A Coaxial Spin Injection Device

A spin injection, coaxial technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem of holes, reduce the efficiency of spin injection, and the effective contact area between the spin injection electrode and the channel is not controllable. Improves efficiency, improves controllability and reliability, reduces effects of electron scattering problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

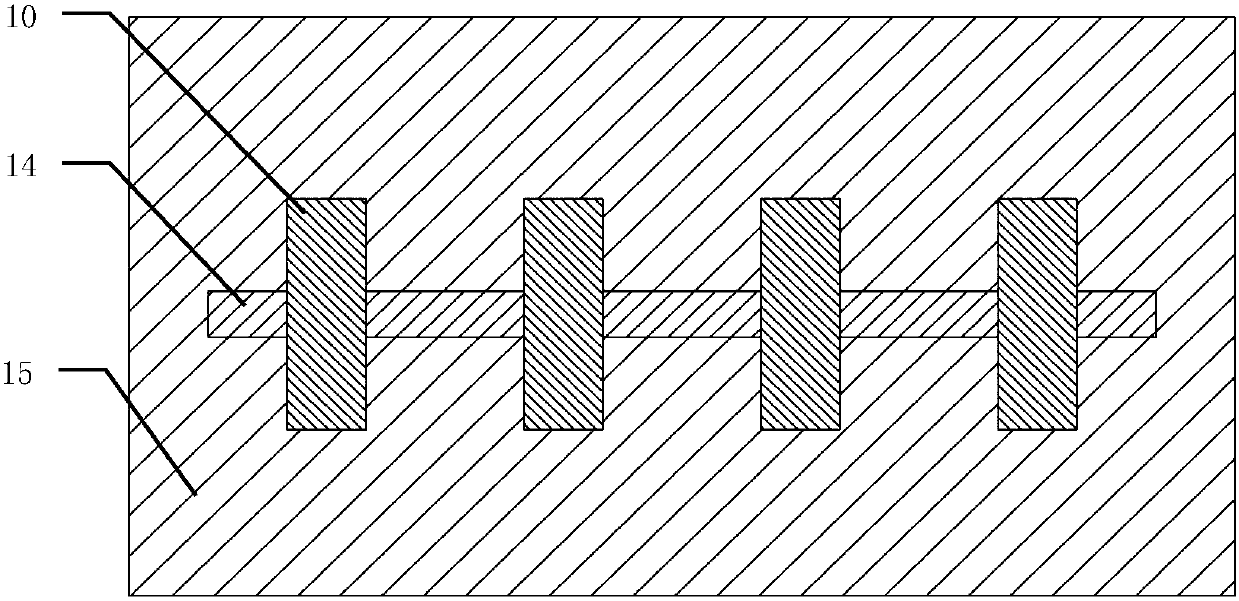

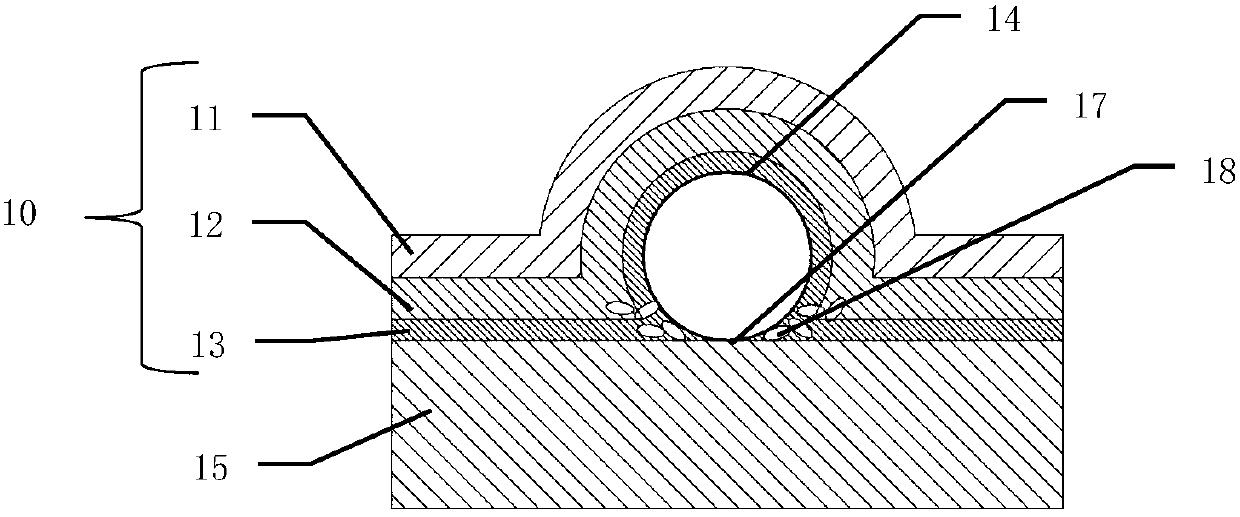

[0041] In the embodiment of the present invention, we use coaxial spin injection electrodes to solve the above two problems. The specific implementation is as follows:

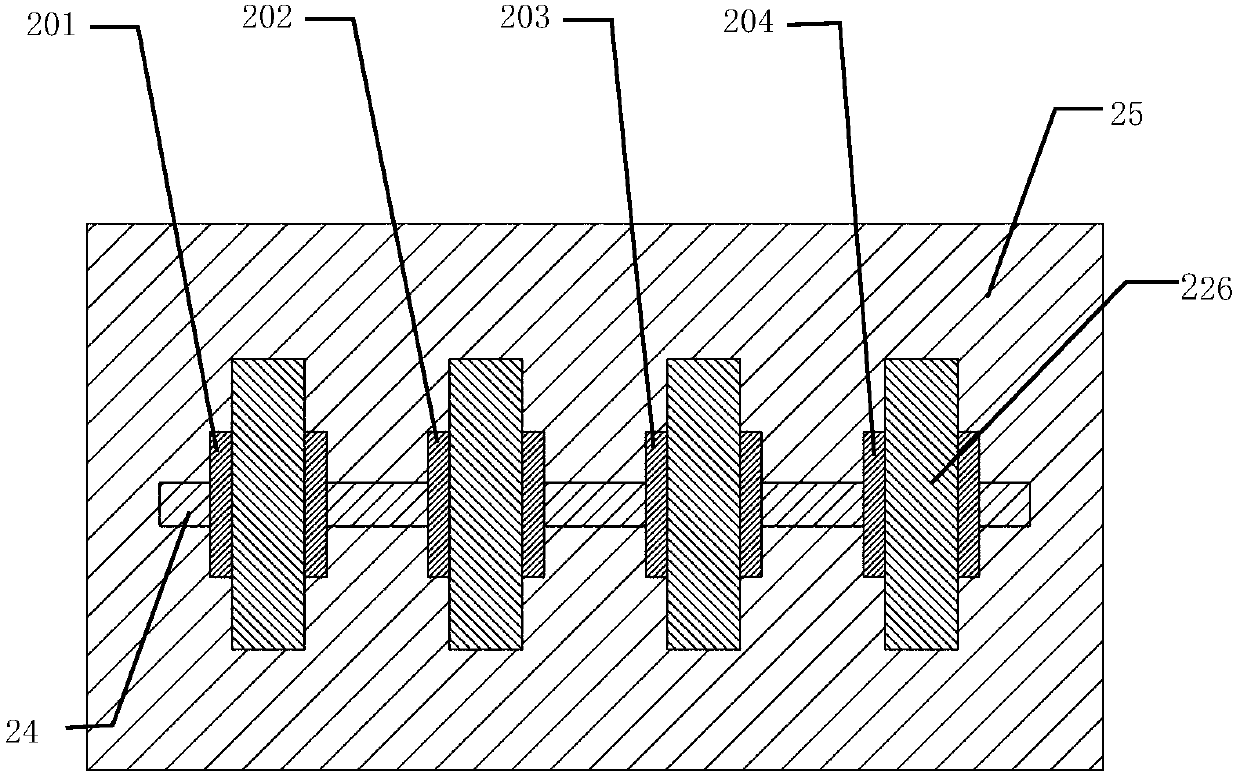

[0042] Figure (2) is a top view of the coaxial spin injection device, and Figure 2(b) is a cross-sectional view of Figure 2(a). As shown in FIG. 2( a ) and FIG. 2( b ), four coaxial spin injection electrodes 201 , 202 , 203 , and 204 are sequentially arranged on the carbon nanotube 24 . In this embodiment, the carbon nanotubes 24 include single-wall carbon nanotubes and multi-wall carbon nanotubes, with a diameter of 0.3-100 nm and a length of 0.001-100 mm. Metal nanowires including silver nanowires, copper nanowires, or other one-dimensional materials may also be used. The coaxial spin injection electrode is composed of a coaxial tunneling layer 23 , a coaxial ferromagnetic layer 22 and a coaxial cladding layer 21 . Among them, the coaxial tunneling layer 23 includes magnesium oxide (MgO), aluminum nitride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com