Assembling-type beam-column hinged node and assembling mode thereof

A prefabricated, beam-column technology, applied in the direction of architecture, building structure, etc., can solve the problems of complex beam-column joint connection structure, no obvious advantages and progress, and inconvenient wet operation, so as to shorten the assembly construction period and have strong versatility , Reduce the effect of dirty construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

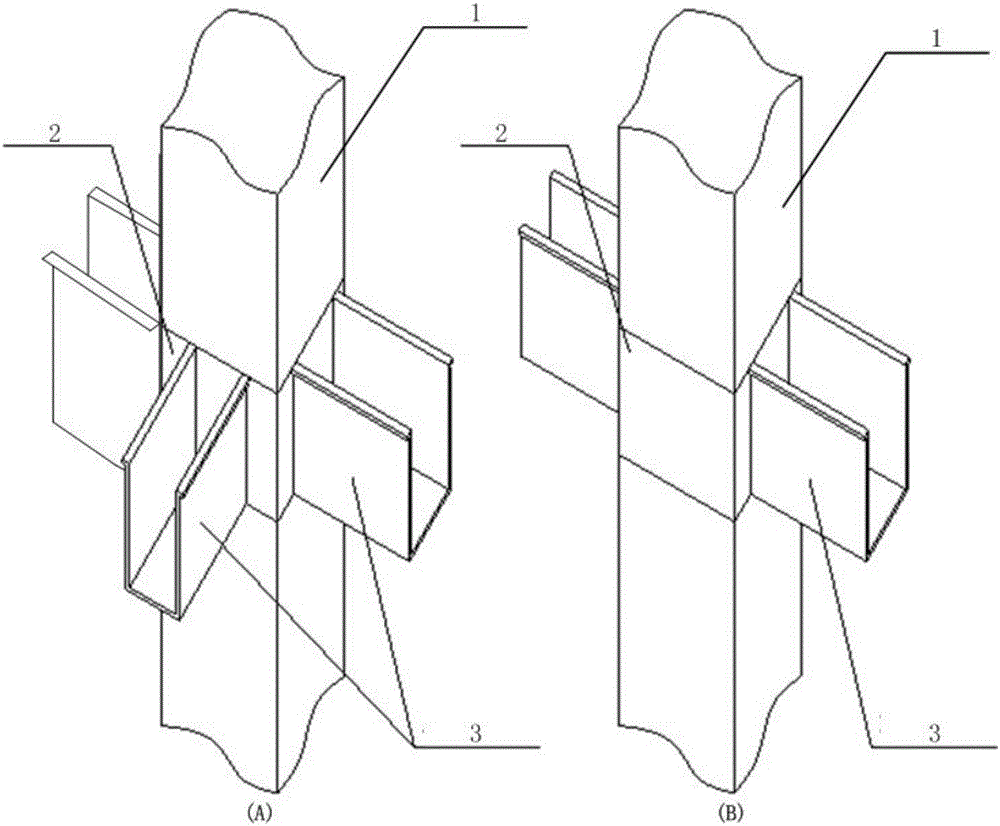

[0036] Such as figure 1 As shown in (B), the prefabricated beam-column joints, including figure 1 As shown in (B), the prefabricated beam-column hinge joint includes prefabricated column 1 and prefabricated beam 4; prefabricated column 1 is provided with hoop 2, and hoop 2 is provided with two U-shaped connecting plates 3; two U-shaped The shaped connecting plate 3 makes the nodes of the beam-column connection form a triangular stable structure, which increases the stability of the beam-column connection.

[0037] The prefabricated column 1 is a square column, and the prefabricated column 1 is installed with the ferrule 2 and two U-shaped connecting plates 2 after prefabrication.

[0038] The U-shaped connecting plate 3 is fixedly connected with the outer surface of the ferrule 2 where it is located.

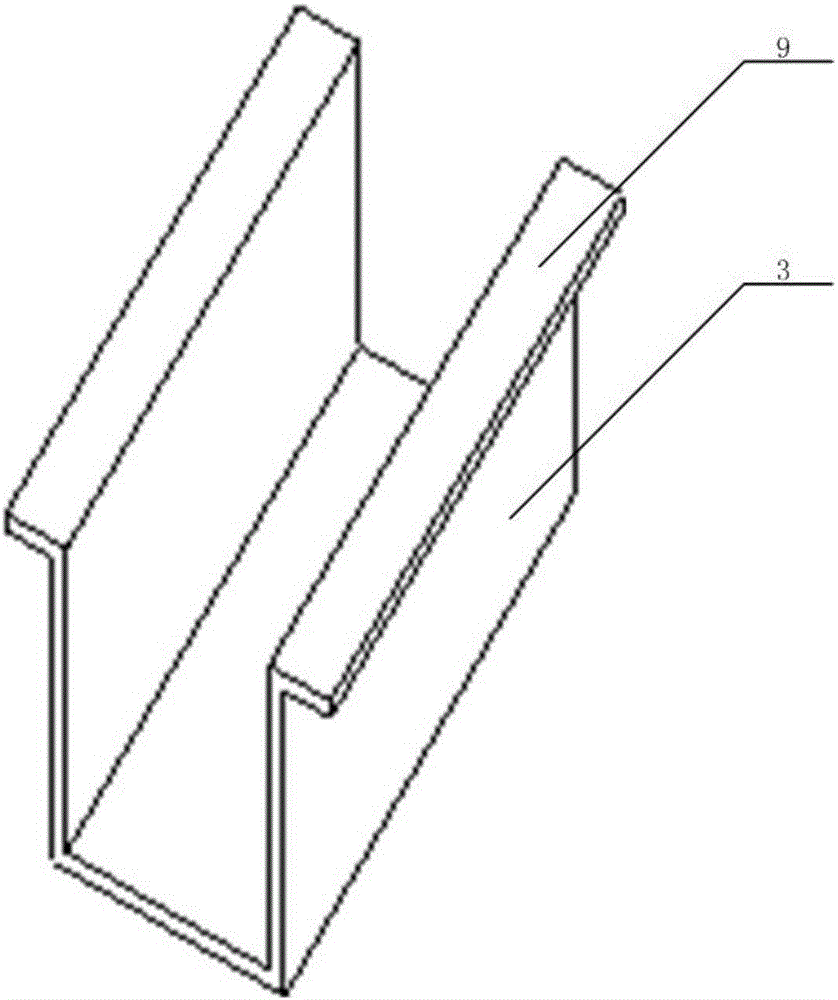

[0039] Such as figure 2 As shown, the U-shaped connecting plate 3 is provided with a U-shaped connecting plate edge 9 .

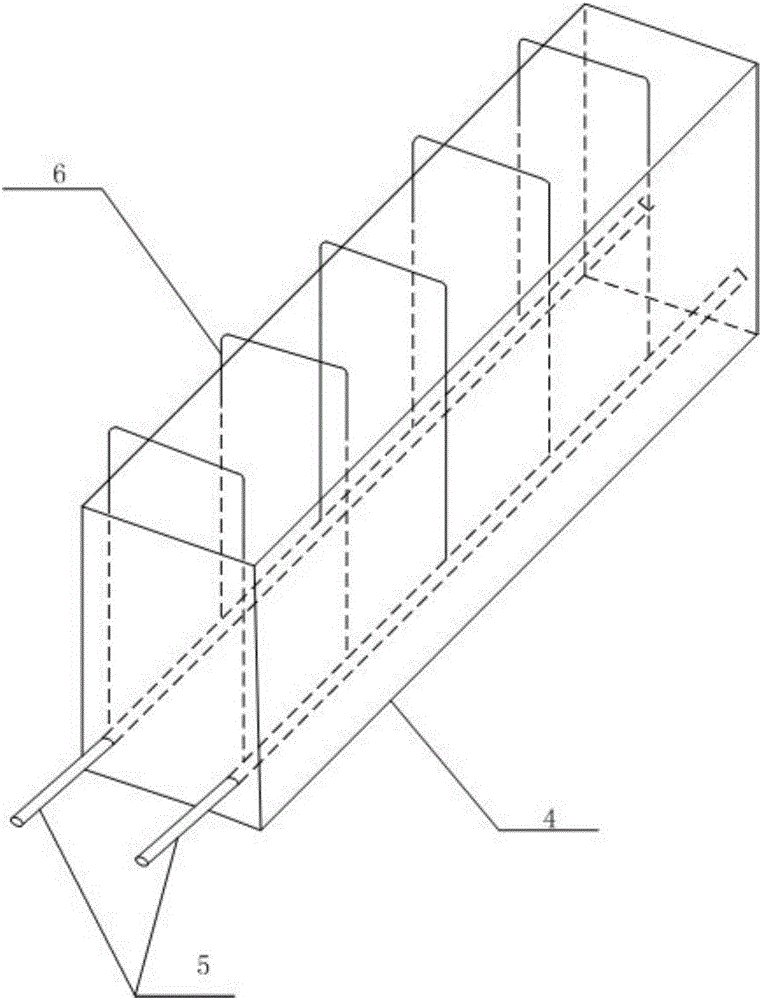

[0040] Such as image 3 As shown, the prefabricat...

Embodiment 2

[0053] Such as figure 1 As shown in (A), the prefabricated beam-column joints, including figure 1 As shown in (B), the prefabricated beam-column hinge joint includes prefabricated column 1 and prefabricated beam 4; prefabricated column 1 is provided with hoop 2, and hoop 2 is provided with three U-shaped connecting plates 3; three U-shaped The connecting plate 3 can be used for the beam-to-column connection of the edge part of the building body.

[0054] The prefabricated column 1 is a square column, and the prefabricated column 1 is installed with the ferrule 2 and three U-shaped connecting plates 2 after prefabrication.

[0055]The U-shaped connecting plate 3 passes through the hoop 2 where it is located, and one end thereof is located inside the prefabricated column 1 .

[0056] Such as figure 2 As shown, the U-shaped connecting plate 3 is provided with a U-shaped connecting plate edge 9 .

[0057] Such as image 3 As shown, the prefabricated beam 4 includes a beam bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com