A kind of comprehensive treatment agent for offshore oil field produced fluid and preparation method thereof

A comprehensive treatment agent and technology for offshore oil fields, which are applied in the field of comprehensive treatment agents for produced liquids in offshore oil fields and their preparation, can solve problems such as deterioration of main indicators of production water systems, difficulty in eliminating them, pollution of sewage treatment equipment, etc., and eliminate the phenomenon of crude oil emulsification. , Strong demulsification and dehydration performance, the effect of improving the demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

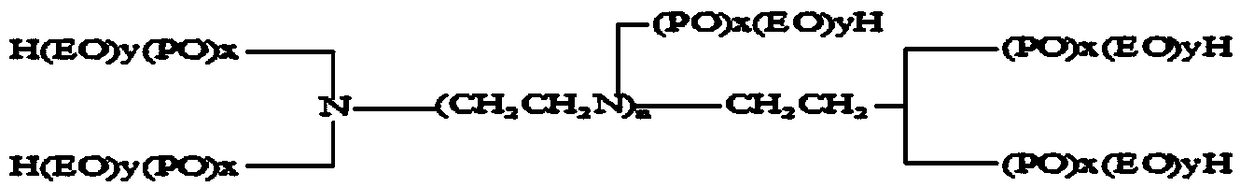

Method used

Image

Examples

Embodiment 1

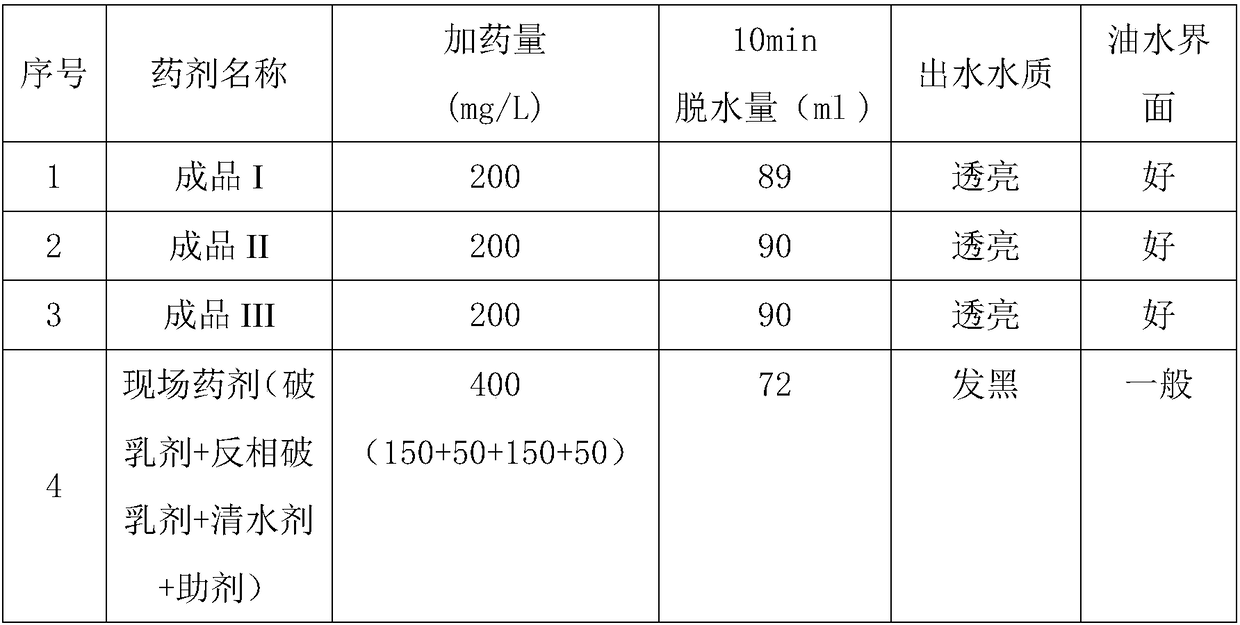

[0016] Preparation of comprehensive treatment agent for offshore oilfield production fluid: In a closed reactor, add 18g of allyl polyether (molecular weight is 3000, wherein EO:PO=0.5:1), and then add 4g of hydrogen-containing silicone oil (hydrogen content 1.58 %), and 1g sodium allyl sulfonate, add catalyst chloroplatinic acid, stir after the reactor repeatedly replaces nitrogen, heat up to 100 ℃ and react for 3 hours, add 8g water-soluble multi-block polyether (molecular weight is 1000, Wherein EO:PO=2:1), heat preservation reaction for 0.5 hours, finally add 1g of acetic acid, 10g of alcohol and 30g of water into the reactor, continue to stir evenly, and finally cool and discharge to obtain the finished product I.

Embodiment 2

[0018] Preparation of comprehensive treatment agent for offshore oilfield production fluid: In a closed reactor, add 18g of allyl polyether (molecular weight is 4000, wherein EO:PO=0.5:1), and then add 4g of hydrogen-containing silicone oil (hydrogen content 1.58 %), and 1g sodium allyl sulfonate, add catalyst chloroplatinic acid, stir after the reactor repeatedly replaces nitrogen, heat up to 100 ℃ and react for 3 hours, add 8g water-soluble multi-block polyether (molecular weight is 1500, Among them, EO:PO=2:1), keep warm for 0.5 hours, and finally add 1g of acetic acid, 10g of alcohol and 30g of water into the reactor, continue to stir evenly, and finally cool and discharge to obtain the finished product II.

Embodiment 3

[0020] Preparation of comprehensive treatment agent for offshore oilfield production fluid: In a closed reactor, after adding 20g of allyl polyether (molecular weight is 3000, wherein EO:PO=0.5:1), add 4g of hydrogen-containing silicone oil (hydrogen content of 1.75 %), and 1g allyl sodium sulfonate, add catalyst chloroplatinic acid, stir after the reactor repeatedly replaces nitrogen, heat up to 105 ℃ and react for 3 hours, add 8g water-soluble multi-block polyether (molecular weight is 1000, Among them, EO:PO=2:1), keep warm for 0.5 hours, and finally add 1g of acetic acid, 10g of alcohol and 30g of water into the reactor, continue to stir evenly, and finally cool and discharge to obtain the finished product III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com