Mountainous area small-load sleeve type foundation structure

A technology of tubular foundations and load sleeves, which is applied in the field of small-load sleeved foundation structures in mountainous areas, to achieve the effect of improving pullout resistance and anti-overturning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

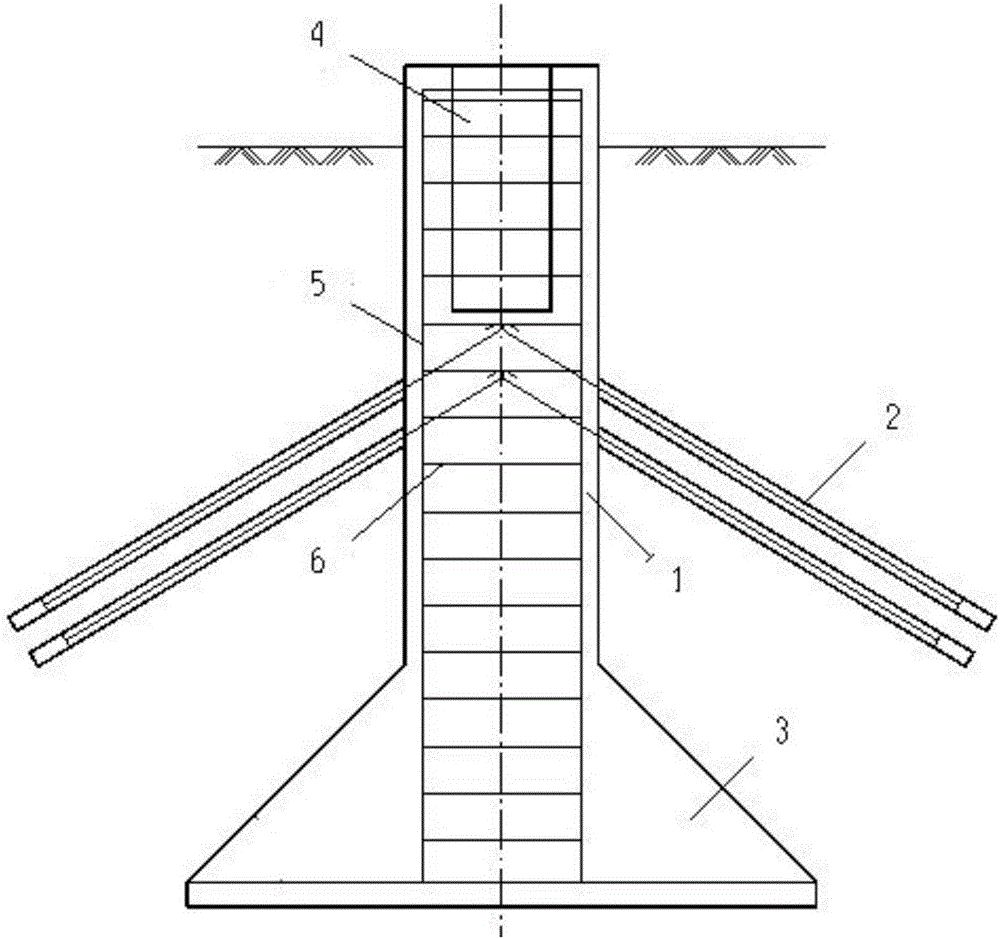

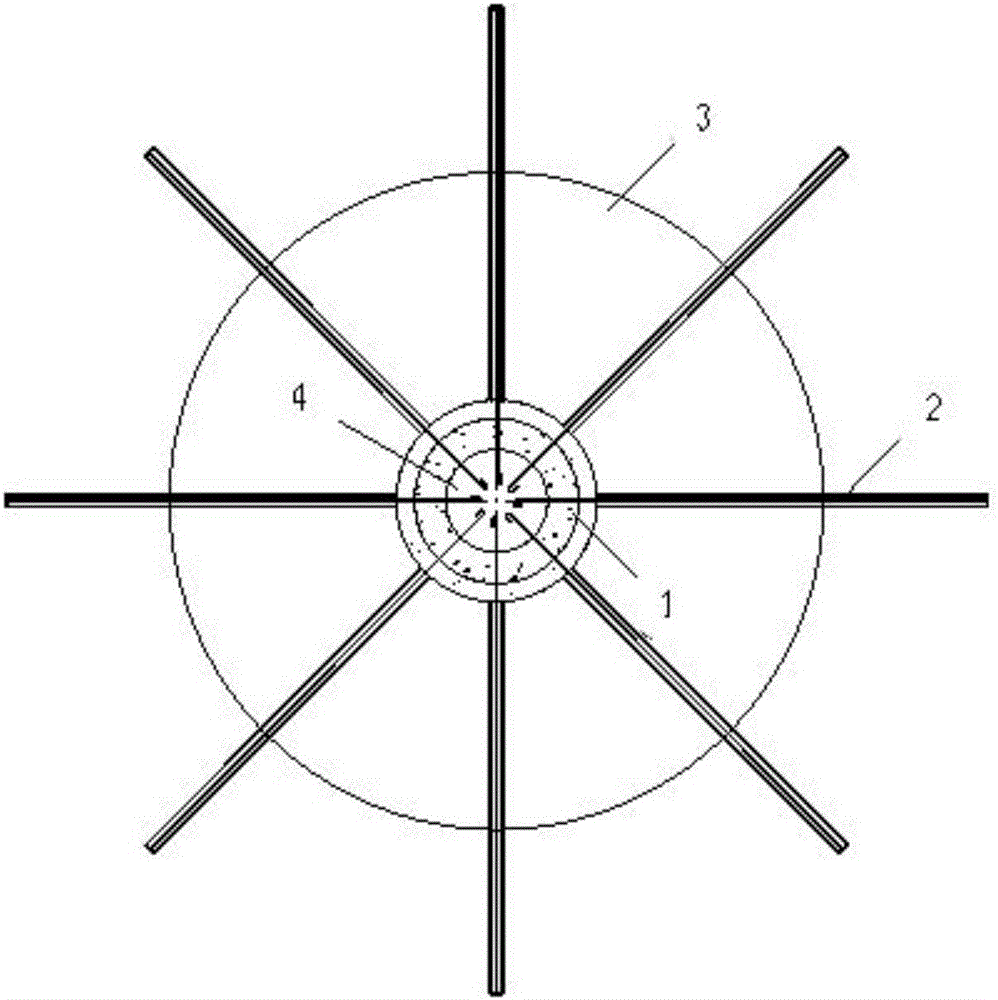

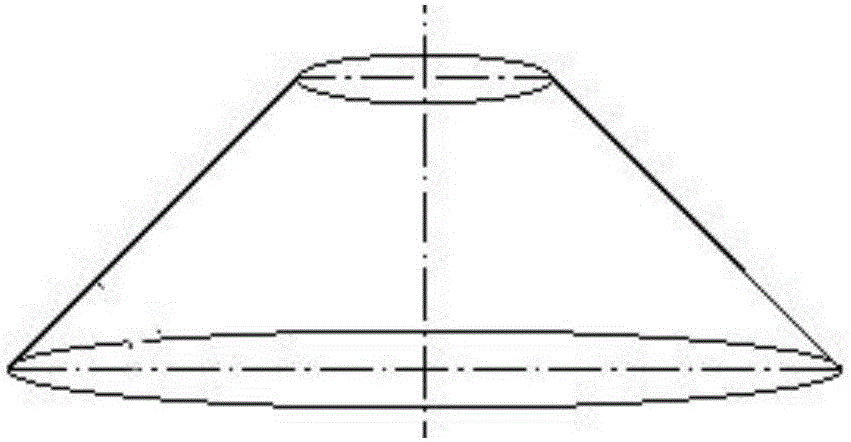

[0016] like Figure 1-Figure 3 Shown is a small-load sleeve-type foundation structure in mountainous areas, including a sleeve column body 1 embedded below the ground and a lower expansion bottom 3 integrated with the sleeve column body. The lower expansion bottom is located at the bottom of the sleeve column body The lower end, the overall orthographic projection surface of the bottom expansion bottom is a circular structure, the upper end diameter of the bottom expansion bottom is smaller than the bottom diameter, and the sleeve column body is provided with a hole 4 for power supply rod insertion, and the hole groove is a blind hole. A plurality of oblique anchor rods 2 are distributed in a circular array around the column body, and the oblique anchor rods have a structure of upper and lower layers. Each layer has at least three, and the angle between the inclined anchor rod and the column body is any value between 30-60 degrees. One end of the inclined anchor rod is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com