Strip mesh screen face coal screening machine with material poking combs

A technology of coal sifter and strip mesh, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of unseen technical solutions, stalls, failure of normal operation of coal sifter, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

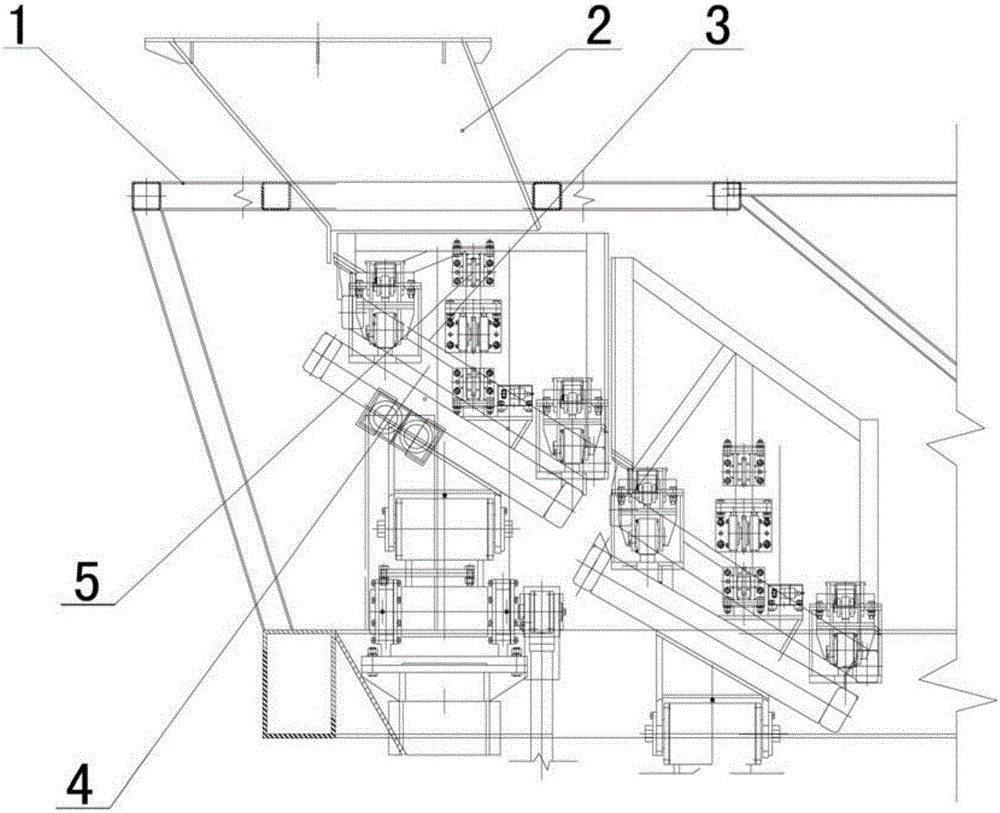

[0032] refer to figure 1 , a kind of strip screen surface coal screening machine with a material comb, including a complete machine frame 1, a feed hopper 2 for introducing incoming materials into the screen body, a plane screen body 3 installed obliquely relative to the ground, and a motor, a speed reduction mechanism, The sieve body reciprocating swing drive device 5 composed of transmission components.

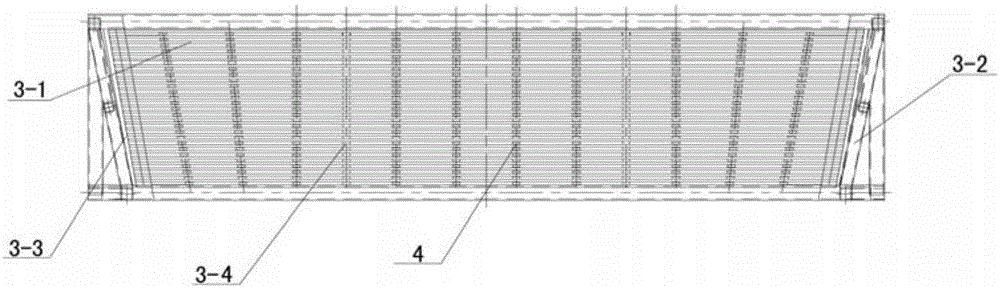

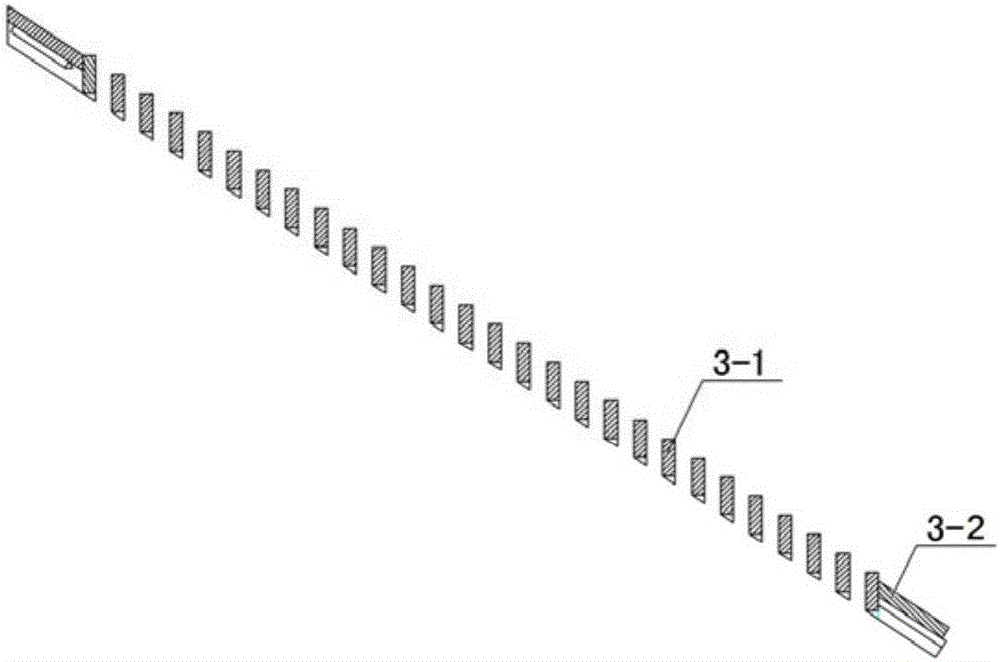

[0033] refer to figure 1 , figure 2 , image 3 , the sieve body 3 is made up of a sieve frame 3-2 and a sheet-shaped sieve bar 3-1 connected to the sieve frame to form a screen. In this embodiment, the sieve bar is arranged vertically to the material flow direction (that is, the length direction is horizontal).

[0034] refer to figure 1 , Figure 4 , Figure 5 , the material comb 4 located under the screen body is composed of comb teeth 4-1 and a tooth seat (comb back) 4-2 that fixes a plurality of comb teeth in a row. The two sides form slopes facing downwards. ...

Embodiment 2

[0042] refer to Figure 10 , a kind of bar screen surface coal sieving machine with comb, comprises complete machine frame 1, the screen body 3 that is installed on the frame.

[0043] refer to figure 2 , image 3 , Figure 10 The sieve body 3 is composed of a sieve frame 3-2, sheet-shaped sieve bars 3-1 fixed on the sieve frame and arranged in parallel at a set interval, and side retaining nets 3-3 erected on the sieve body at both ends of the sieve bar. The wide surface of the sheet-shaped sieve bars is in the vertical direction, and strip-shaped sieve mesh holes are formed between the sieve bars, and the sieve bars are arranged perpendicular to the material flow direction. On the sieve body 3 there are several sieve bars 3-4 intersecting with the sieve bars 3-1 and fixed on the screen frame to support the middle beam 3-4.

[0044] refer to Figure 12 , the sieve body 3 is installed on the frame 1 through the wheels 12 rolling in the bar direction and the rails 11 cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com