Gas-liquid mixing apparatus

A gas-liquid mixing and liquid technology, applied in the direction of mixers, mixing methods, fluid mixers, etc., can solve problems such as inability to achieve uniform mixing, not using multi-point mixing, unfavorable movement of gas-liquid mixture, etc., to improve independence , improve the mixing effect, improve the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention provides a gas-liquid mixing device, which improves the independence of the device and further improves the mixing uniformity, so that the mixing of gas-liquid materials becomes standardized, uniform and controllable, thereby improving the mixing effect. The present invention will be described in further detail below in conjunction with the accompanying drawings.

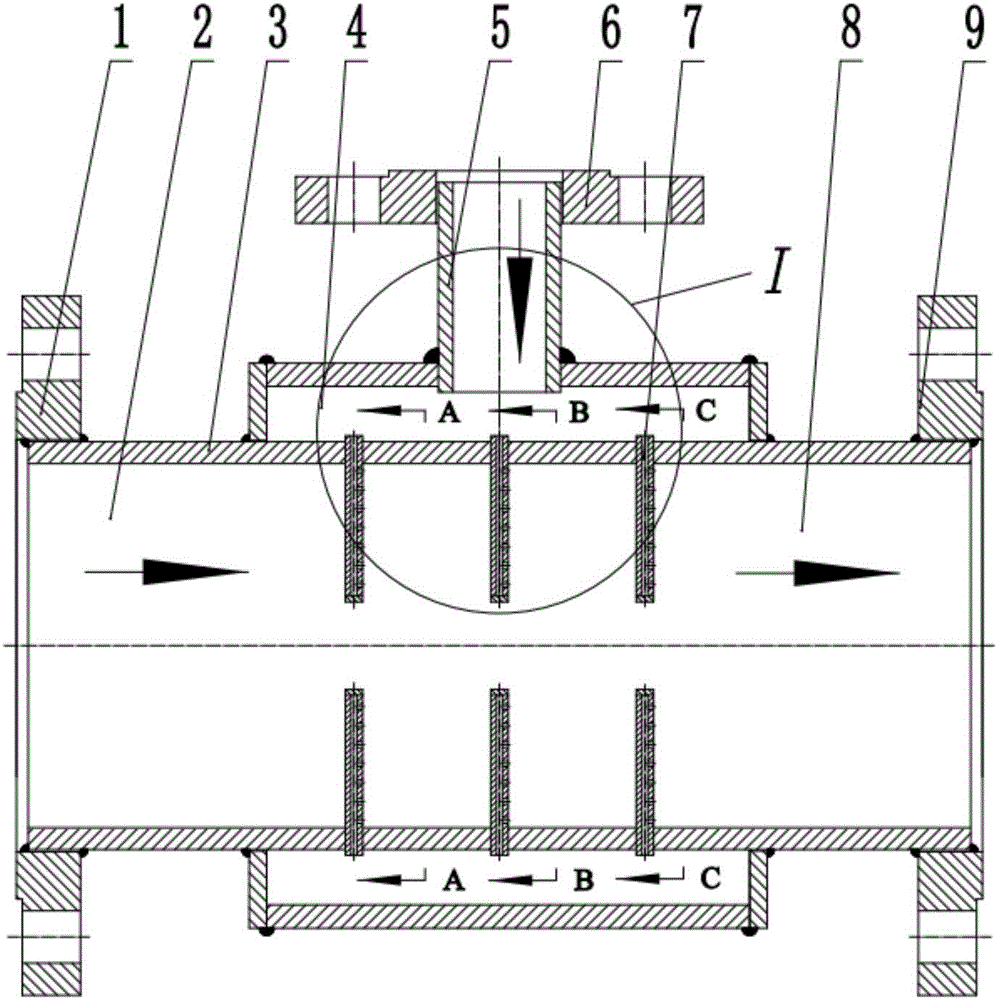

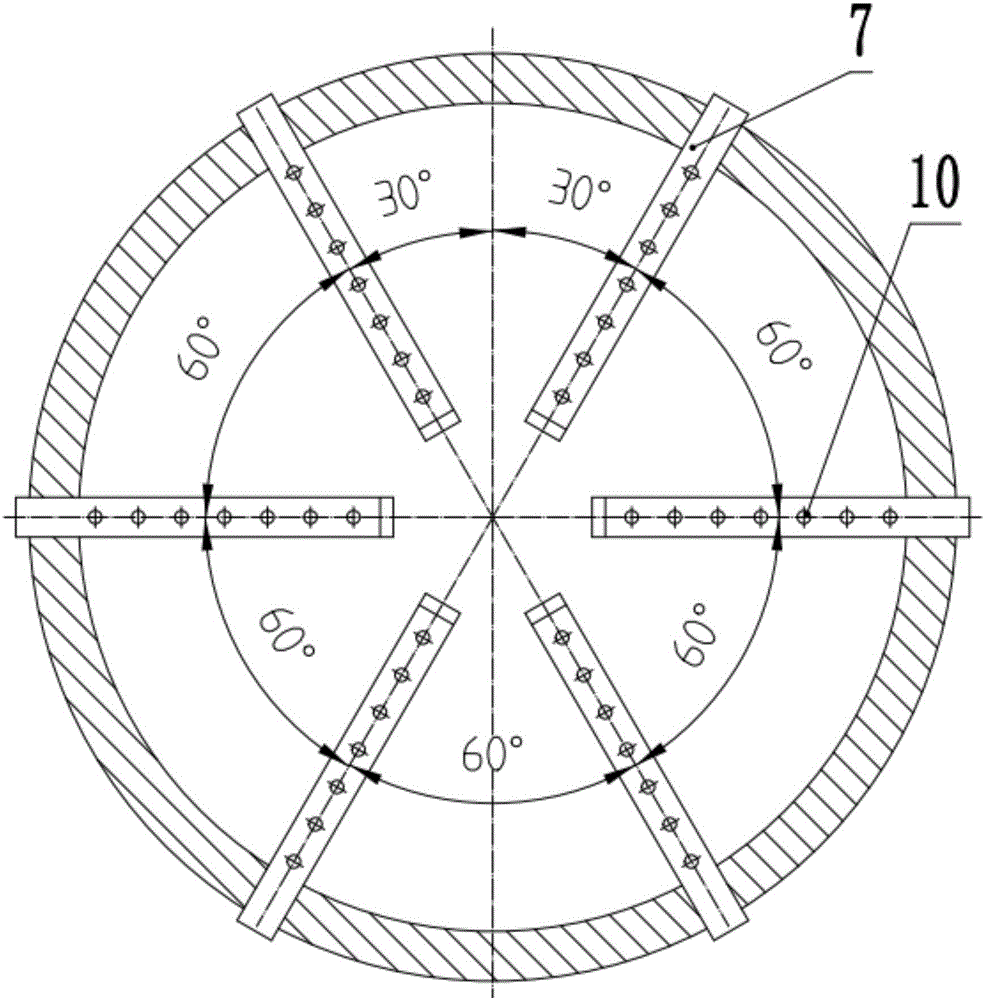

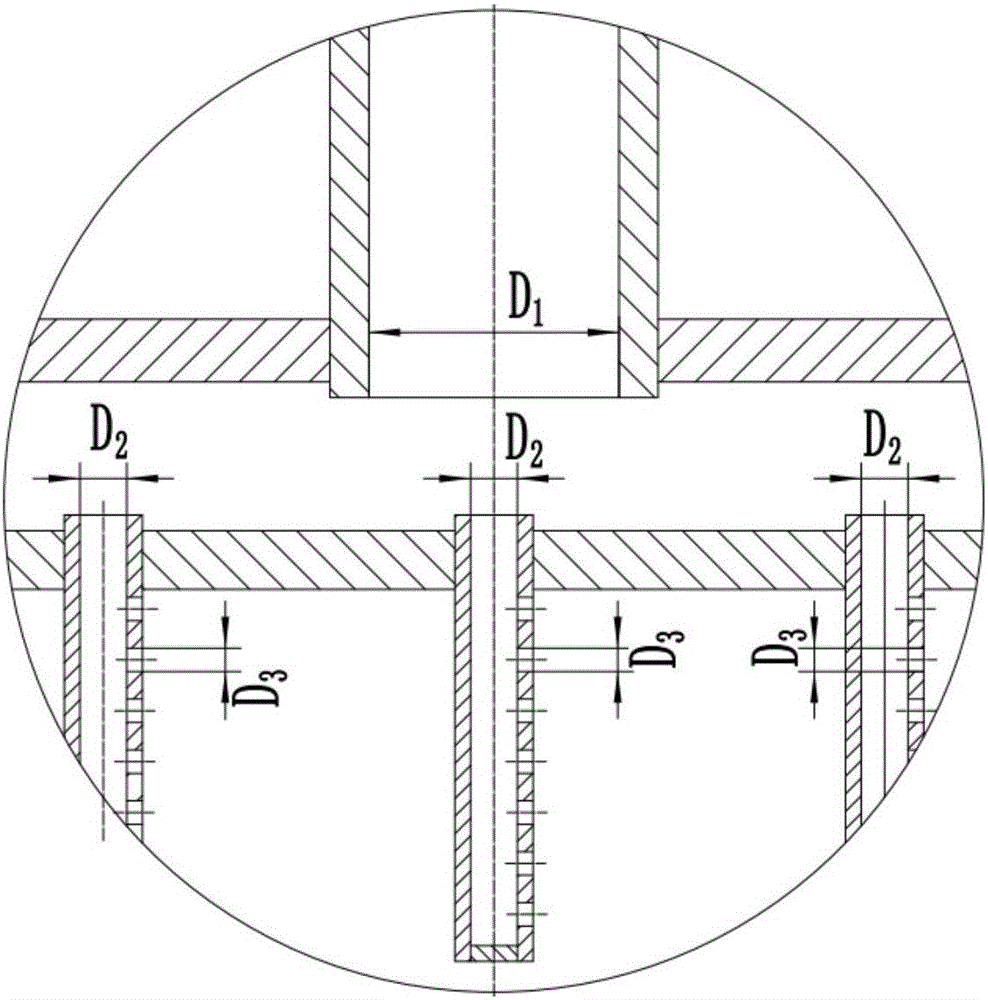

[0027] The main purpose of the present invention is to provide a gas-liquid mixing device to realize uniform mixing of gas and liquid. figure 1 Shown is an embodiment of the gas-liquid mixing device of the present invention, the gas-liquid mixing device includes a liquid delivery end 2, a liquid delivery pipeline 3, a gas gathering chamber 4, a gas delivery pipeline 5, and a gas-liquid mixing rod 7 and mixing delivery channel 8. The gas input pipeline 5 and the liquid delivery pipeline 3 are arranged at 90 degrees, the gas delivery pipeline 5 and the liquid delivery pipeline 3 are all round tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com