Model for producing high-speed unballasted railway turnout tie and method for producing turnout tie

A railway and high-speed technology, which is applied in the production of high-speed ballastless railway turnout sleeper models and the field of turnout sleeper production, can solve the problem of deformation of the end of high-speed ballastless railway turnout sleepers, and poor sealing of the end forming orifice plate, which cannot be effectively guaranteed Reinforced trusses and other problems, to achieve the effect of long service life, strong bearing capacity and fatigue resistance, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, and present embodiment is based on the premise of technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

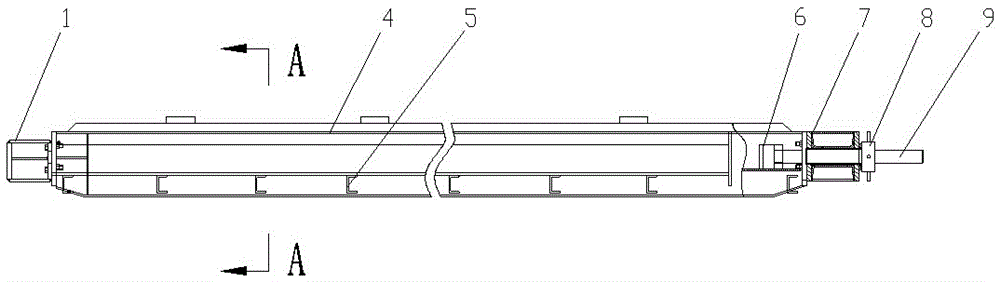

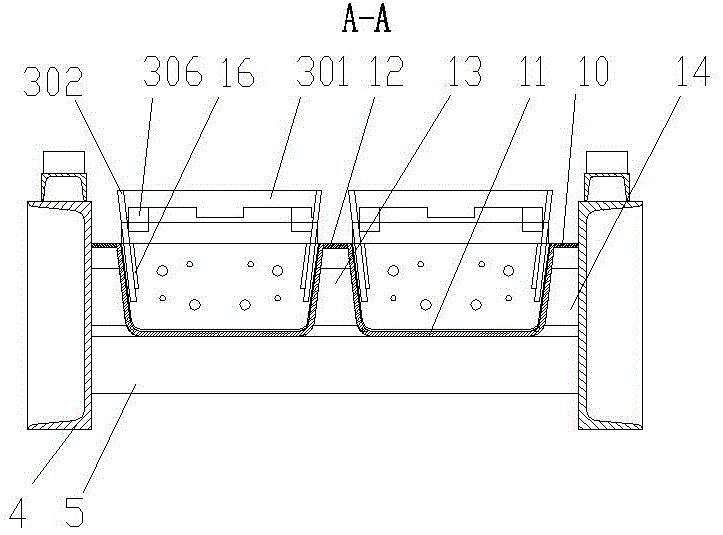

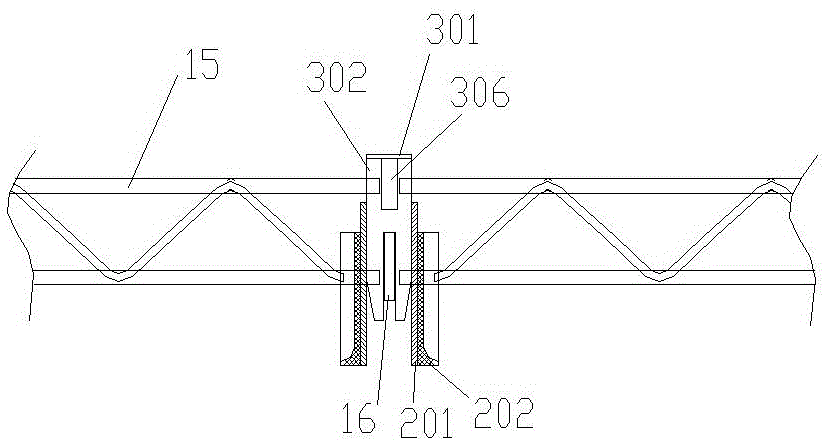

[0034] As shown in the figure, a model for producing high-speed ballastless railway turnout sleeper, the high-speed ballastless railway turnout sleeper is to put threaded steel bar a, prestressed steel wire and steel bar truss 15 into the model and tension the prestressed steel wire After pouring concrete into the model, the steel bar truss 15 includes three threaded steel bars b arranged in an isosceles triangle, and the threaded steel bar b at the bottom edge is fixedly connected with the threaded steel bar b at the top corner through corrugated steel bars. Said model comprises two side beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com