Industrial camera cylinder detection method

A detection method and technology of industrial cameras, which are applied in measurement devices, material analysis by optical means, instruments, etc., can solve problems such as large space, high cost, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The working principle of the present invention is as follows:

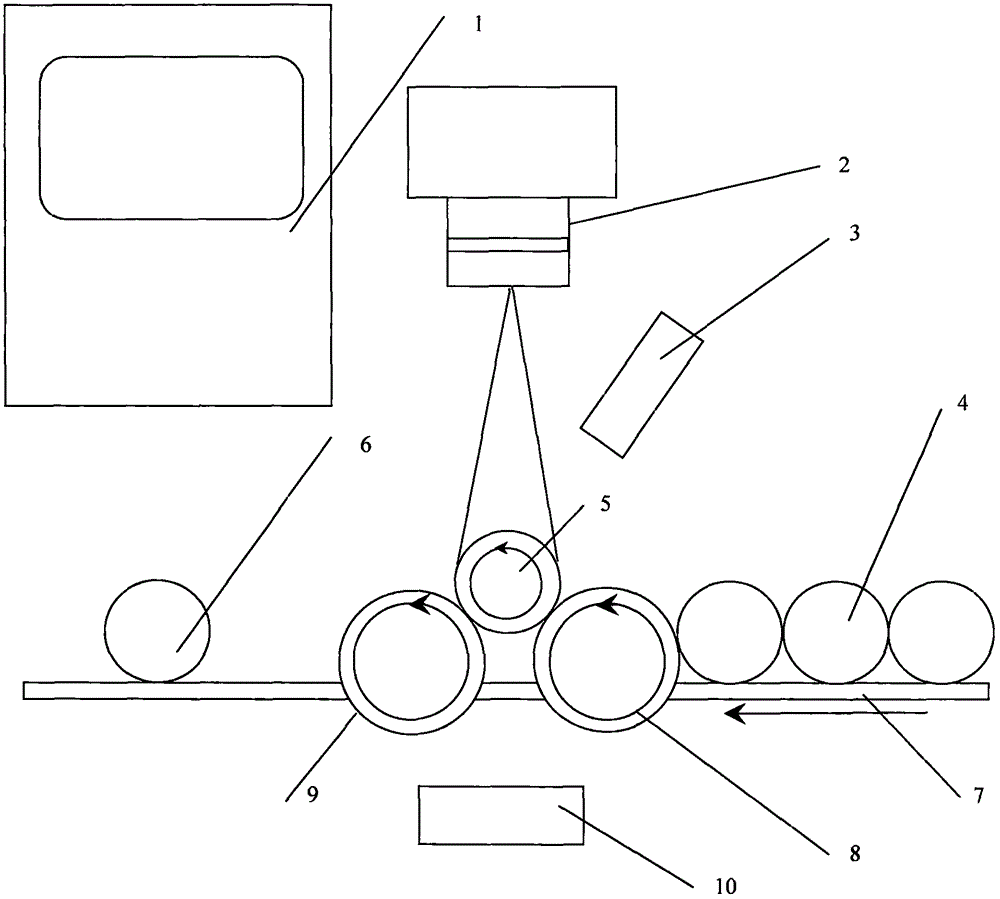

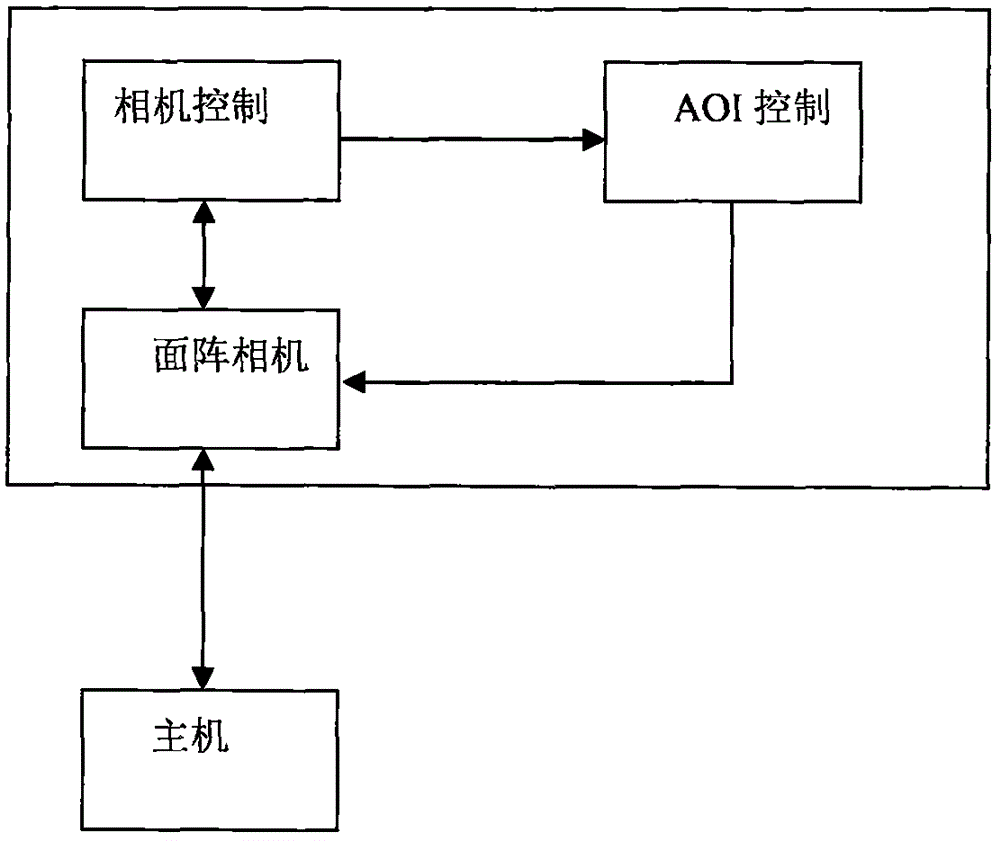

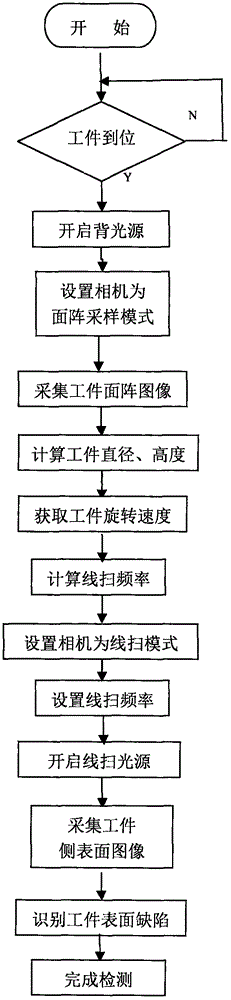

[0025] as attached figure 1 , attached figure 2 And attached image 3 As shown: the workpiece 4 to be inspected is transmitted to the feeding driving wheel 8 by the driving synchronous belt 7, and the workpiece is transmitted to the inspection station 5 by the feeding driving wheel 8. Rotate under the drive of 9, turn on the backlight 10 at this time, set the camera 2 to work as the area array sampling mode, collect the surface array image of the outer contour of the workpiece 5 under inspection, and calculate the diameter and height of the workpiece 5 under inspection; subsequently, by and The encoder with the drive wheel 8 coaxially obtains the rotation speed of the workpiece, calculates the line scan frequency, changes the camera to work in line array mode, sets the line scan frequency, turns on the line scan light source 3, collects the side surface image of the workpiece 5, and identifies the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com