A simple repair method for the transmission cable of the underwater test system

A repair method and test system technology, applied in the direction of insulation/armored cable repair equipment, etc., can solve the problems of damaged transmission cable, inability to effectively deal with transmission, poor toughness, etc., to achieve practical repair work, shorten the test period, and reduce costs. Effect

Inactive Publication Date: 2014-11-05

中国船舶重工集团公司第七六〇研究所

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the thick walls and poor toughness of PV pipes and ABS pipes, these methods cannot effectively deal with transmission

In the case of cable damage and long scratches

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

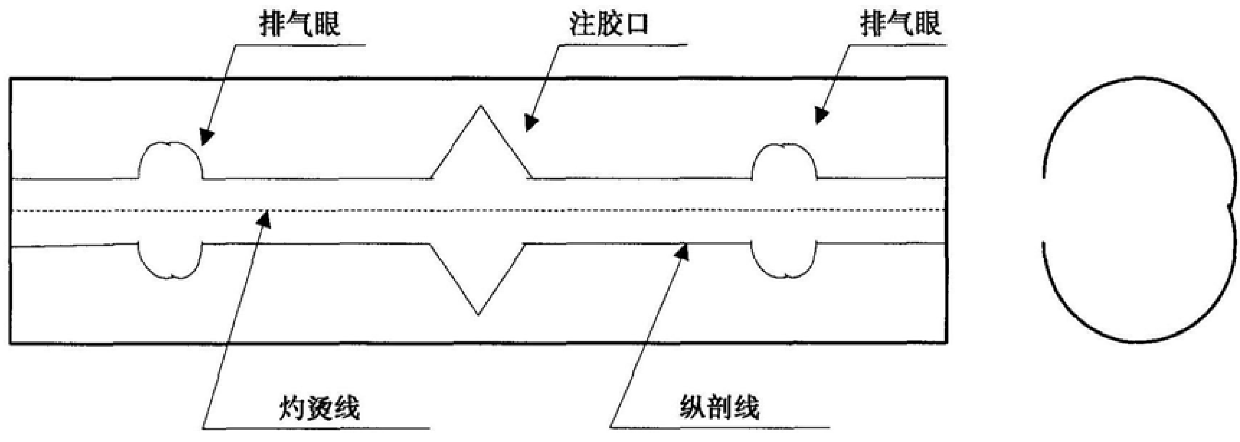

[0010] Fig. 1 is the main and left view of the PE cable pipe, which intuitively shows the manufacturing process of the PE exhaust pipe. According to scratches or

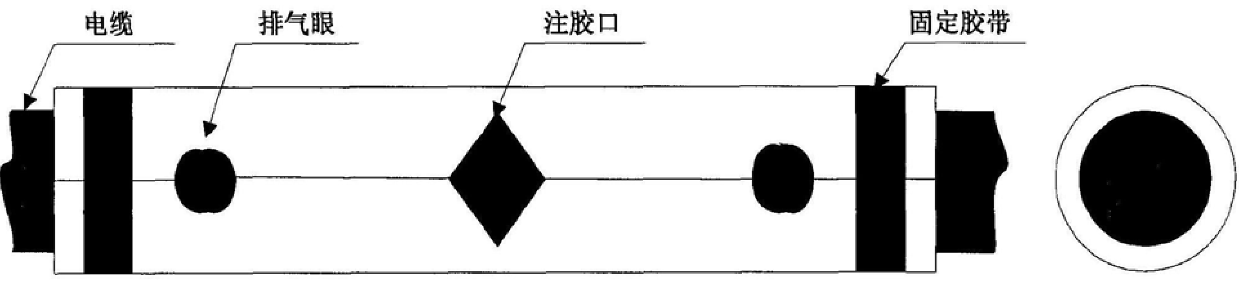

[0014] Second step, the fixing and glue injection of transmission cable.

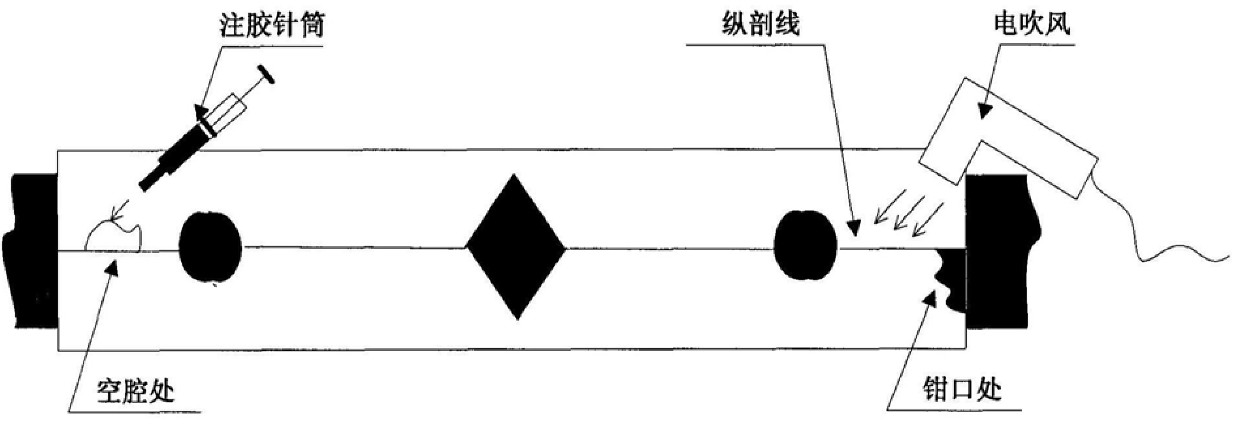

[0017] As shown in Figure 3, after gel injection and solidification, the pouring pipe is removed next. Use a hair dryer to bake against the longitudinal section line,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A simple repair method for transmission cables of an underwater test system belongs to the technical field of underwater cabled test systems. It is characterized in that when the underwater cabled measurement system is recovered, a series of cables are damaged due to the scraping of the seabed rock, the entanglement of the fishing net and the collision during the recovery process. Resolved the repair issue after the transmission cable was recovered. The effects and benefits of the invention are that the PE cable tube is convenient to manufacture, and can be manufactured on site according to the damage of the cable, which is beneficial to efficiently and practically complete the repair work of the cable, reduce the cost and shorten the test period. In the actual repair process, this method can effectively repair various damages and scratches of the cable.

Description

Simple repair method for underwater test system transmission cable Technical field The invention belongs to the technical field of underwater cable testing systems, and relates to a method for repairing underwater transmission cables after use Law. Background technique When reclaiming the underwater cable measuring system, due to the scraping of seabed rocks, the entanglement of fishing nets and the The collision caused a series of damage to the transmission cable, such as cable breakage, scratches, etc., which affected the use of the cable in the next measurement. use. Due to the high price of the transmission cable, replacing the transmission cable will undoubtedly increase the cost of the system and cause unnecessary waste of resources. In response to this situation, many transmission cable repair methods have been produced. At present, the most commonly used method is casted by PV pipe or ABS pipe. method to repair. Due to the thick walls and poor toughness of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C35/00H02G1/16

Inventor 杨国义苏建业董哲邵军

Owner 中国船舶重工集团公司第七六〇研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com