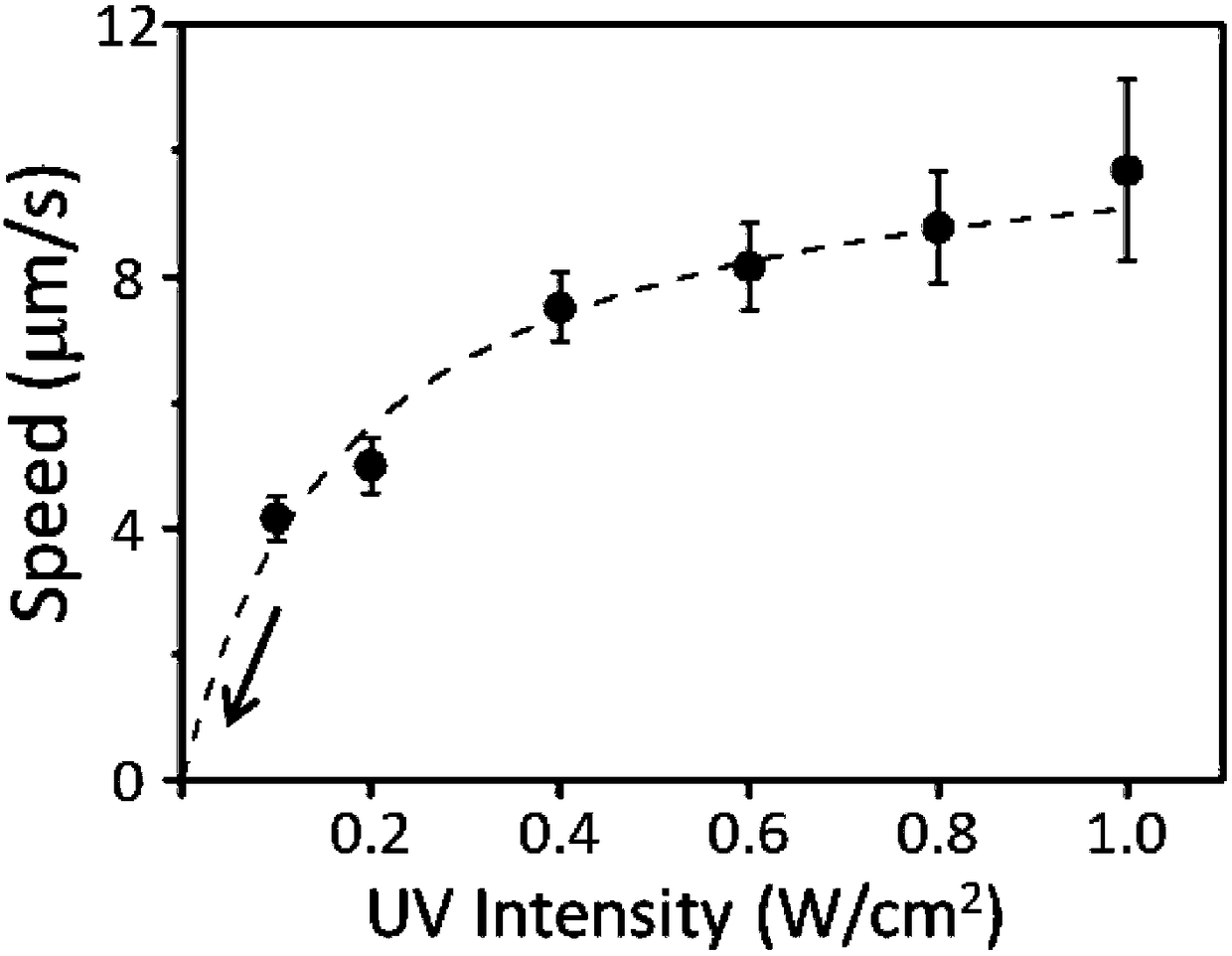

[0047] Build an ultraviolet light emitting device according to the conditions in Example 1, adjust the value of the included angle θ of the ultraviolet light source on the horizontal plane, use ultraviolet light with a power of 1W to irradiate the particles, and find that the movement speed of the particles changes with the change of the included angle θ, as shown in Figure 5 As shown, when θ=0°, the particle loses the ability of directional movement, and only shows random movement without direction. The reason for this phenomenon is that the product concentration distribution near the particle is evenly distributed around the particle under this lighting condition.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap