Remote field eddy current based metal pipeline defect detection device

A metal pipeline and defect detection technology, which is used in measuring devices, instruments, material analysis by electromagnetic means, etc. Yoke, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

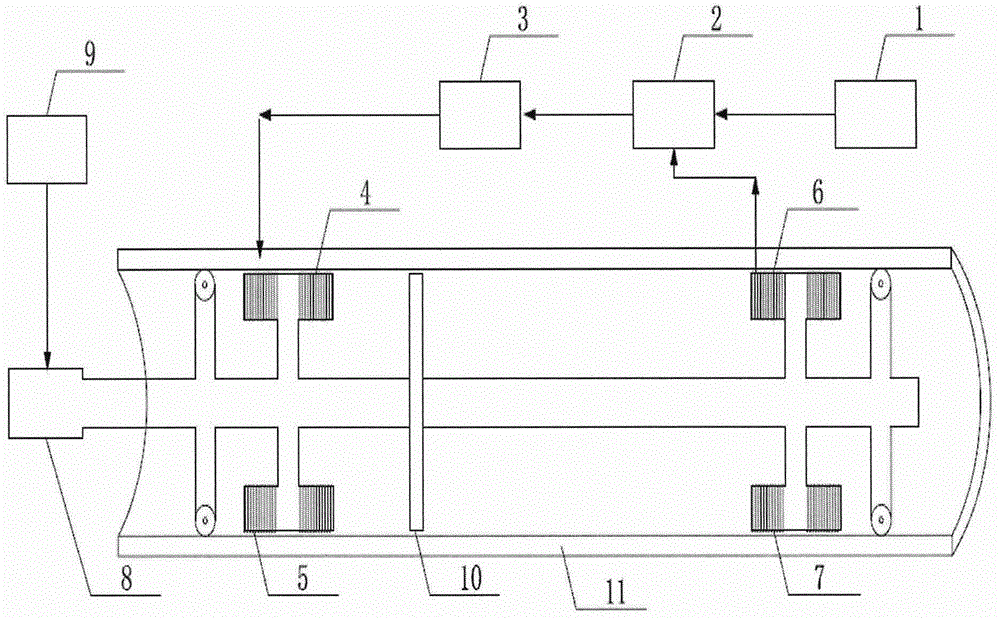

[0016] See attached figure 1 , a metal pipeline defect detection device based on far-field eddy currents, characterized in that: computer (1), STM32 development board (2), power amplifier (3), first excitation coil (4), second excitation coil ( 5), the first detection coil (6), the second detection coil (7), the drive rod (8), the progressive motor (9) and the shielding plate (10); the computer (1) controls the STM32 development board (2) to generate A sinusoidal signal, after being amplified by the power amplifier (3), is loaded on the first excitation coil (4) and the second excitation coil (5), and the generated magnetic field has two different coupling paths when propagating, one is the indirect coupling energy path, the other is the direct coupling energy path, the indirect coupled magnetic field signal is measured through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com