A lens propulsion actuator

A technology for actuators and lenses, applied in the field of electric servo systems, can solve the problems of no technology disclosure in Solution 3, and achieve the effects of compact structure, convenient assembly, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

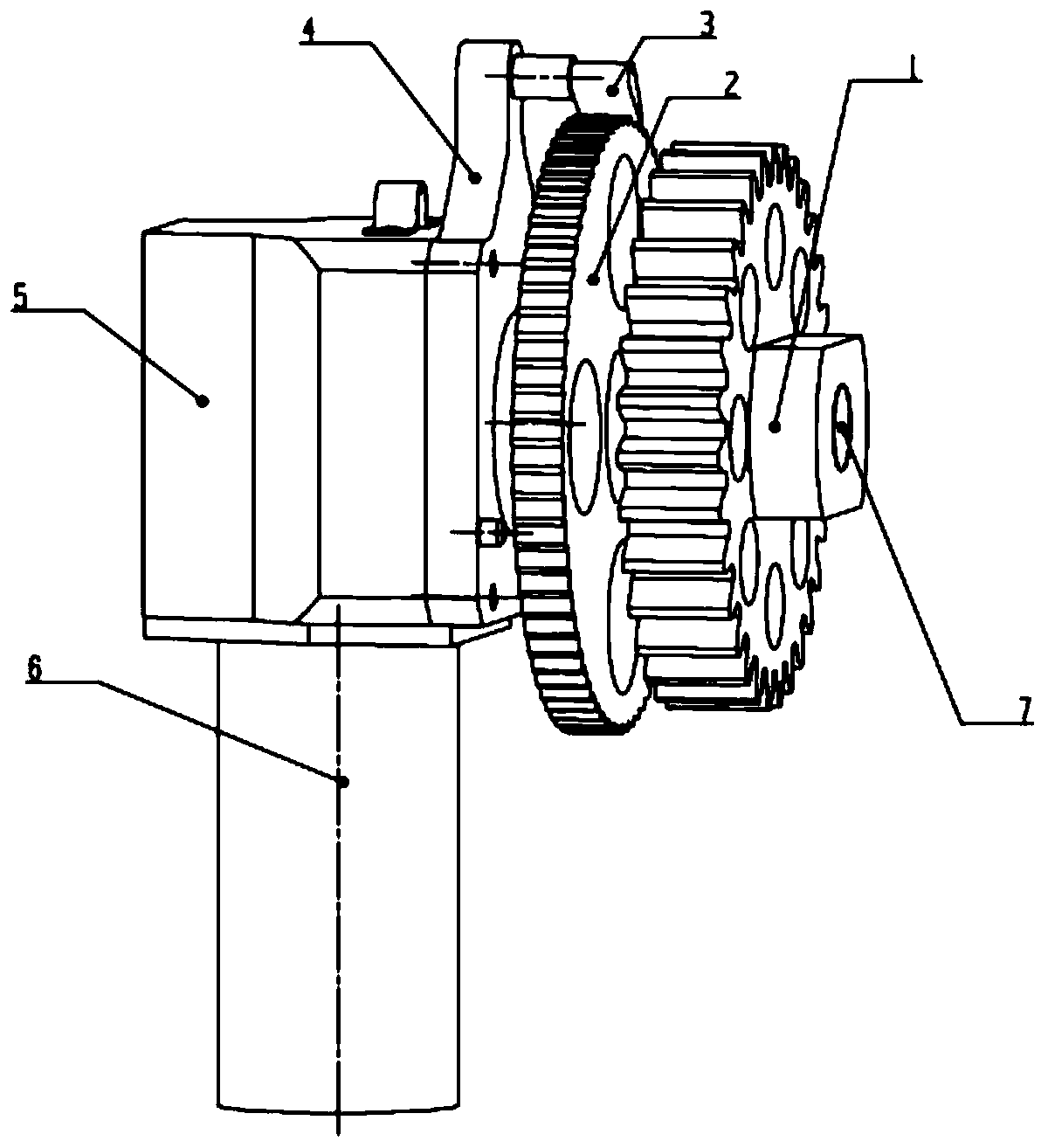

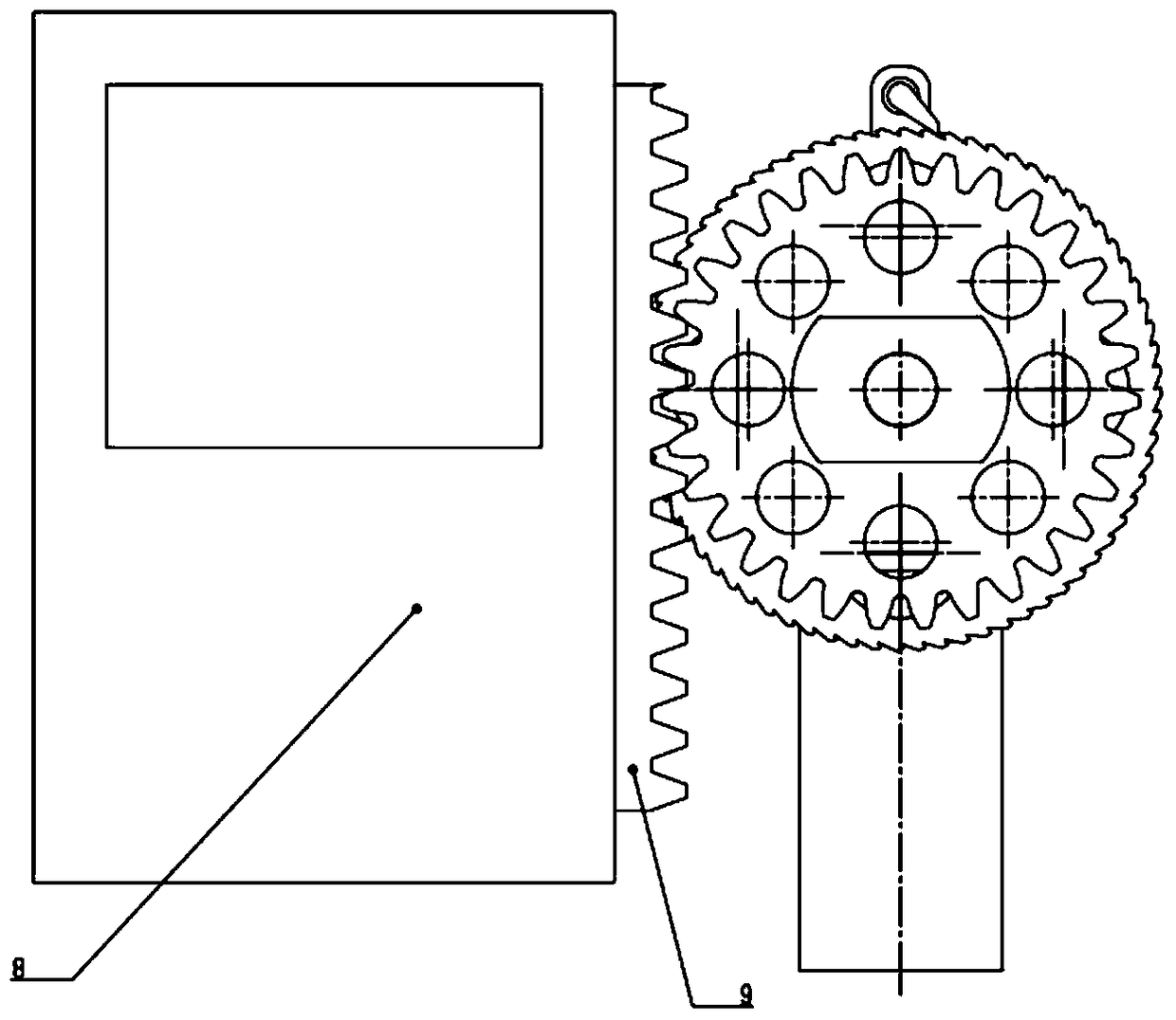

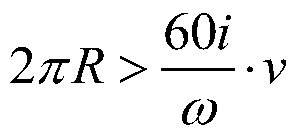

[0025] A lens propulsion actuator of the present invention consists of a transmission gear 1, a ratchet 2, a pawl 3, an installation end cover 4, a harmonic reducer housing 5, a servo motor 6, a harmonic reducer output shaft 7, a lens installation cabin 8, Gear rack 9 etc. are formed. The harmonic reducer is used as the reduction mechanism, the servo motor 6 is installed on the harmonic reducer housing 5, and the installation end cover 4 is installed on one side of the harmonic reducer housing 5, and the installation end cover 4 and the harmonic reducer housing The body 5 is fastened by screws; a protruding structure is set above the mounting end cover 4, and the pawl 3 is installed on the protruding structure; it is installed sequentially between the mounting end cover 4 and the outermost end of the output shaft 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com