Bearing Internet of Things intelligent production line process control system

A technology of process control system and Internet of Things, which is applied in the field of Internet of Things communication, can solve the problems of higher and higher customer requirements in the high-end market, and achieve the effect of real-time and intelligent, convenient normal operation and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

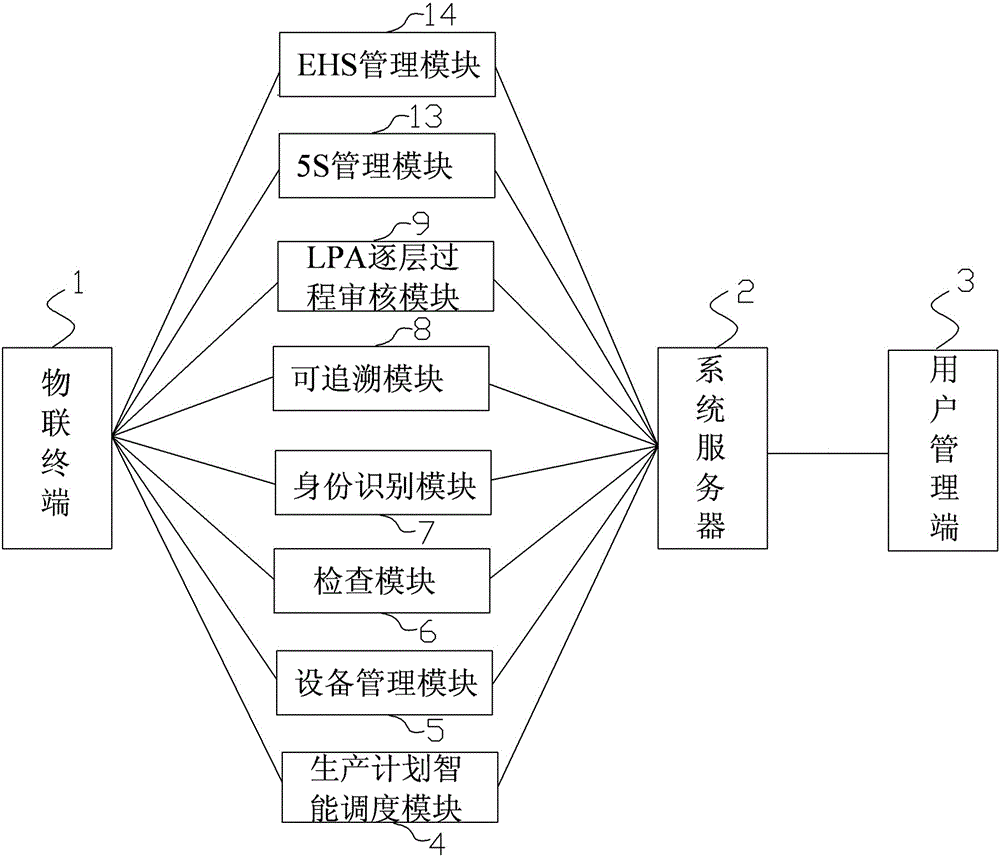

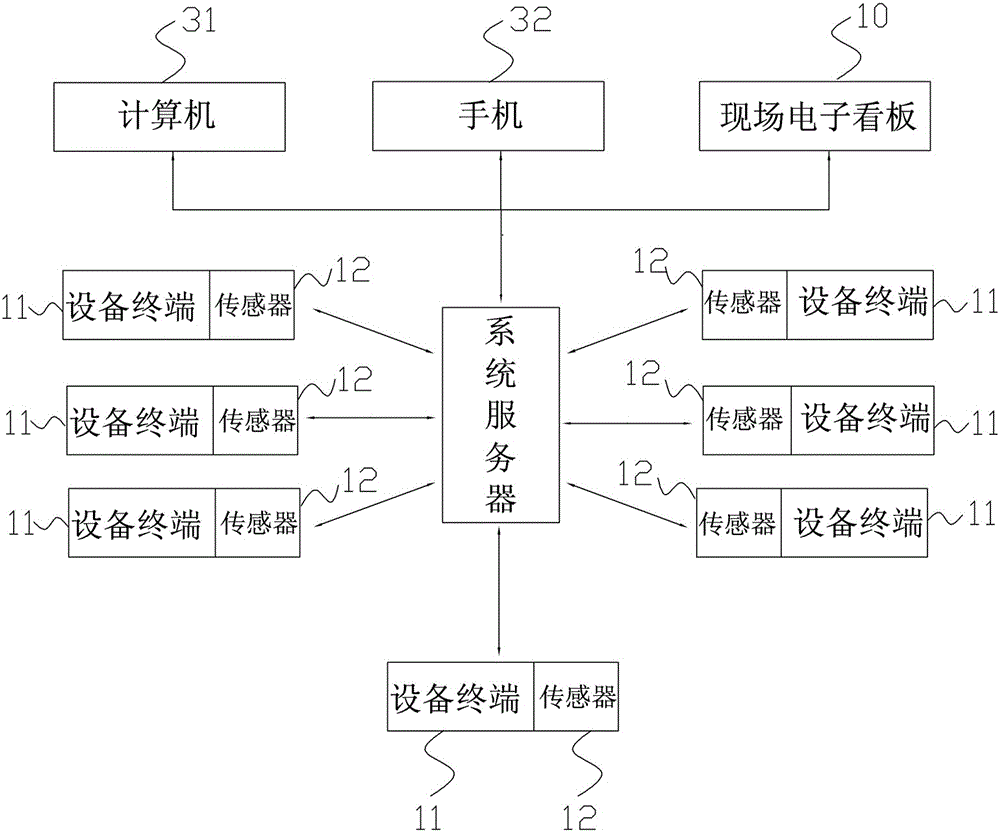

[0015] see Figure 1-2 , the bearing IoT intelligent production line process control system in this embodiment includes a core network composed of the Internet and a mobile communication network, and also includes a user management terminal 3 composed of a computer 31 and a mobile phone 32 for receiving and displaying the system server 2 Forward the IoT operation data, and send execution instructions according to the requirements of the IoT terminal 1; the IoT terminal 1, including each equipment terminal 11 in the tapered roller bearing processing and production process, installs a corresponding sensor 12 on each equipment terminal, and the sensor 12 is used to detect the working status of the IoT device and send i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com