Injection system and method for operating an injection system

An injection system and injector technology, applied in the direction of charging system, fuel injection control, engine components, etc., can solve the problems of pressure pulsation, adverse effects on injector metering accuracy, noise generation, etc., and achieve precise injection amount metering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

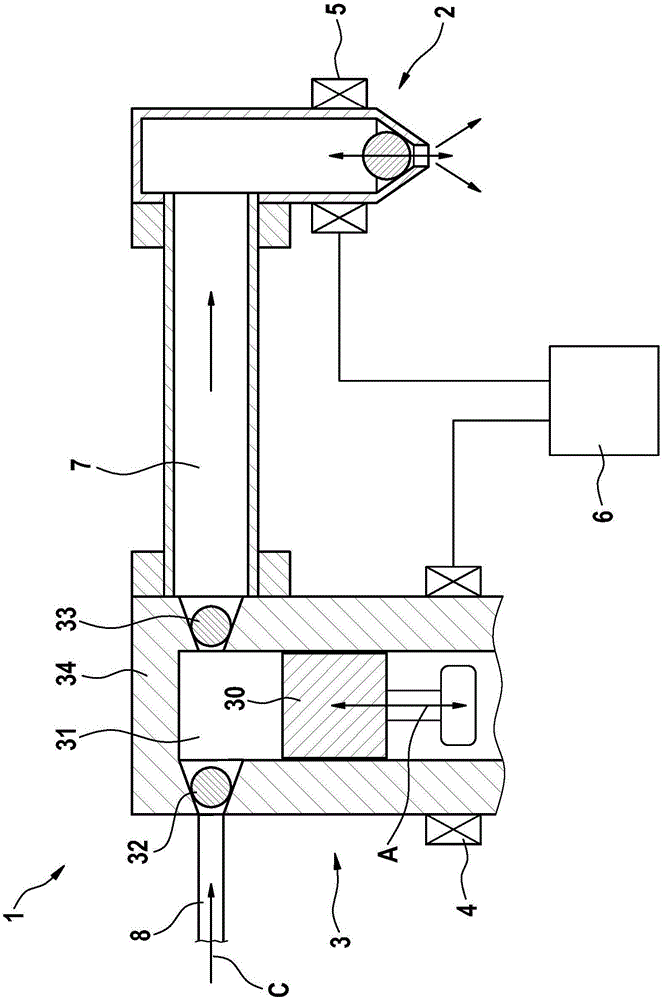

[0023] Refer to the appendix below Figures 1 to 3 The injection system 1 according to the preferred embodiment of the present invention is described in detail.

[0024] The injection system 1 includes an injector 2 and a piston pump 3 . The piston pump 3 is connected to the injector 2 via a pressure line 7 .

[0025] Piston pump 3 in figure 1 It is only schematically shown in , and includes a reciprocating piston 30 (double arrow A) in a cylinder 34 , a delivery chamber 31 , an inlet valve 32 and an outlet valve 33 . The pressure line 7 is here arranged downstream of the outlet valve 33 in the fuel flow direction.

[0026] Reference numeral 8 designates a fuel supply line, via which fuel can be drawn into the delivery chamber 31 in a known manner via an open inlet valve 32 (arrow C).

[0027] The piston pump 3 is operated by means of a first actuator 4 . The second actuator 5 is provided for operating the injector 2 .

[0028] like figure 1 As can be seen, the first ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com