Thread guiding device

A wire guide device and wire guide technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

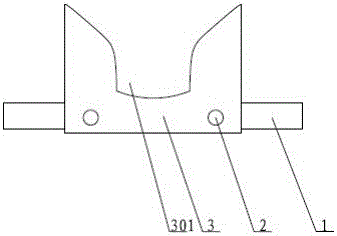

[0009] Below in conjunction with accompanying drawing, the present invention will be further described:

[0010] As shown in the figure, a wire guide device includes a guide wire rod holder 1, on which a guide wire rod 3 is fixed by a set screw 2, the guide wire rod 3 has a U-shaped structure, and the guide wire rod 3 is integrally formed by The wear-resistant alumina ceramic material is used, or the inner wall of the U-shaped mouth 301 of the guide wire rod 3 is provided with an alumina ceramic wear-resistant layer. In order to achieve a better effect, the U-shaped opening 301 of the guide wire rod 3 is set to 5-10cm.

[0011] After adopting the above-mentioned structure, the guide wire rod can not only reduce disordered threads, improve the uniformity of falling barrel, but also effectively reduce loss.

[0012] What has been described above and shown in the drawings are only preferred embodiments of the present invention. It should be pointed out that those skilled in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com