Road vehicle wheel structure and method for loading loads of wheel

A technology for road vehicles and vehicle loads, applied in vehicle components, elastic suspensions, suspensions, etc., can solve the problems of gravity decomposition and utilization of vehicle loads, lack of skills in structural mechanics, and low wheel movement efficiency, and achieve the goal of improving mechanical efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

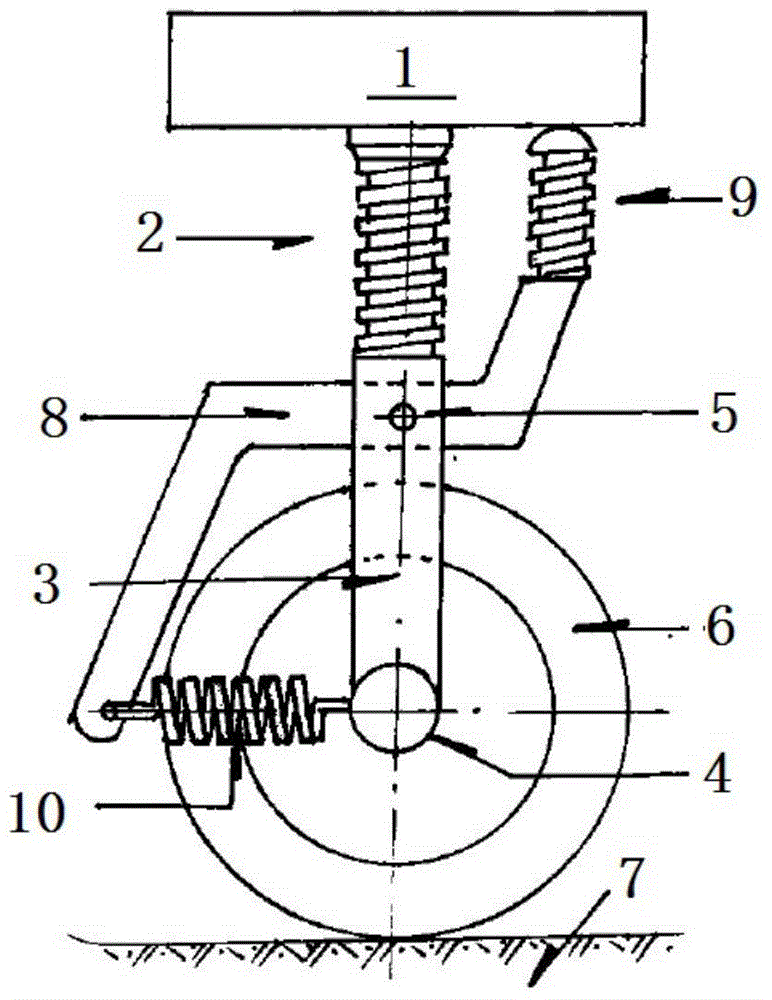

[0046] figure 1 As shown, the upper buffer connector 2 of the support member and the upper buffer connector 9 of the mechanical lever are connected to the vehicle body 1; the mechanical lever 8 is dynamically connected to the support rod 3 through the lever support point 5; the other end of the mechanical lever 8 is connected to the center of the wheel through the tension spring 10 4 is connected horizontally; the wheel 6 is connected to the support 3 through the wheel center 4, and its center is perpendicular to the road surface 7.

Embodiment 2

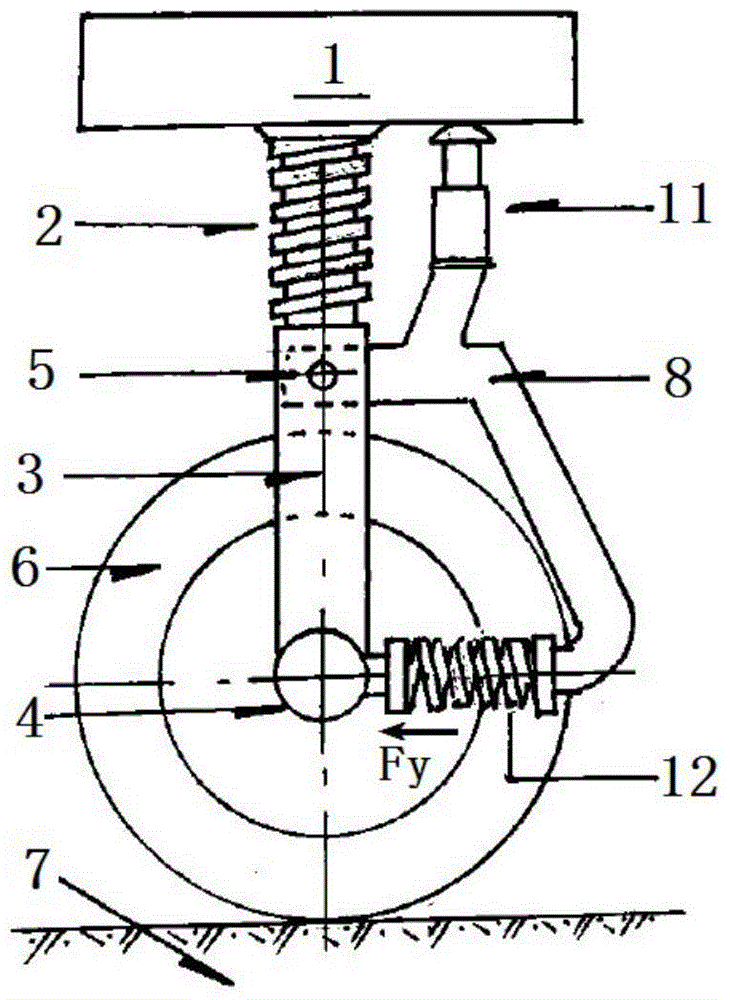

[0048] figure 2 As shown, the upper buffer connector 2 of the support rod and the upper hydraulic cylinder 11 of the mechanical lever; the mechanical lever 8 is dynamically connected with the support member 3 through the lever support point 5; the other end of the mechanical lever 8 is horizontally connected with the wheel center 4 through the compression spring 12; 6 is connected with support member 3 through wheel center 4, and its center is perpendicular to road surface 7.

Embodiment 3

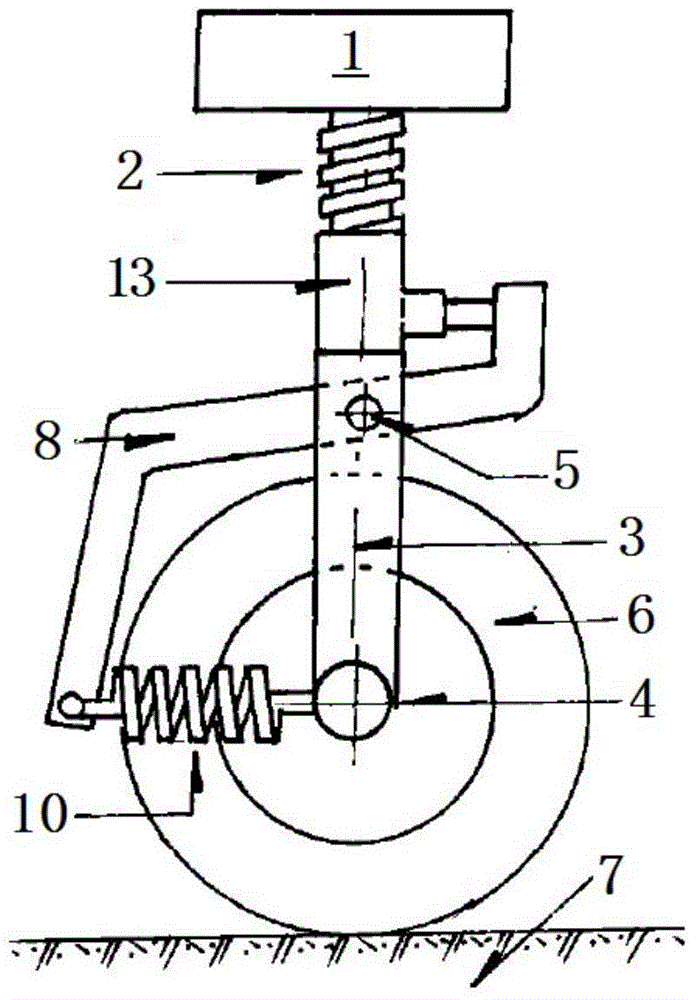

[0050] image 3 As shown, the upper buffer connector 2 of the support rod is connected with the vehicle body 1; the support member 3 is connected with the upper force buffer 13 of the mechanical lever; the mechanical lever 8 is dynamically connected with the support member 3 through the lever support point 5; the other end of the mechanical lever 8 is connected via The compression spring 12 is horizontally connected to the wheel center 4; the wheel 6 is connected to the support member 3 via the wheel center 4, and its center is perpendicular to the road surface 7.

[0051] The invention is suitable for the wheel system structures of various road vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com