Dedusting, demisting, dewatering and deicing system

A heat exchanger and gas technology, applied in the fields of defogging, deicing, waterproofing systems, and dust removal, it can solve the problems of high energy consumption, unsuitable for small or curved surfaces or mirror surfaces, failures, etc., and achieve high exhaust temperature, work better

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

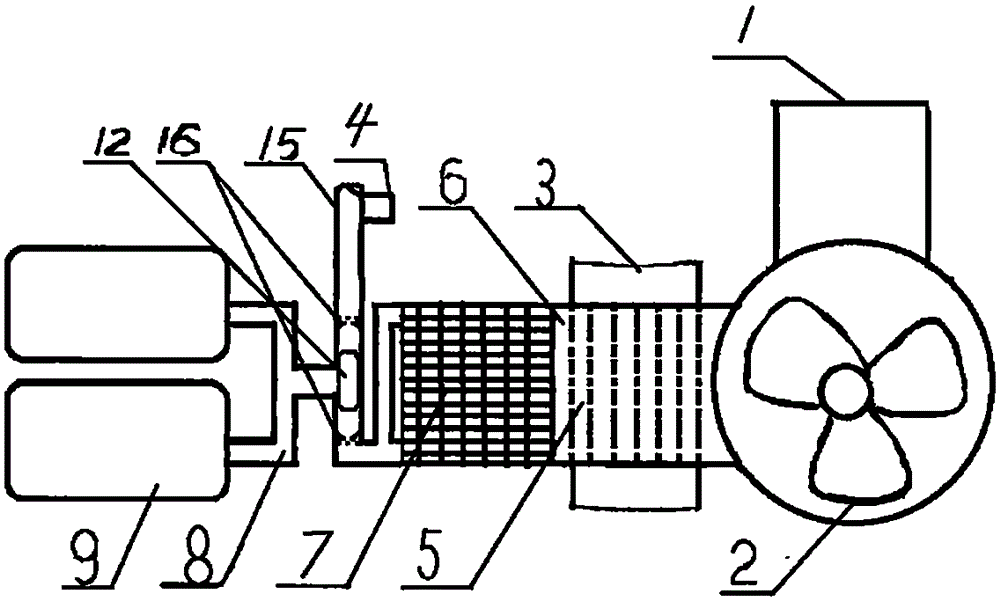

[0020] Below in conjunction with accompanying drawing and specific implementation method, the present invention will be described in further detail:

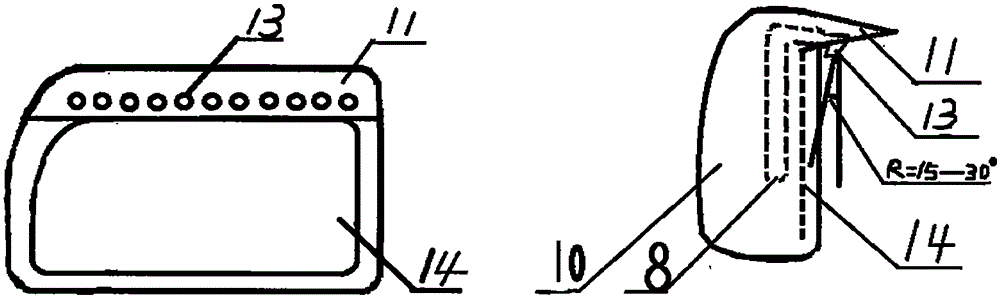

[0021] The gas is pressurized from the fan inlet 1 through the fan blade 2, and then the gas that enters through the heat exchange pipe 5 and the engine exhaust pipe inlet 3 undergoes heat exchange in the gas heat exchanger 6 and becomes heated gas, enters the gas drying filter 7 and passes through the drying filter element After the desiccant is dried and filtered, it becomes heated, dry and clean gas, which enters the surface and mirror gas into the pipe 8 through the two-way pressure difference switching valve 12, and dedusts, defogs, dehumidifies and deices the surface and mirror 14 through the nozzle 13 . When other gas enters the air inlet pipe 15, the pressure sensor 4 senses the pressure and cuts off the power supply of the fan to stop the fan, and the pressure of other gas pushes the two-way pressure difference switchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com