Data processing device for x-ray inspection, and x-ray inspection device equipped with the same

A data processing device, X-ray technology, applied in image data processing, measuring device, clinical application of radiological diagnosis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

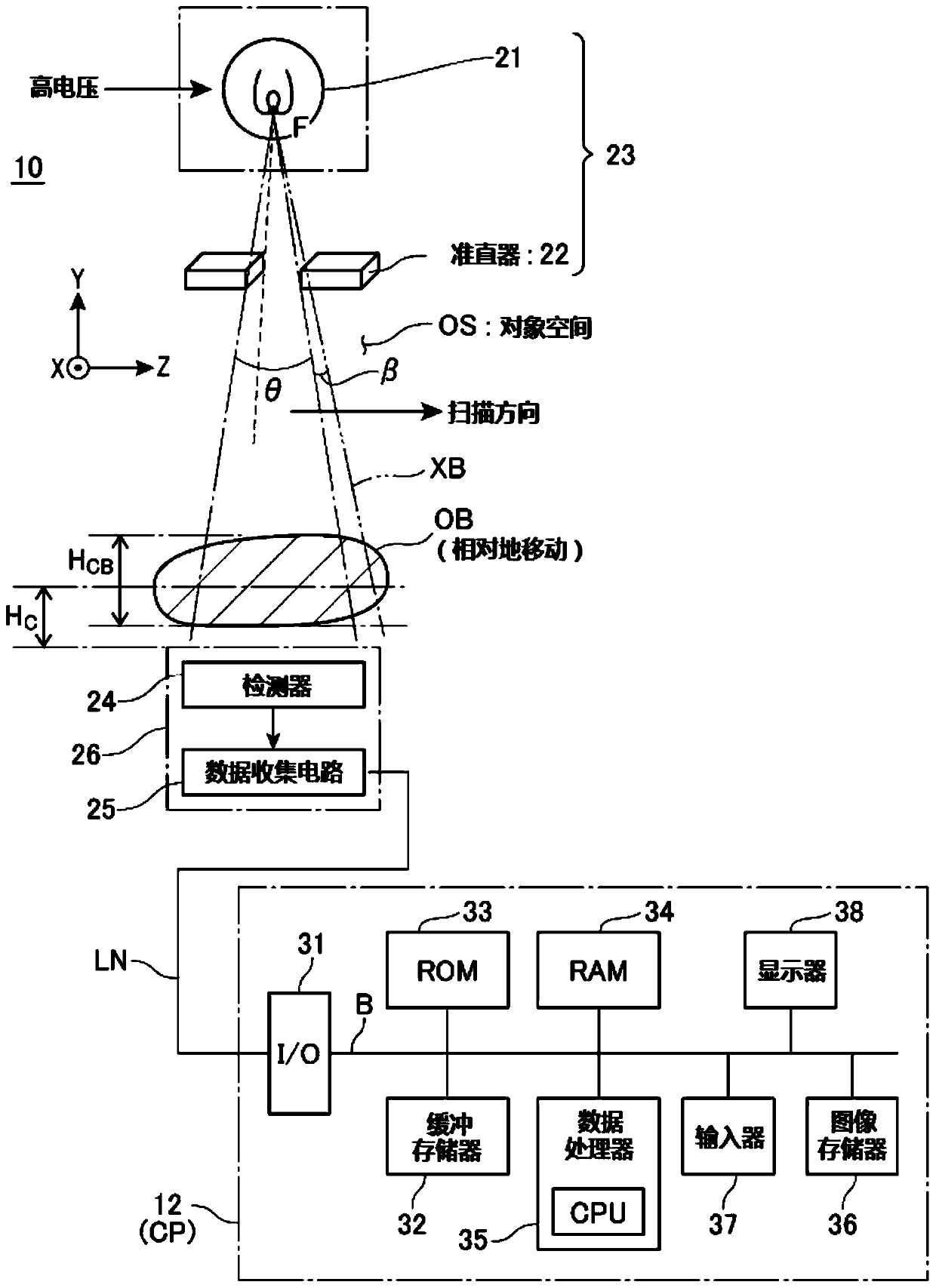

[0062] First, as an embodiment, refer to Figure 1 to Figure 15 An embodiment of a data processing device and a data processing method for X-ray inspection according to an aspect of the present invention will be described. figure 1 The schematic structure of the X-ray inspection system (X-ray inspection apparatus) 10 is shown. In this embodiment, the data processing device and the data processing method are focused on the description, so the known parts of the X-ray inspection system 10 will be briefly described.

[0063] A data processing device 12 is communicably connected to the X-ray inspection system 10 via a communication line LN. The data processing device 12 may be integrated with, for example, a control unit of the X-ray inspection system 10, or may be provided separately.

[0064] The X-ray inspection system 10 is used, for example, as an X-ray-based non-destructive inspection system or a medical X-ray panoramic imaging system. As inspection objects of the X-ray inspectio...

Deformed example 2

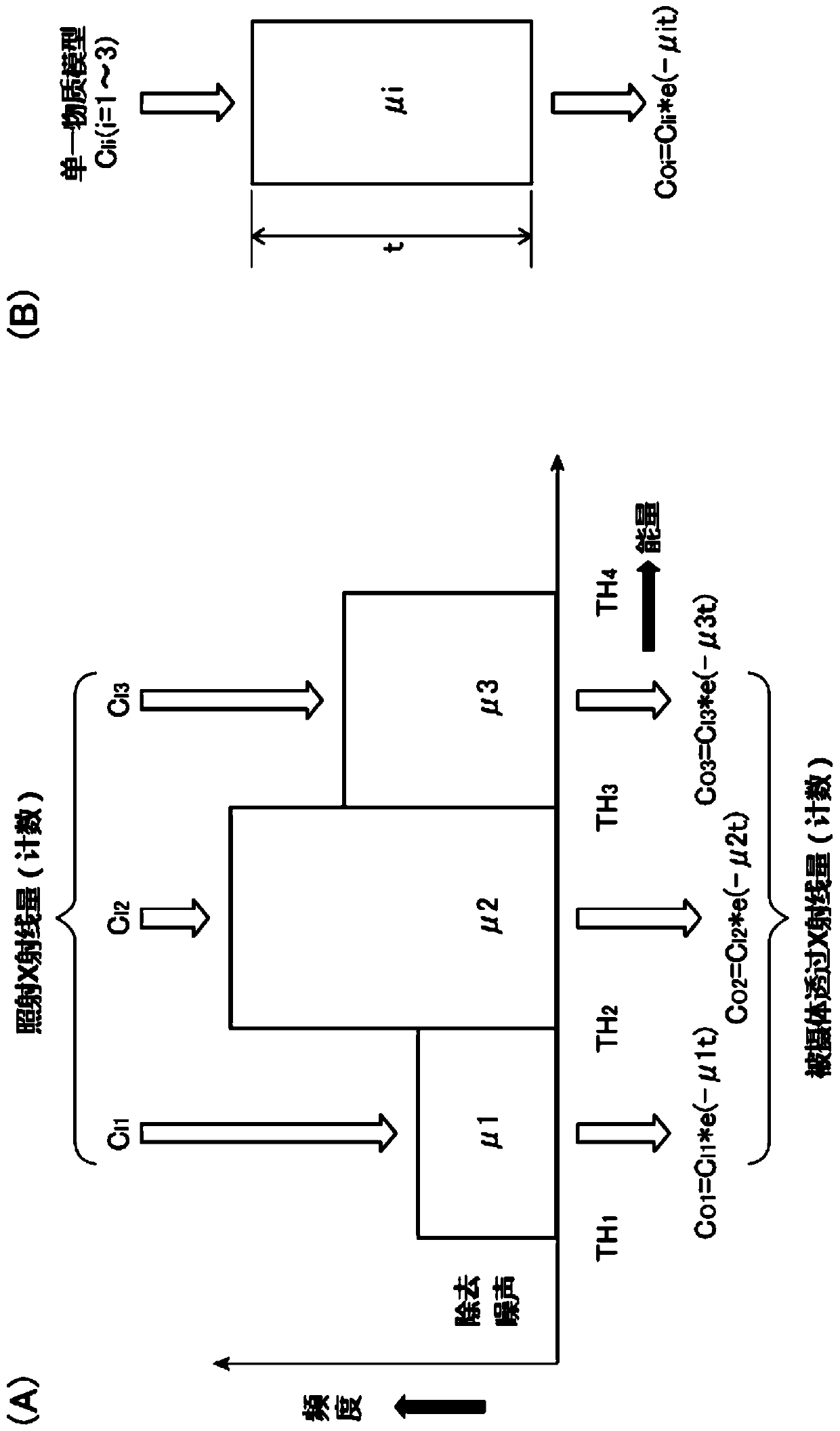

[0199] In addition, the calculation formula (8) used to create the above-mentioned absorption vector long image may be generalized into the following form.

[0200] (a×(μ 1 t) 2 +b×(μ 2 t) 2 +c×(μ 3 t) 2 ) 1 / 2 ……(8')

[0201] Here, a, b, and c are coefficients of arbitrary values used for weighting calculation. The absorption vector length image created according to this calculation formula can be used to design the irradiation conditions of the X-ray tube, etc. By designing the irradiation conditions, the X-ray tube can be irradiated with X-rays having an incident energy spectrum corresponding to the type and specific gravity of the substance to be inspected, for example.

Deformed example 3

[0203] In addition, as another modification, Figure 16 The X-ray inspection apparatus according to the present invention is shown as an example of a medical rheumatism inspection apparatus. Such as Figure 16 As shown, the rheumatism inspection apparatus 118 is provided with a scanned image moving mechanism 120 that uses the joints of the subject’s hand as the inspection object OB, and separates the X-ray generator 121 from the photon counting detection unit 126 Facing the joint, and the pair of X-ray generators 121 and the photon counting detection unit 126 Figure 16 Move in the front and back direction of the paper. The rheumatism inspection device 118 further includes: a reconstruction unit 111 that processes the frame data output from the detection unit 126; a data processing device 112 that receives reconstruction information from the reconstruction unit 111 and performs the above-mentioned substance determination processing; and a display monitor 138. Display the proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com