Drum Washing Machine Stainless Steel Inner Bucket Rotary Riveting Closure Forming Machine

A drum washing machine, stainless steel technology, applied in the field of drum washing machine stainless steel inner barrel rotary riveting closing forming machine, can solve the problems of wrinkles at the junction of the neck and the barrel, deformation of the neck structure, and influence on the installation of plastic parts, so as to improve stability and Accuracy, balanced force, and stable molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

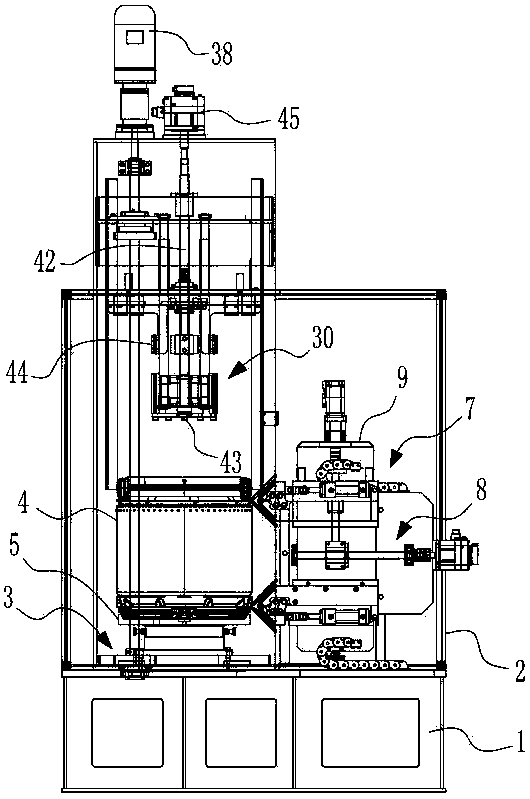

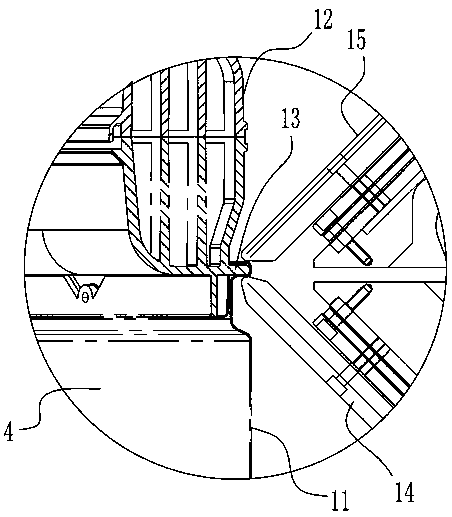

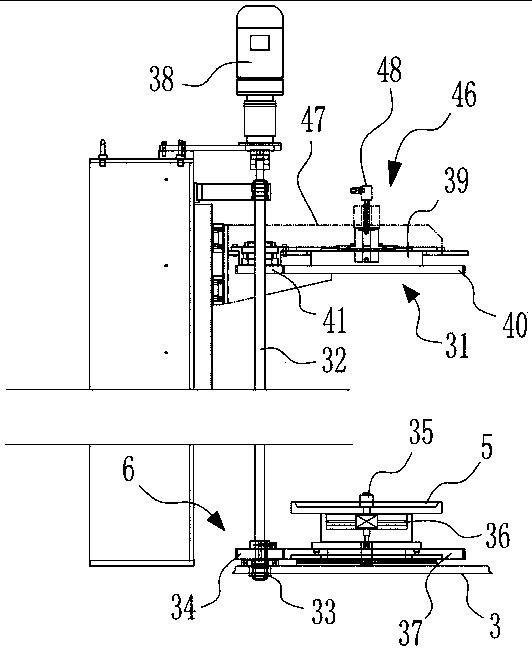

[0022] Such as figure 1 , 2, 3, 4, 5, and 6, a drum washing machine stainless steel inner barrel rotary riveting closing forming machine, including a frame 2 with a box body 1, a workbench 3 is set on the frame 2, and a workbench 3 is set on the workbench 3 There is a turntable 5 for fixing the stainless steel inner barrel 4, and a first drive mechanism 6 for driving the turntable 5 to rotate. On either side of the turntable 5, there are fixed ports on the workbench 3 for the stainless steel inner barrel 4 respectively. A riveting closing mechanism 7 for necking processing at the upper and lower openings, and a feed mechanism 8 for driving the riveting closing mechanism 7 to move radially along the turntable 5. The riveting closing mechanism 7 includes a riveting bracket 9 , along the axial direction of the turntable 5, two rivet heads 10 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com