Power battery pack

A power battery pack and sliding seat technology, applied in battery pack components, circuits, electrical components, etc., can solve problems such as affecting productivity, difficulty in aligning installation holes, trouble, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

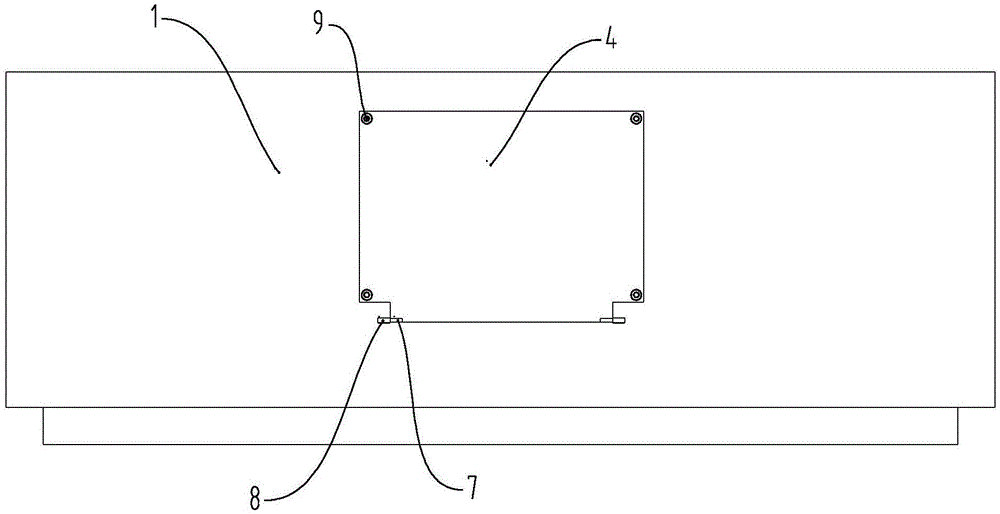

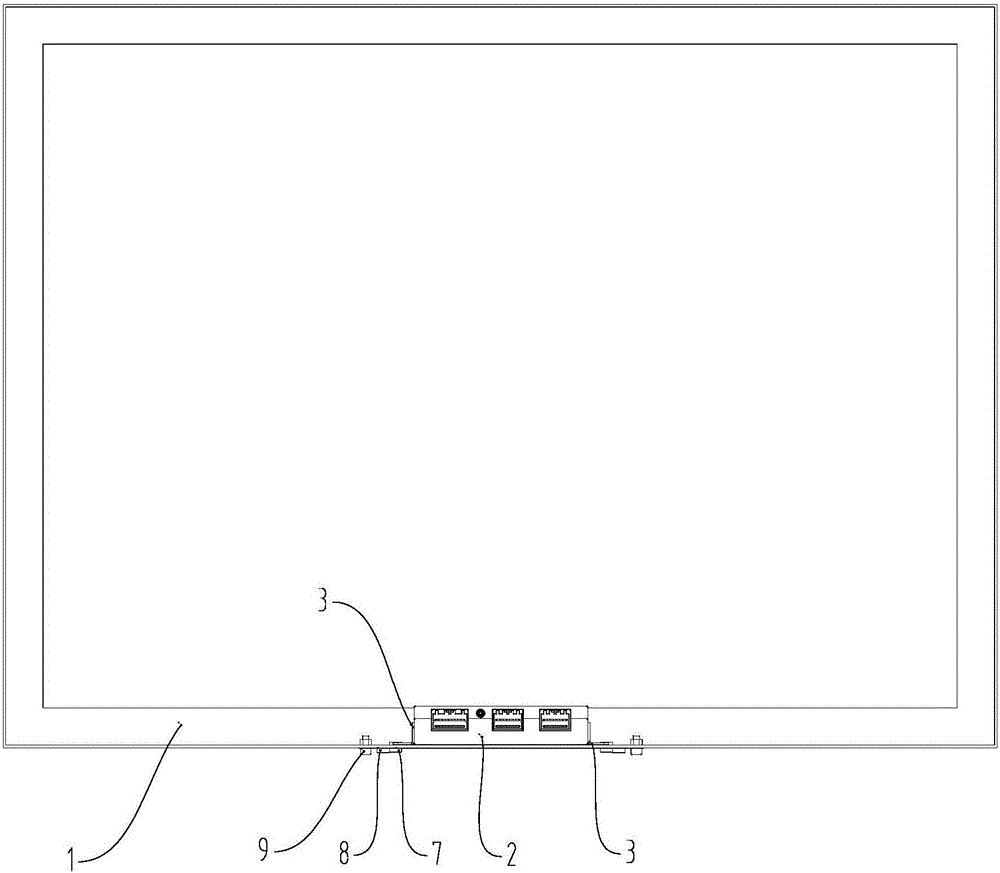

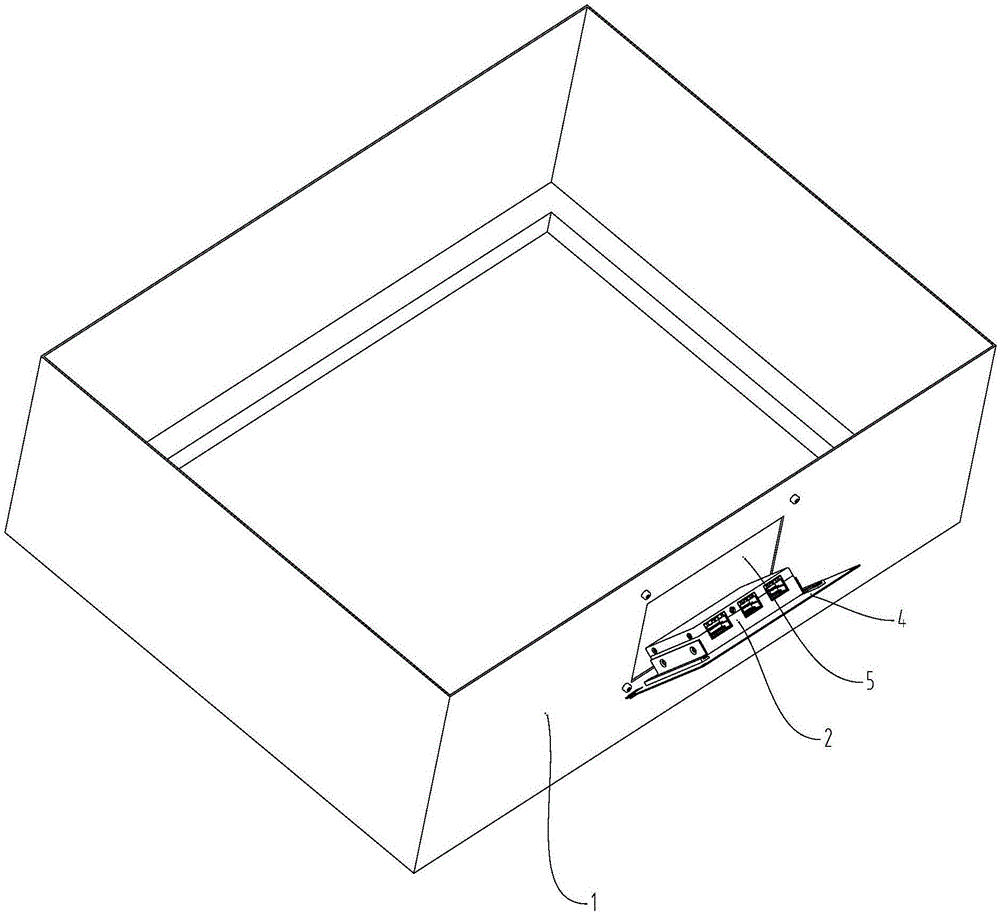

[0034] like Figure 1 to Figure 8 shown, figure 1 It is a schematic diagram of the front view structure of a power battery pack provided by the present invention; figure 2 for figure 1 The top view of the power battery pack shown; image 3 for figure 1 The schematic diagram of the three-dimensional structure of the power battery pack shown; Figure 4 for figure 1 A schematic diagram of the three-dimensional structure of the power battery pack shown in another angle; Figure 5 for figure 1 Another perspective schematic diagram of the three-dimensional structure of the power battery pack shown in ; Image 6 for Figure 5 Partial enlarged view of A in the center; Figure 7 It is a schematic diagram of instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com