A rotating arm type axle box preloading assembly device and method

An assembly method, a technology of the swivel arm type, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient pre-installation of the swivel arm, the need for flanging of the frame, and low production efficiency, so as to solve the problem of the assembly accuracy of the swivel arm Problems, save space, save the effect of production equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

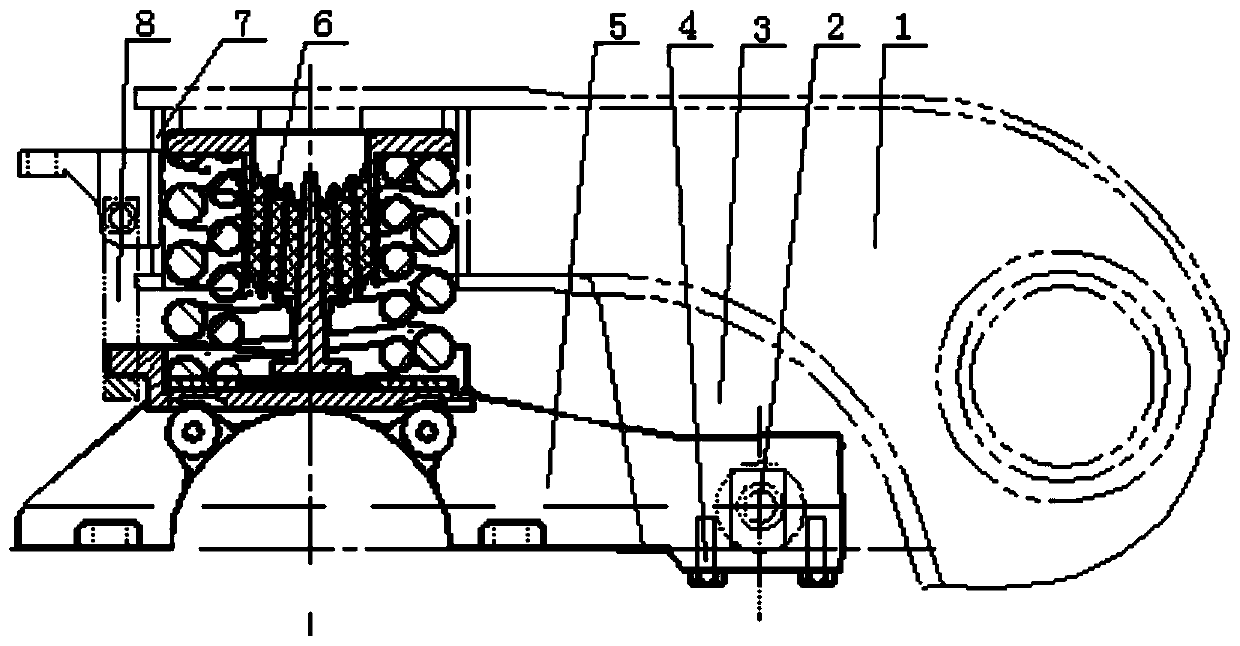

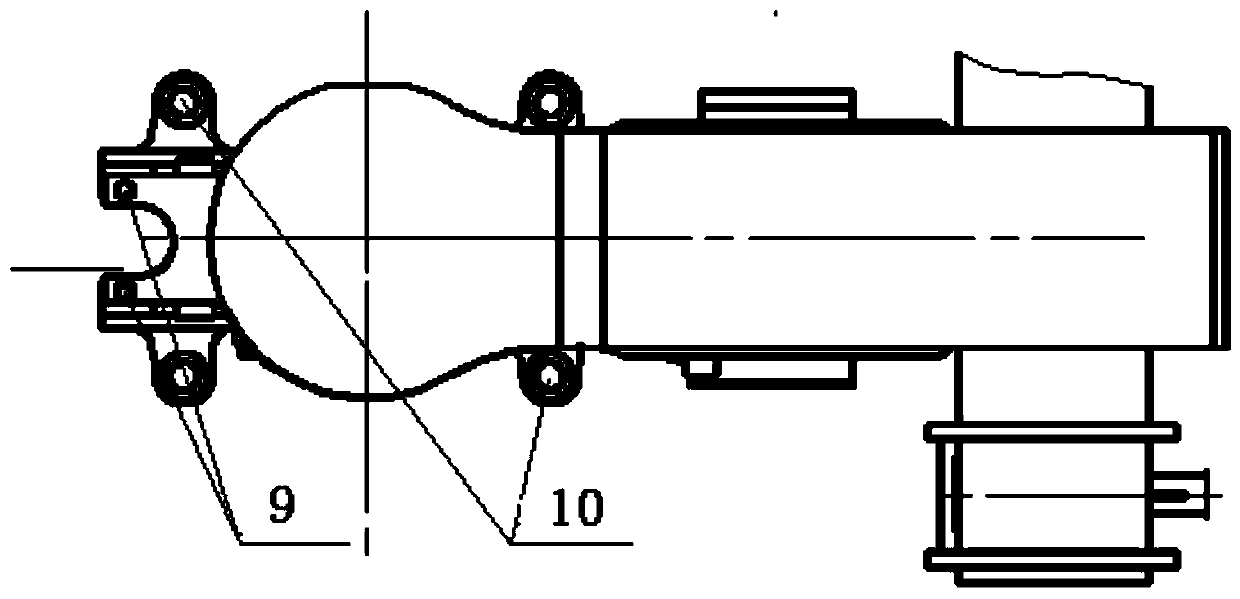

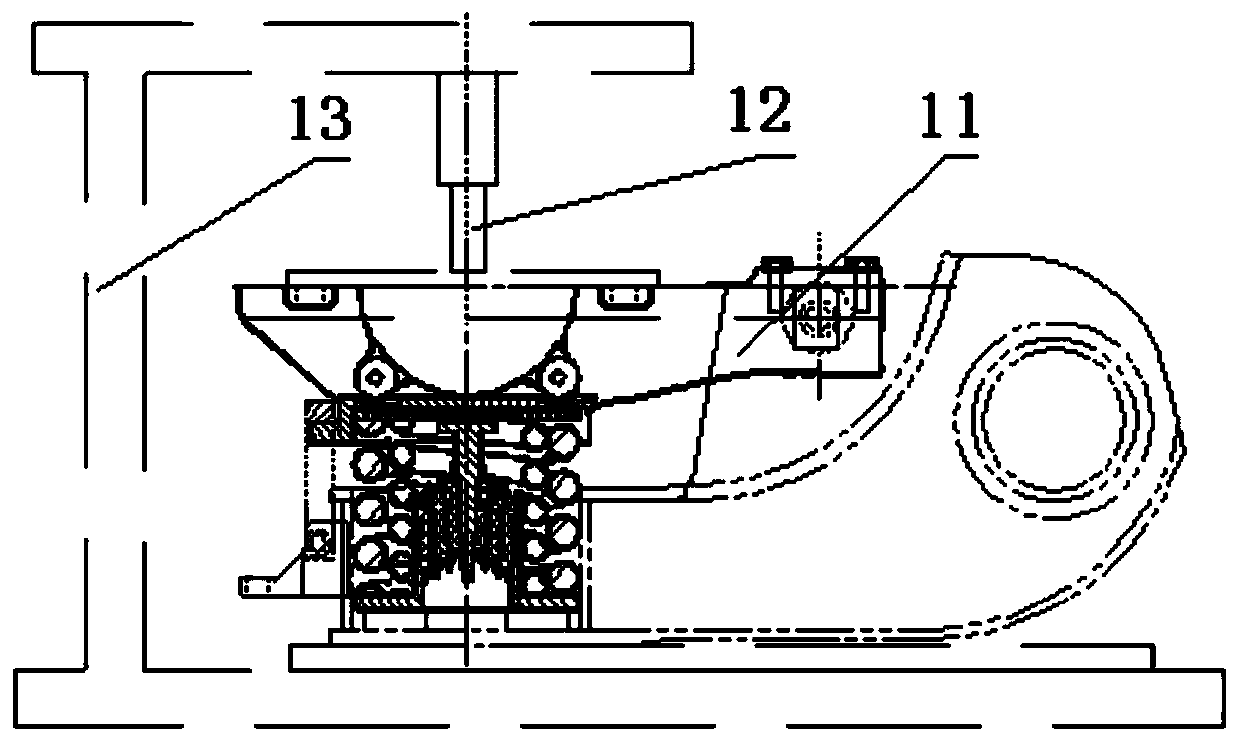

[0030] This embodiment provides the following kind of pivoting arm type axle box preload assembly device, such as image 3 ,as well as Figure 4-1 to Figure 4-4 shown.

[0031] Wherein, the pivoting arm type axle box pre-pressing assembly device includes: a frame positioning and press-fitting guide device 14 and a gantry frame trolley 16 .

[0032] The frame positioning and press-fitting guide device 14 includes a fixed plate 19, and the fixed plate 19 is provided with a positioning pin 17 matched with a hole processed at the end of the frame of the rotary arm type axle box device, and is connected with the compression rotary arm type axle box. The same guide pin 18 of the fixing direction of the spring device 6 of the device and the rotating arm 5;

[0033] The gantry frame trolley 16 is provided with a pressure device 20 that can stretch longitudinally so as to compress the spring device 6 of the pivot arm type axle box device. The pressing head pressing direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com