Multi-channel electromagnetic ultrasonic thickness measuring system

An electromagnetic ultrasonic and multi-channel technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of full-coverage and fast-scanning limitations of pipelines, achieve rapid automatic thickness measurement, simple system structure, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

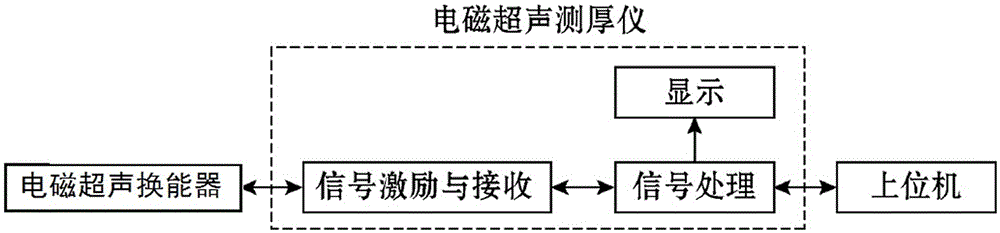

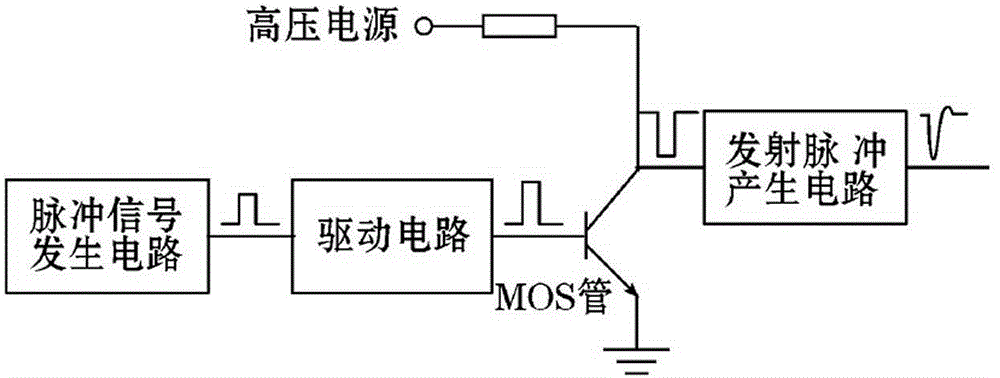

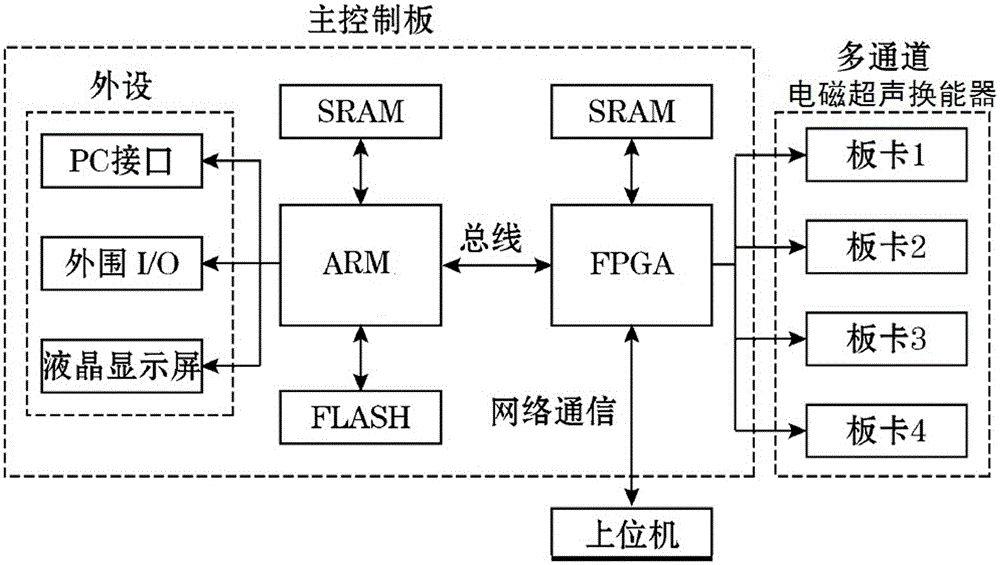

[0015] to combine figure 1 and figure 2 As shown, the present invention includes an electromagnetic ultrasonic transducer, an electromagnetic ultrasonic thickness gauge, and a host computer; the key points of its structure are: the electromagnetic ultrasonic thickness gauge includes a signal excitation and receiving module, a signal processing module, and a display module, and the signal The excitation and receiving module and the signal processing module are connected to each other, and the output end of the signal processing module is connected to the display module; the signal excitation of the electromagnetic ultrasonic thickness gauge and the input end of the receiving module are connected to the signal output end of the electromagnetic ultrasonic transducer. The signal processing module is connected to the upper computer; the signal excitation module includes a pulse signal generating circuit, a driving circuit, a MOS tube, and a transmission pulse generating circuit, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com