Small high-efficiency overcurrent and overheat protector

A technology of overcurrent, overheating and protector, which is applied in the direction of thermal switch parts, etc., can solve the problems of low current induction, affecting the stability and riveting strength of the assembly riveting of the bottom plate and the shell, and the limited current range, so as to enhance the riveting strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

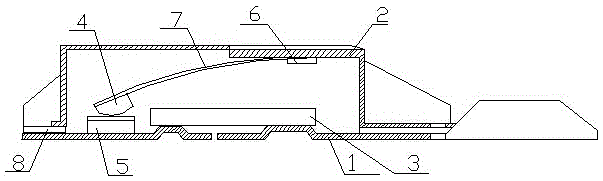

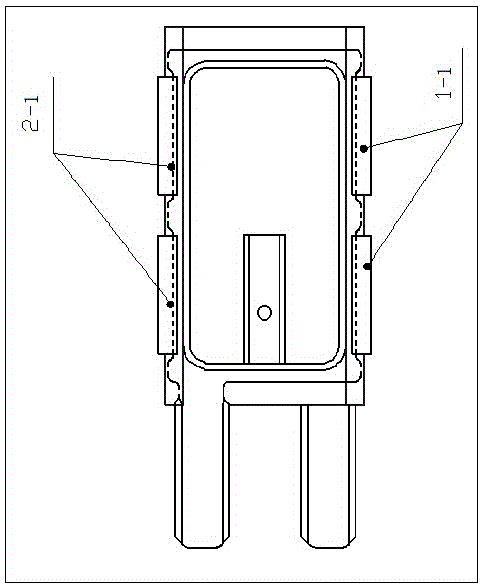

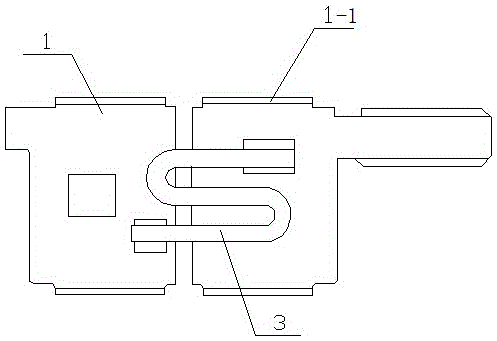

[0009] Such as figure 1 , 2 , 3, including two base plates 1, shell 2, heating wire 3, moving contact 4, static contact 5, fixed plate 6, bimetal sheet 7, insulating paper 8, and the heating wire passes between the two base plates 1 3 connection, the shell 2 is set above the two base plates 1, the static contact 5 is set above one of the base plates 1, the movable contact 4 is set on one end of the bimetal 7 and can be separated and combined above the static contact 5, The other end of the bimetal sheet 7 is connected to the inner top of the shell 2 through the fixed plate 6; the insulating paper 8 is arranged between the two bottom plates 1 and the shell 2; the edges of the two sides of the shell 2 are respectively provided with limiting grooves 2-1, Both sides of the two bottom plates 1 are provided with riveting lugs 1-1 cooperating with the limiting grooves 2-1, and the riveting lugs 1-1 are snapped into the corresponding limiting grooves 2-1 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com