Mud cake bagging method and device for chamber type filter press

The technology of a box-type filter press and bagging device is applied in separation methods, chemical instruments and methods, filtration and separation, etc. It can solve the problems of poor practicability, high cost, and non-universal use, so as to protect safety and health , low cost, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

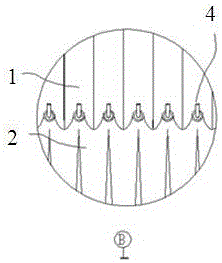

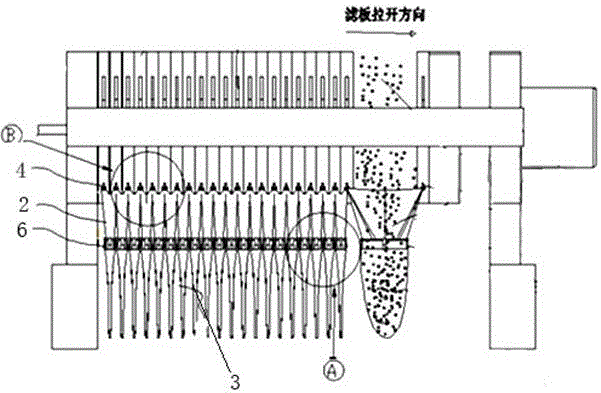

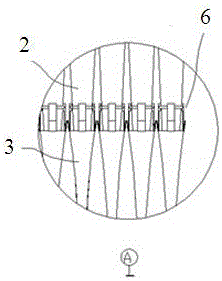

[0029] Below in conjunction with accompanying drawing this invention is further described: a kind of chamber type filter press mud cake bagging device, comprises opening foldable mud guiding device 2 and loading bag 3, wherein mud guiding device 2 is fixed on filter press filter plate 1 Below, the opening covers the mud falling area between the two filter plates, it opens as the filter plate 1 of the filter press opens, and closes as the filter plate 1 closes; the loading bag 3 is fixed below the mud guide device 2, and the bag mouth is connected The mud outlet of the mud guide device 2 is butted.

[0030] Further, the number of mud guide devices 2 and the number of loading bags 3 are determined according to the number of filter plates 1 of the filter press, a mud guide device 2 is arranged between every two filter plates, and a load bag is installed under each mud guide device 2 3.

[0031] Further, both sides of the lower end of each filter plate 1 are provided with connect...

Embodiment 2

[0037] A box-type filter press mud cake bagging device, comprising a mud guide device 2 with a foldable opening and a loading bag 3, wherein the mud guide device 2 is fixed below the filter plate 1 of the filter press, and the opening covers the gap between the two filter plates The mud falling area opens with the opening of the filter plate 1 of the filter press, and closes with the closing of the filter plate 1; the loading bag 3 is fixed under the mud guide device 2, and the bag mouth is docked with the mud outlet of the mud guide device 2.

[0038] Further, the number of mud guide devices 2 and the number of loading bags 3 are determined according to the number of filter plates 1 of the filter press, a mud guide device 2 is arranged between every two filter plates, and a load bag is installed under each mud guide device 2 3.

[0039] Further, both sides of the lower end of each filter plate 1 are provided with connectors 4, and the opening of each mud guide device 2 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com