A Parallel Dual-Stator Hybrid Excitation Permanent Magnet Motor

A hybrid excitation, permanent magnet motor technology, applied in electromechanical devices, electrical components, magnetic circuit rotating parts, etc., can solve problems such as low speed and large torque, and achieve high motor speed, high reliability, and high energy utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

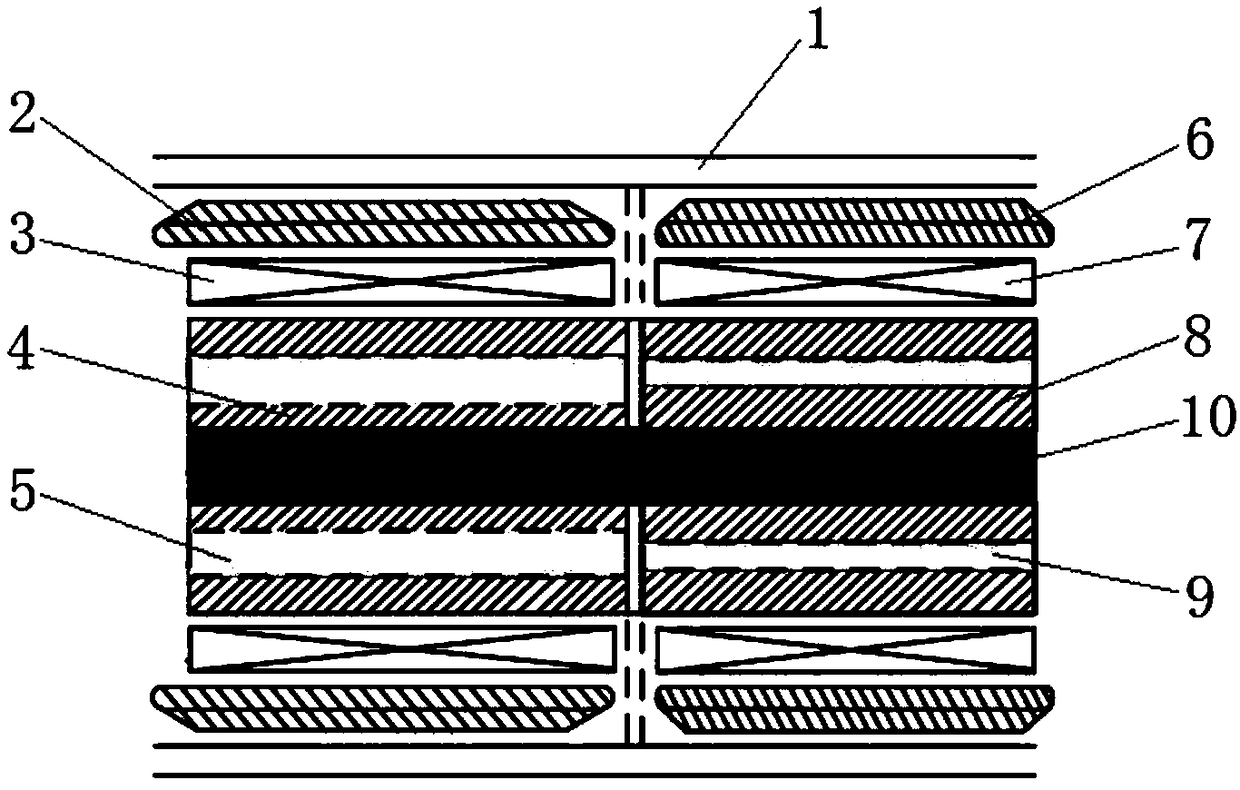

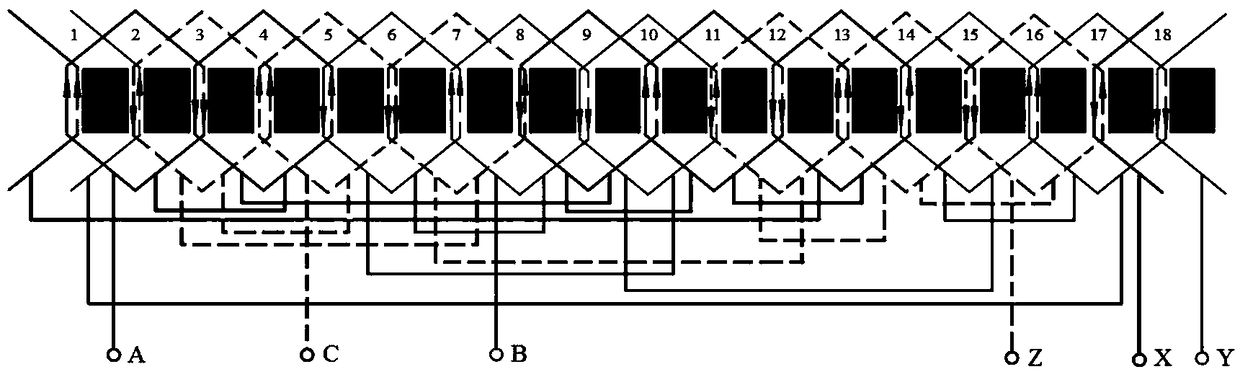

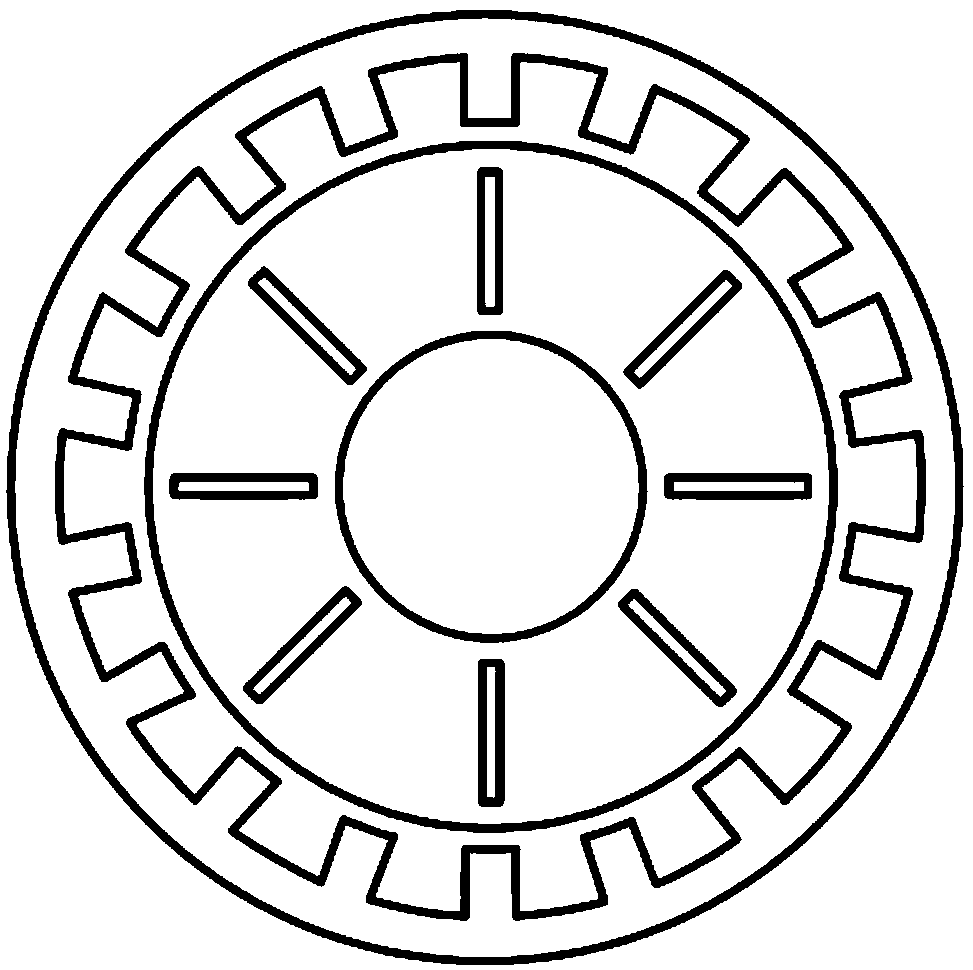

[0035] Combine figure 1 As shown, a parallel dual-stator hybrid excitation permanent magnet motor of this embodiment includes a housing 1, a motor group A and a motor group B arranged in parallel in the housing 1, wherein the motor group A includes a stator A 2 and a rotor A 4. The stator A2 is fixed in the housing 1, the rotor A4 is located in the stator A2 and is mounted on the shaft 10, the stator A2 has a high back-EMF winding A3, and the rotor A4 has a permanent magnet A5. A 5 is a neodymium iron boron permanent magnet. Motor group A chooses a low-speed, high-torque operating point as rated operating point A, and when the speed of motor group A exceeds rated operating point A, field weakening control is adopted for motor group A It can not only obtain a large starting torque, but also increase the motor speed and expand the constant power operation area. The motor group B includes a stator B 6 and a rotor B 8. The stator B 6 is fixed in the housing 1, and the rotor B 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com