Swinging disc type oil cylinder motor

A swing disc type, swing disc technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of poor reliability, high cost, affecting the life of hydraulic motors, etc., to reduce wear and oil leakage, reduce rotating parts, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

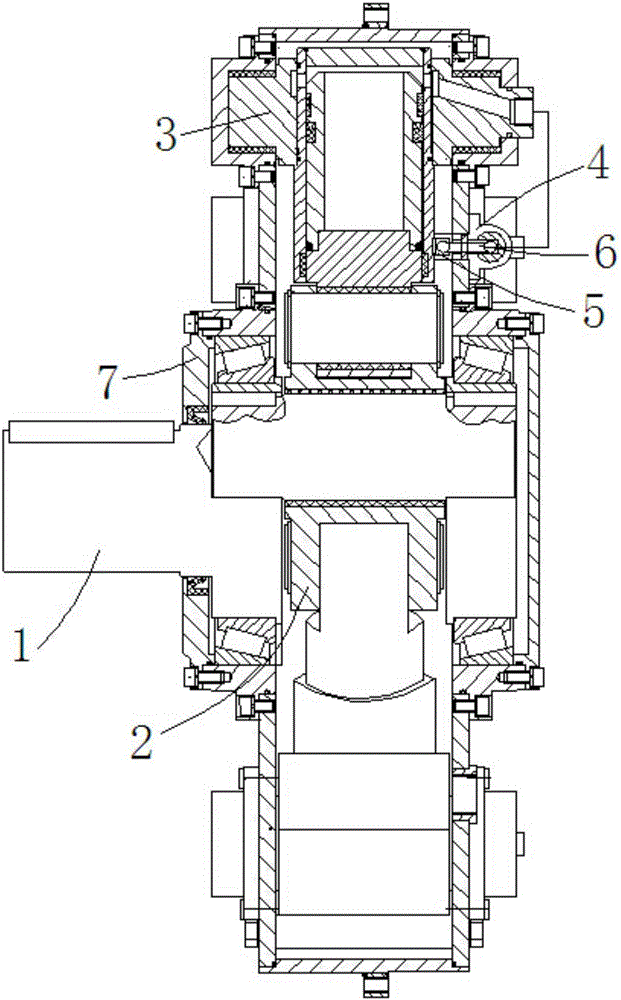

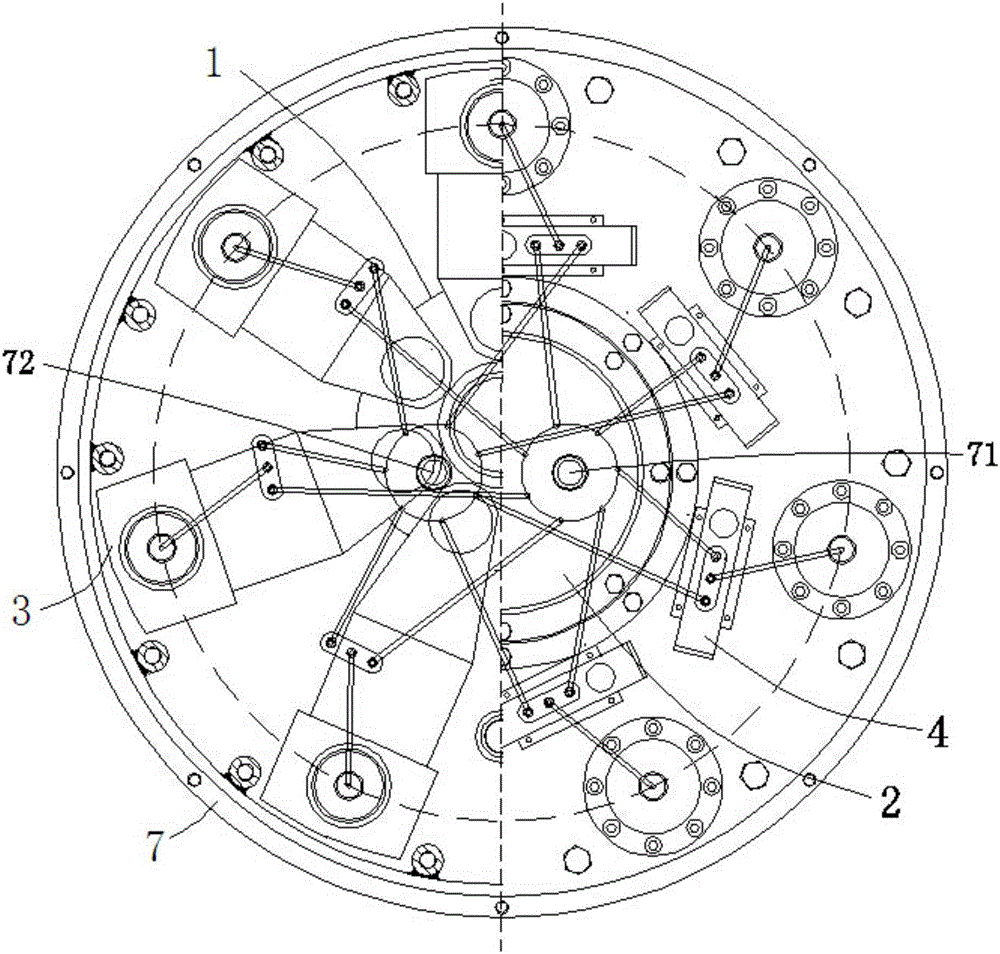

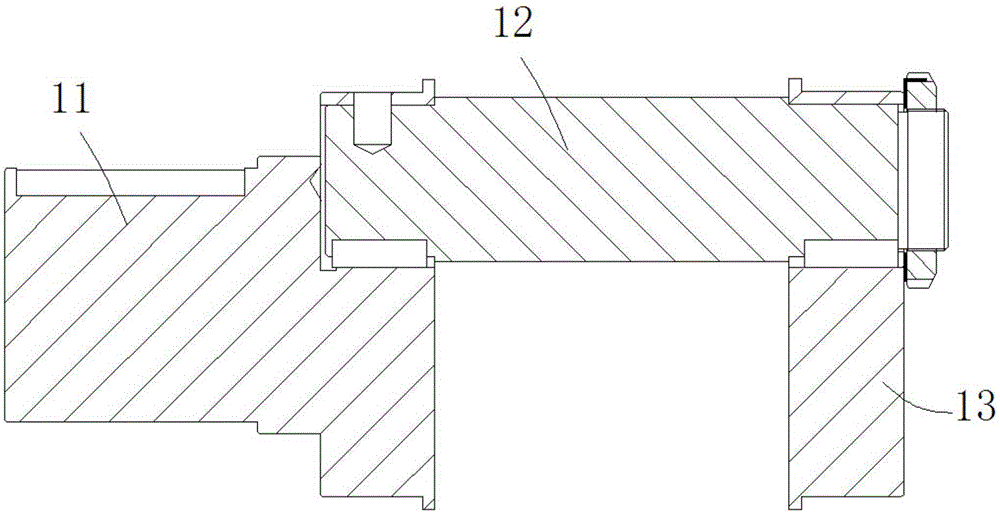

[0027] refer to figure 1 and figure 2 , The oscillating disc cylinder motor of the present invention includes a crankshaft 1, a oscillating disc 2, an oil cylinder 3, an oil distribution valve 4, a shift fork 5, a connecting rod 6 and a housing 7. Among them, the oscillating plate 2 is installed on the crankshaft 1 with bearings, and there are multiple oil cylinders 3, and the multiple oil cylinders 3 are all connected to the oscillating plate 2, and each oil cylinder 3 is connected to an oil distribution valve 4, and the shift fork 5 is installed on the oil cylinder 3 , one end of the connecting rod 6 is connected with the oil distribution valve 4, and the other end is connected with the shift fork 5, the crankshaft 1, the oil cylinder 3 and the oil distribution valve 4 are all installed on the housing 7, and the housing 7 is also provided with an oil inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com