Low-impact and high -bearing-capacity pyrotechnics release bolt

A technology of unlocking bolts and high load-bearing, applied in the direction of screws, threaded fasteners, connectors with special improvement in tensile load, etc. The effect of reducing pyrotechnic shock and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

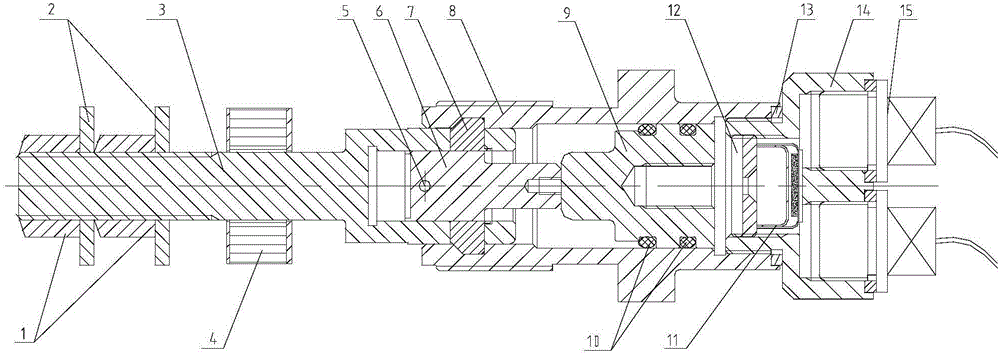

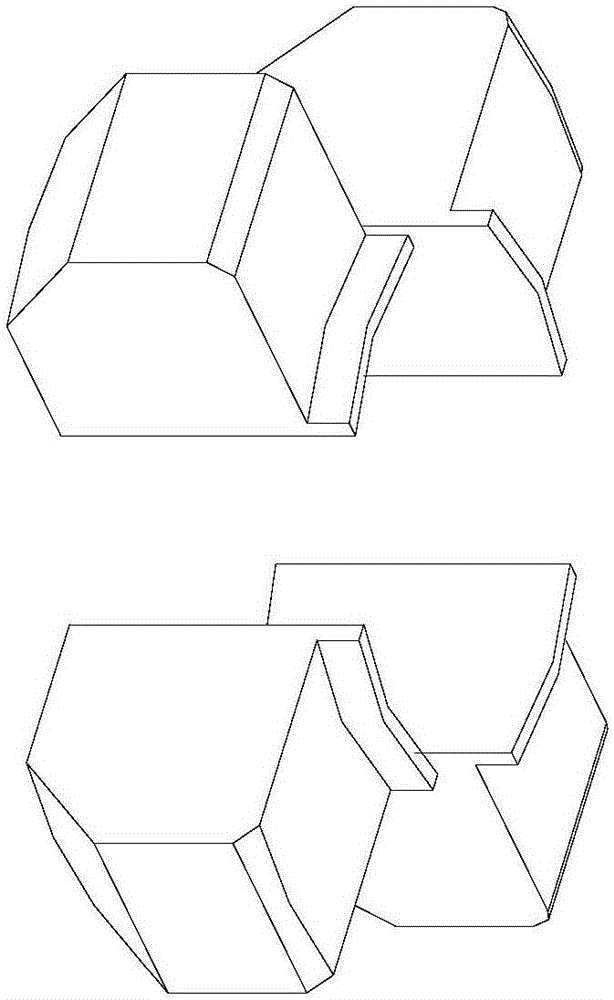

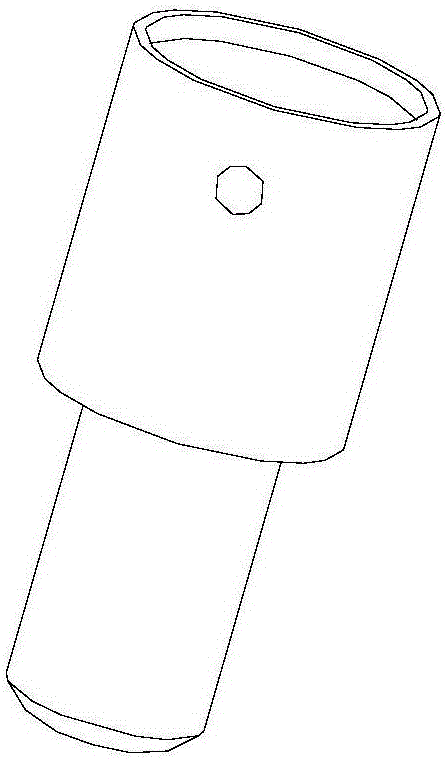

[0023] Such as figure 1 As shown, a low-impact high-load pyrotechnic unlocking bolt consists of a nut 1, a gasket 2, an inner cylinder 3, a honeycomb part 4, a shear pin 5, a slide rod 6, a wedge 7, an outer cylinder 8, a piston 9, O-shaped rubber ring 10, medicine box 11, medicine retaining plate 12, aluminum washer 13, medicine case 14, igniter 15 form. One end of the inner cylinder 3 is a cylinder and passes through the honeycomb part 4. The honeycomb part 4 is installed at the bottom of the outer separation body. The other end of the inner cylinder 3 is cylindrical and installed in the outer cylinder 8; the sliding rod 6 is installed at the cylindrical end of the inner cylinder 3 Inside, one end is fixedly connected to the side wall of the inner cylinder 3 through the shear pin 5 inserted in the radial direction; the wedge 7 passes through the side wall of the inner cylinder 3 and is inserted into the inner wall of the outer cylinder 8, and is located between the slide bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com