Flue gas waste heat recovery tower

A flue gas waste heat and recovery tower technology, applied in heat exchanger types, lighting and heating equipment, direct contact heat exchangers, etc., can solve problems such as pollution, energy loss environment, and unsatisfactory heat exchange effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

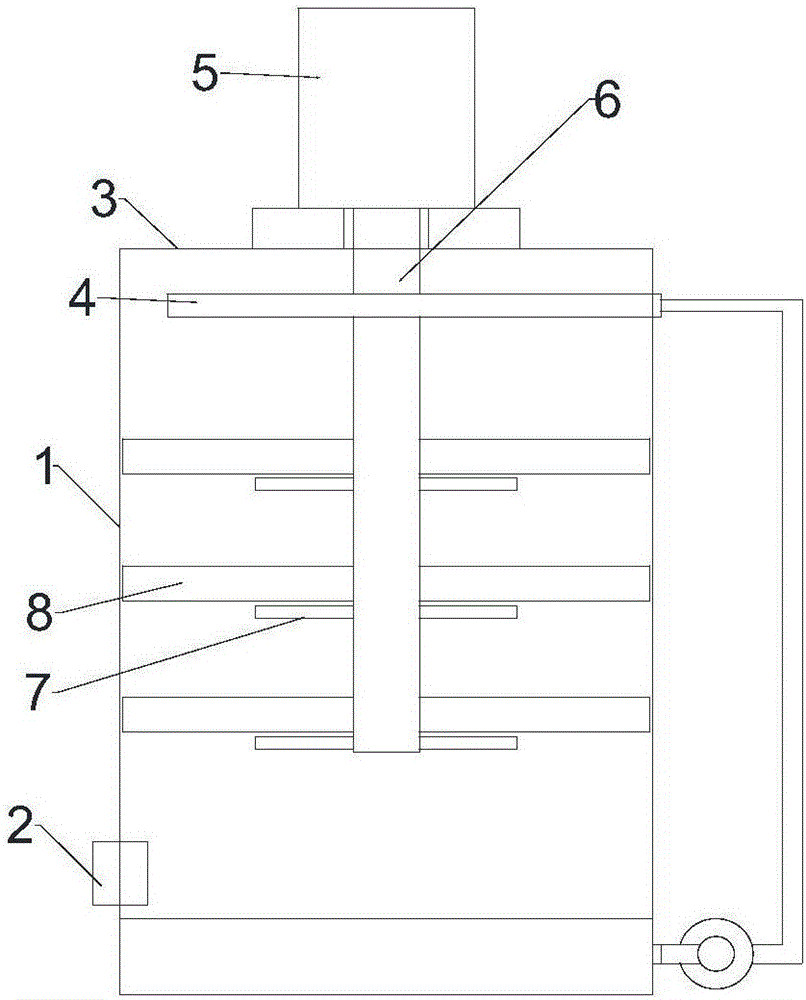

[0012] Depend on figure 1 It can be seen that the flue gas waste heat recovery tower of the present invention includes a tower body 1, an air inlet pipe 2, an air outlet 3, fillers arranged in the tower body 1, and a spray pipe 4. The upper end of the tower body 1 is provided with a lifting device 5, and the lifting device 5 is arranged on the upper end of the tower body 1. The device 5 is provided with a lifting shaft 6, and the lifting shaft 6 extends into the tower body 1. The lifting shaft 6 is provided with external threads, and the lifting shaft 6 is sleeved with a plurality of positioning discs 7 that are threadedly connected with the lifting shaft 6. The packing is composed of a plurality of packing layers 8, the packing layers 8 are supported by the positioning plate 7, and the lifting device is a lifting cylinder.

[0013] After adopting the above structure, according to the size of the air intake and the speed of gas circulation, the gap between the packing layers i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com