A method of manufacturing an earphone head

A manufacturing method and headphone head technology, applied in the direction of sensors, electrical components, etc., can solve the problems of easy wear of the paint layer, damage to the appearance of the earphone shell, erosion and discoloration, etc., and achieve good optics, improve the effect of sound quality and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

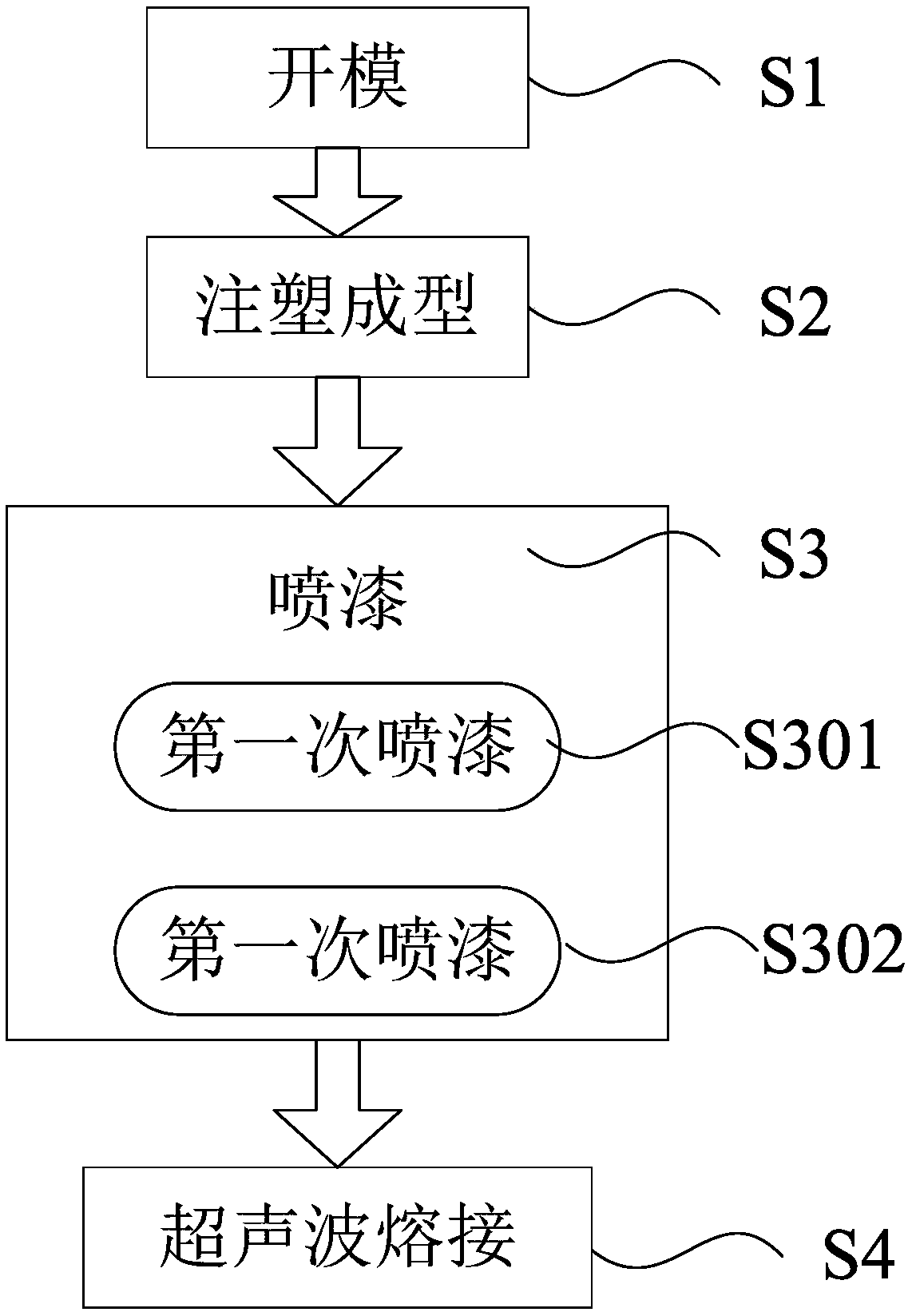

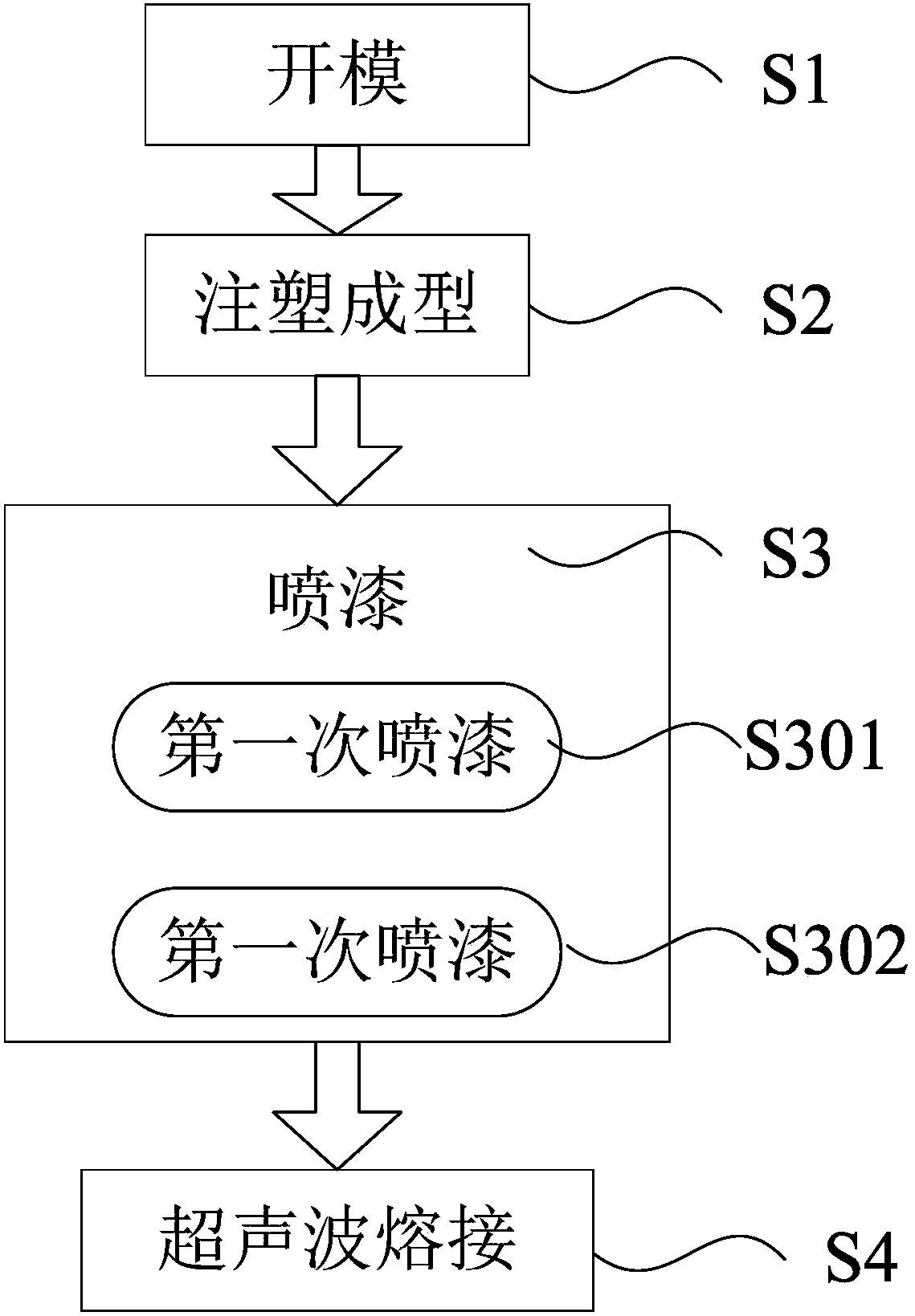

[0024] Such as figure 1 Shown, a kind of headphone head manufacturing method comprises the following steps:

[0025] S1: Mold opening, use 3D printer and 3D software to design the internal structure of the earphone head, the structure of the upper shell and the lower shell and open the mold;

[0026] Include the following steps in S1:

[0027] S101, first print the 3D headphone head model with a 3D printer, confirm the comfort of the headphone head, and analyze the production feasibil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com