Rack and bundling machine

A rack and front rack technology, applied to agricultural machinery and implements, packaging, application, etc., can solve problems such as potential safety hazards, and achieve the effect of eliminating potential safety hazards and reducing power sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

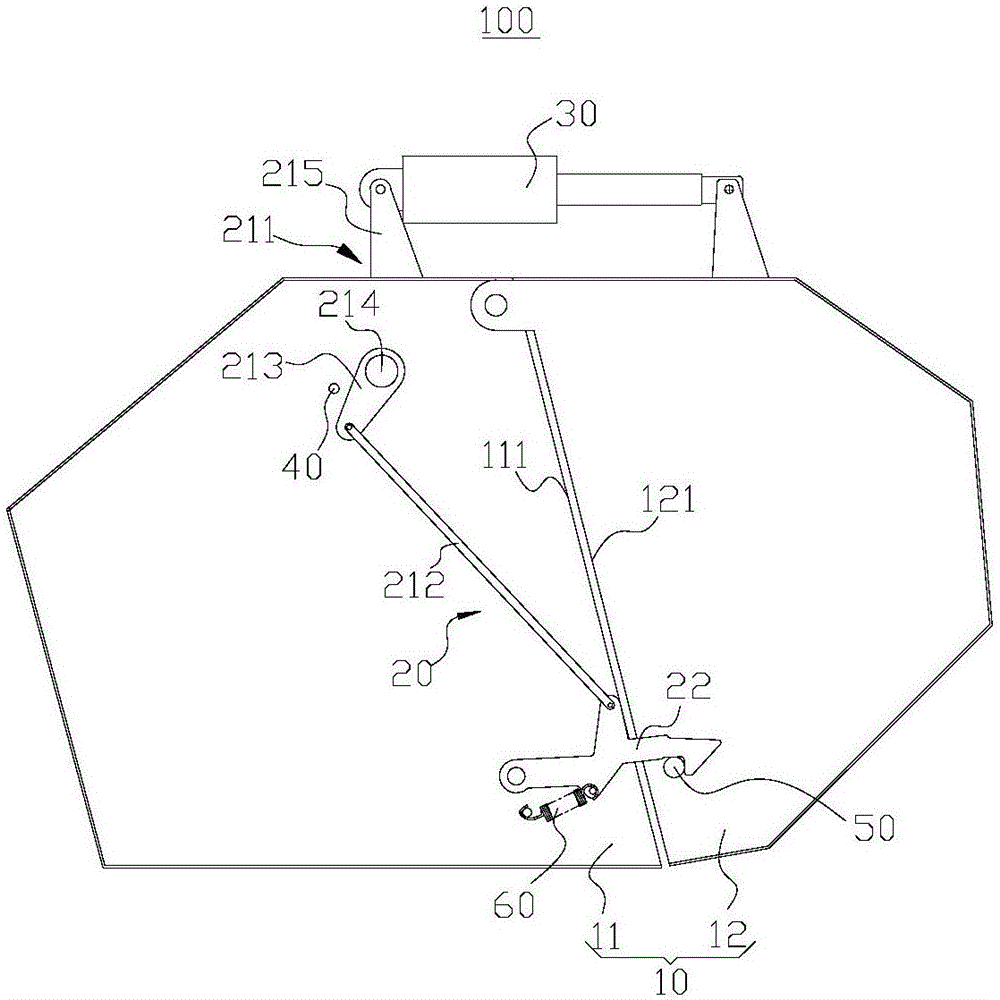

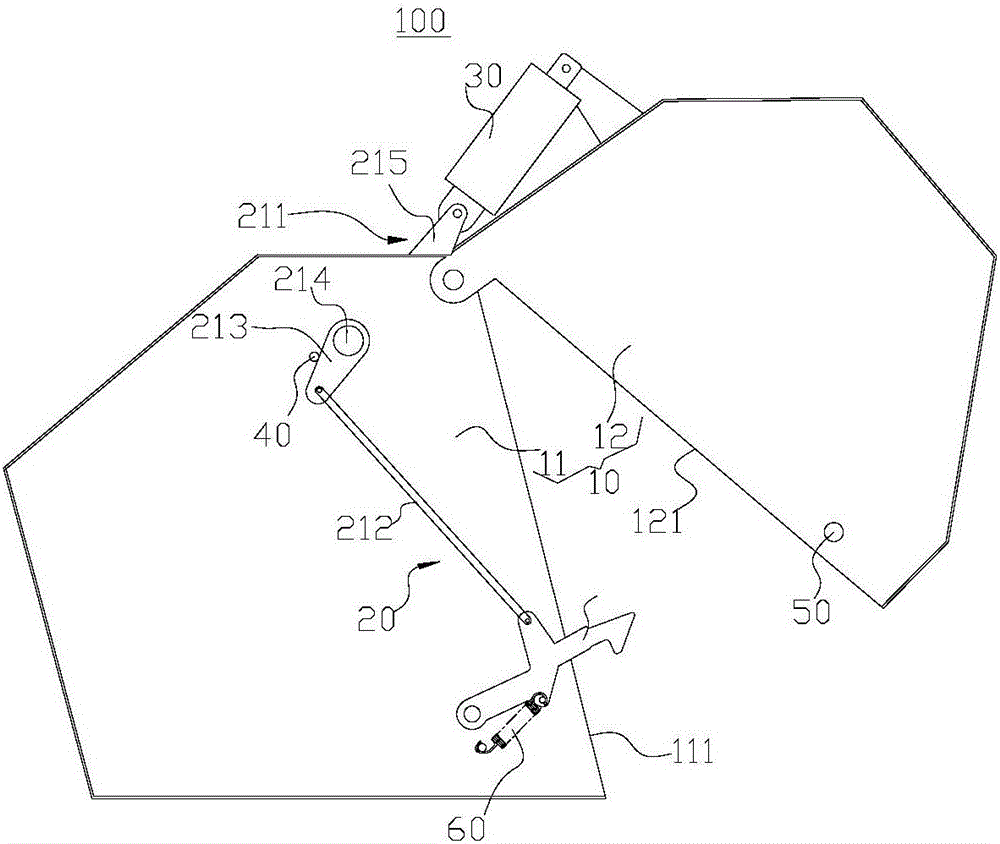

[0051] Such as figure 1 , figure 2 As shown, this embodiment provides a frame 100 , including a frame body 10 , a locking mechanism 20 and a hydraulic cylinder 30 .

[0052] The frame body 10 includes a front frame 11 and a rear frame 12, the top of the front frame 11 near the rear frame 12 is rotatably connected with the top of the rear frame 12 near the front frame 11 side, and the hydraulic cylinder 30 is used for The rear frame 12 is driven to rotate relative to the front frame 11 .

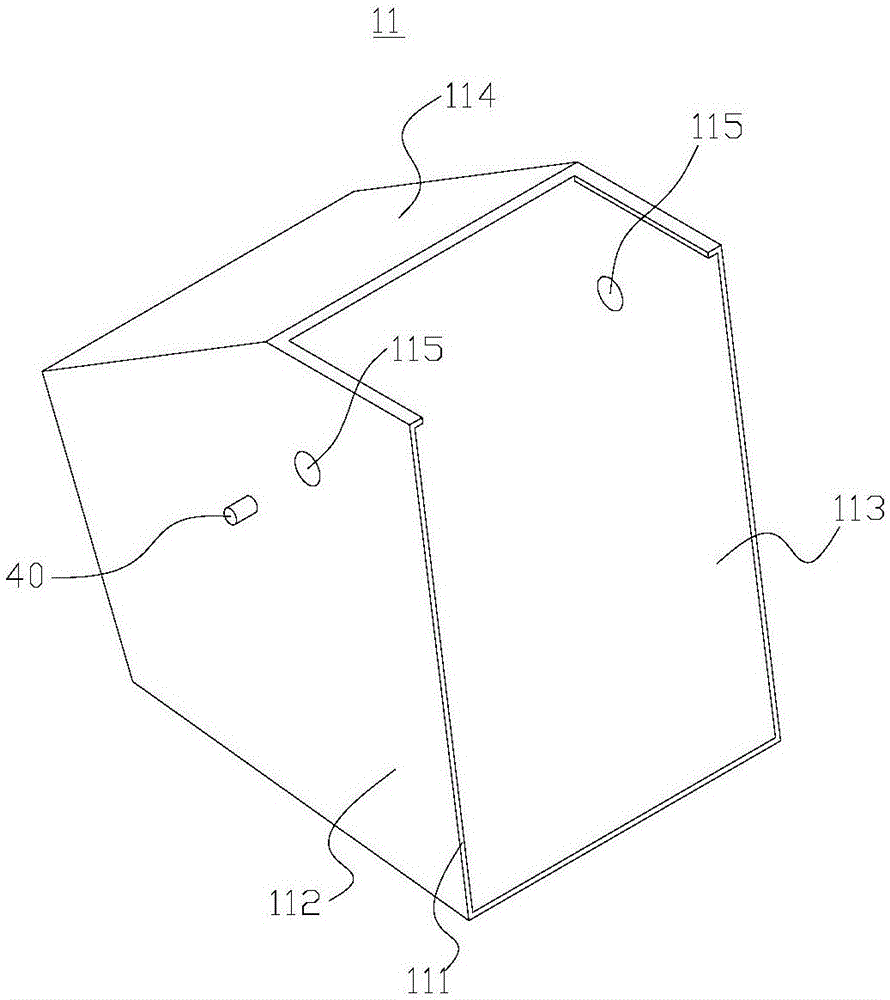

[0053] In this embodiment, specifically, as image 3 As shown, the front frame 11 is roughly a pentagonal prism structure, which is composed of two parallel pentagonal side plates and three connected peripheral plates 114 and a hollow structure with an opening on one side. The inclined first bonding surface 111 . Wherein, the two parallel pentagonal side plates are respectively the first side plate 112 and the second side plate 113 , and the first side plate 112 and the second side plate...

Embodiment 2

[0067] The rack 100 provided by the embodiment of the present invention has the same realization principle and technical effects as the aforementioned method embodiments. For brief description, for the parts not mentioned in the device embodiments, reference may be made to the corresponding methods in the aforementioned method embodiments. content.

[0068] In the above embodiment, the hydraulic cylinder 30 is not only the power source for the rotation of the rear frame 12, but also the power source for the action of the locking mechanism 20. During the process of the frame body 10 from the open state to the closed state, the locking mechanism may appear. 20 moves first and then the frame 12 rotates, which may lead to the phenomenon that the execution part 22 cannot cooperate with the locking part 50 .

[0069] For this reason, in this embodiment, as Figure 9 , Figure 10 As shown, further improvements are made to the limiting member 40 and the first connecting portion 213 ...

Embodiment 3

[0079] Such as Figure 15 As shown, the present embodiment provides a strapping machine 200, which includes a pick-up device 201, a strapping device 202, a transmission device 203 and the frame 100 in the above embodiment, and the strapping device 202 is located at the front of the frame 100 Inside the frame 11 , the pick-up device 201 is arranged on the lower side of the front frame 11 , and the front side of the front frame 11 is provided with a pull rod 205 .

[0080] The transmission device 203 is a chain, and the front frame 11 and the rear frame 12 are provided with a plurality of circumferentially distributed rollers 204, and the chain is used to drive all the rollers 204 to rotate.

[0081] During operation, the grass strips on the ground are picked up by the pick-up device 201 and sent into the frame 100. Under the action of the drum 204, the grass strips are rotated and gradually piled up, and finally bundled into bales by the rope binding device 202. During the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com