Prefabricated formwork built-in type steel reinforced concrete wall

A concrete wall, built-in technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of damage and waste of wood formwork, large amount of labor for wall masonry, affecting the progress of the project, etc., to shorten the time and reduce the consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

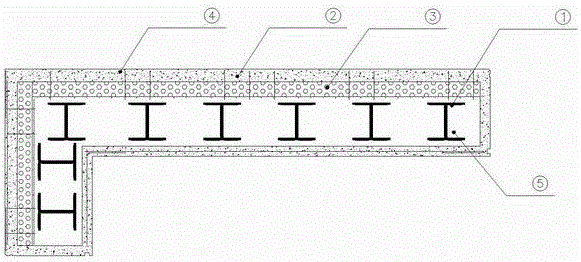

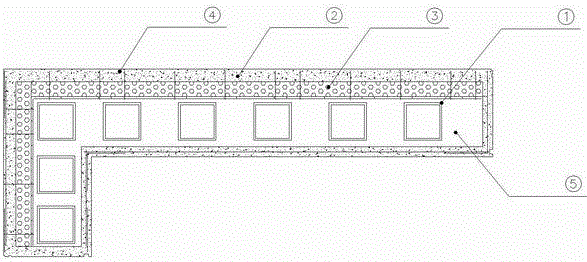

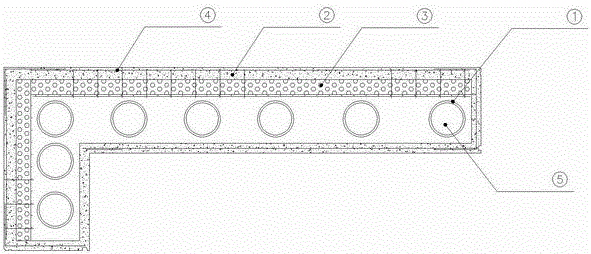

[0030] The present invention is described in detail below by structural drawings:

[0031] A prefabricated formwork with built-in shaped steel concrete wall, the shaped steel 1 is placed in the air in the prefabricated thermal insulation formwork 2, and the concrete wall is formed after the concrete 5 is poured; the shaped steel 1 is used as the stress reinforcement of the wall; the prefabricated thermal insulation formwork 2 is equipped with a steel wire grid 4. As the structural rib of the formwork.

[0032] The formwork concrete and the insulation layer 3 are connected through the steel wire grid 4 to form the formwork main body, or the formwork concrete is only connected through the steel wire grid 4 to form the formwork main body.

[0033] The prefabricated thermal insulation formwork 2 is not only the stressed layer of the prefabricated formwork, which bears the lateral pressure generated when the main body of the structure is poured, but also can be used as the plaster ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com