Fabricated rigid joint beam-column structure

A beam-column structure, prefabricated technology, applied in building structure, construction and other directions, can solve the problems of dirty construction site, prone to honeycomb pitted surface, complex steel structure, etc. Enhanced performance and reduced wet work effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

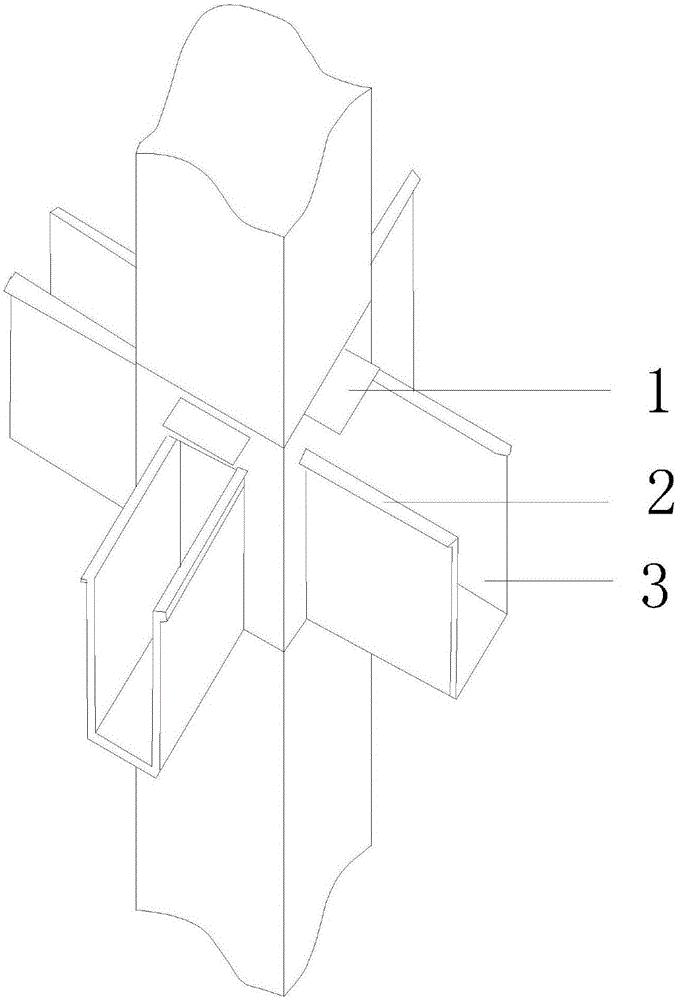

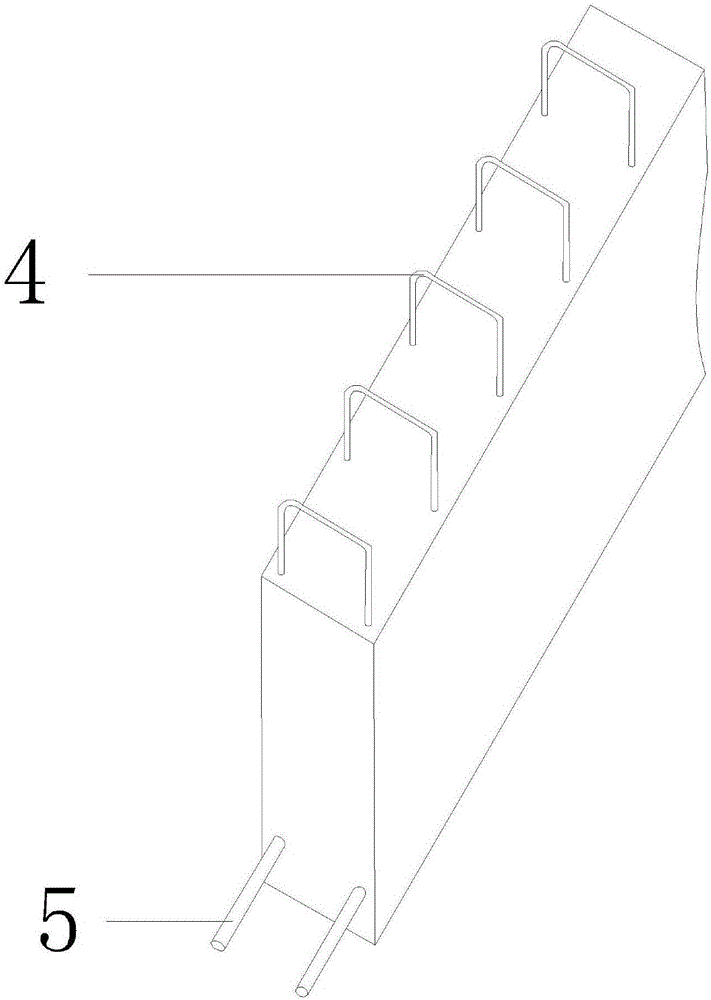

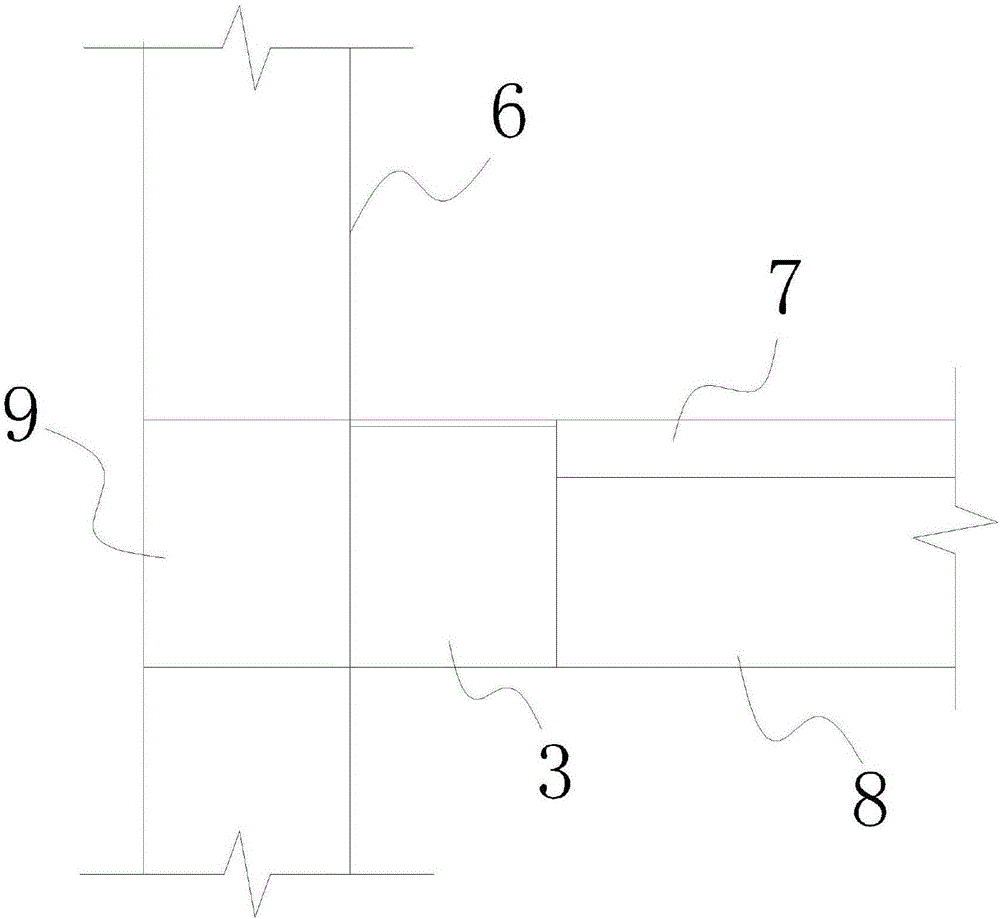

[0027] Such as Figure 1~4 An assembled rigid-joint beam-column structure is shown, including: prefabricated columns 6, prefabricated beams 8, prefabricated beams 8 are provided with inner stirrups 4, prefabricated columns 6 are provided with several connecting grooves 3 and several connecting plates 1 , the prefabricated column 6 is a square body, and at least one side is provided with a connecting groove 3 and a connecting plate 1. In this embodiment, a connecting groove 3 and two connecting plates 1 are provided on each side of the prefabricated column 6, but For your convenience, Figure 4 Only one connection structure is shown, wherein the connection groove 3 is mainly composed of three splicing plates, the opening is located at the top of the connection groove 3, and there is an opening at one end. In order to facilitate the placement of the prefabricated beam 8, the cross section of the connection groove 3 is similar to " U" shape, but the bottom corners are square rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com