A kind of preparation method of quaternary ammonium salt/oxide modified biohybrid material

A bio-hybridization and oxide technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of toxic by-products, serious secondary pollution, complex synthesis process, etc., and achieve high adsorption selectivity , the processing capacity is improved, and the raw materials are environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Mix 3 g of wheat straw particles with 50 mL of a mixed solvent (methanol and 5% NaOH aqueous solution at a volume ratio of 1:1), and then program the temperature to 50 °C. Then 20mL of 3-chloro-2-hydroxypropyltrimethylammonium chloride (CTA) was evenly added dropwise at a rate of 5mL / min into the mixture, and stirred at 50°C for 1 hour. After filtration, the product was washed with water until neutral, and dried in vacuum at 30°C for 4 hours to obtain an anionic bio-exchanger modified with quaternary ammonium salt;

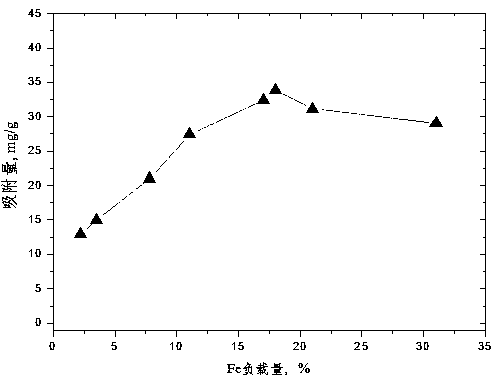

[0029] (2) Weigh 3g of the above bio-exchanger and add 10g FeCl 3 ·6H 2 O and 35mL HCl (0.1mol / L) mixed solution, stirred at 25°C for 2 hours. The material was filtered out with a strainer and added to 50mL NaOH (5wt%) solution, stirred and reacted at 25°C for 2 hours. After the completion, the product was washed with water until neutral, then washed with 5wt% NaCl solution and deionized water, and dried in vacuum at 25°C for 6 hours to obtain a quat...

Embodiment 2

[0032](1) Mix 7 g of cassava stalk particles with 50 mL of a mixed solvent (isopropanol and 10% NaOH aqueous solution at a volume ratio of 3:1), and then program the temperature to 60 °C. Then 35 mL of 3-chloro-2-hydroxypropyltrimethylammonium chloride (CTA) was evenly added dropwise at a rate of 10 mL / min into the mixture, and stirred at 60°C for 2 hours. After filtration, the product was washed with water until neutral, and dried in vacuum at 40°C for 6 hours to obtain an anionic bio-exchanger modified with quaternary ammonium salt;

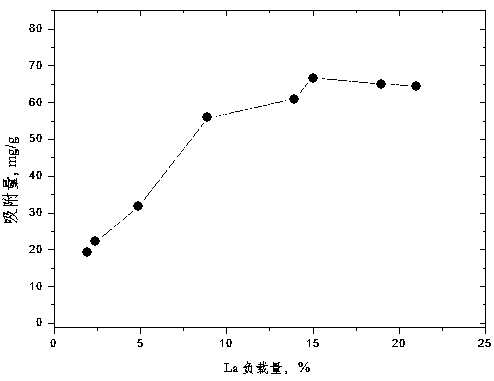

[0033] (2) Weigh 5g of the above bio-exchanger and add 20g LaCl 3 ·6H 2 O and 60mL HCl (0.3mol / L) mixed solution, stirred at 40°C for 3 hours. The material was filtered out with a strainer and added to 80mL NaOH (10wt%) solution, stirred and reacted at 40°C for 4 hours. After the end, the product was washed with water until neutral, then washed with 8wt% NaCl solution and deionized water, and dried in vacuum at 40°C for 6 hours to obtain a q...

Embodiment 3

[0036] (1) Mix 11 g of cotton stalk particles with 110 mL of a mixed solvent (ethanol and 15% NaOH aqueous solution at a volume ratio of 5:1), and then program the temperature to 70 °C. Then 60 mL of 3-chloro-2-hydroxypropyltrimethylammonium chloride (CTA) was evenly added dropwise to the mixture at a rate of 20 mL / min, and stirred at 70°C for 4 hours. After filtration, the product was washed with water until neutral, and dried in vacuum at 50°C for 10 hours to obtain an anionic bio-exchanger modified with quaternary ammonium salt;

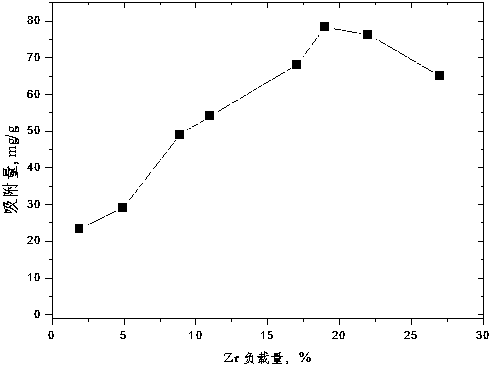

[0037] (2) Weigh 10g of the above bio-exchanger and add 40g of ZrOCl 2 ·8H 2 O and 160mL HCl (0.5mol / L) mixed solution, stirred at 50°C for 6 hours. The material was filtered out with a filter screen and added to 150mL NaOH (15wt%) solution, stirred and reacted at 50°C for 6 hours. After the end, the product was washed with water until neutral, then washed with 10wt% NaCl solution and deionized water, and dried in vacuum at 50°C for 10 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com