An integrated optimized rebound mechanism for furniture slide rails

A rebound mechanism and slide rail technology, which is applied to household appliances, furniture parts, drawers, etc., can solve the problems of stuck operation, inflexible operation, complicated structure of automatic opening device, etc., so as to avoid the stuck and reduce the difficulty of production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

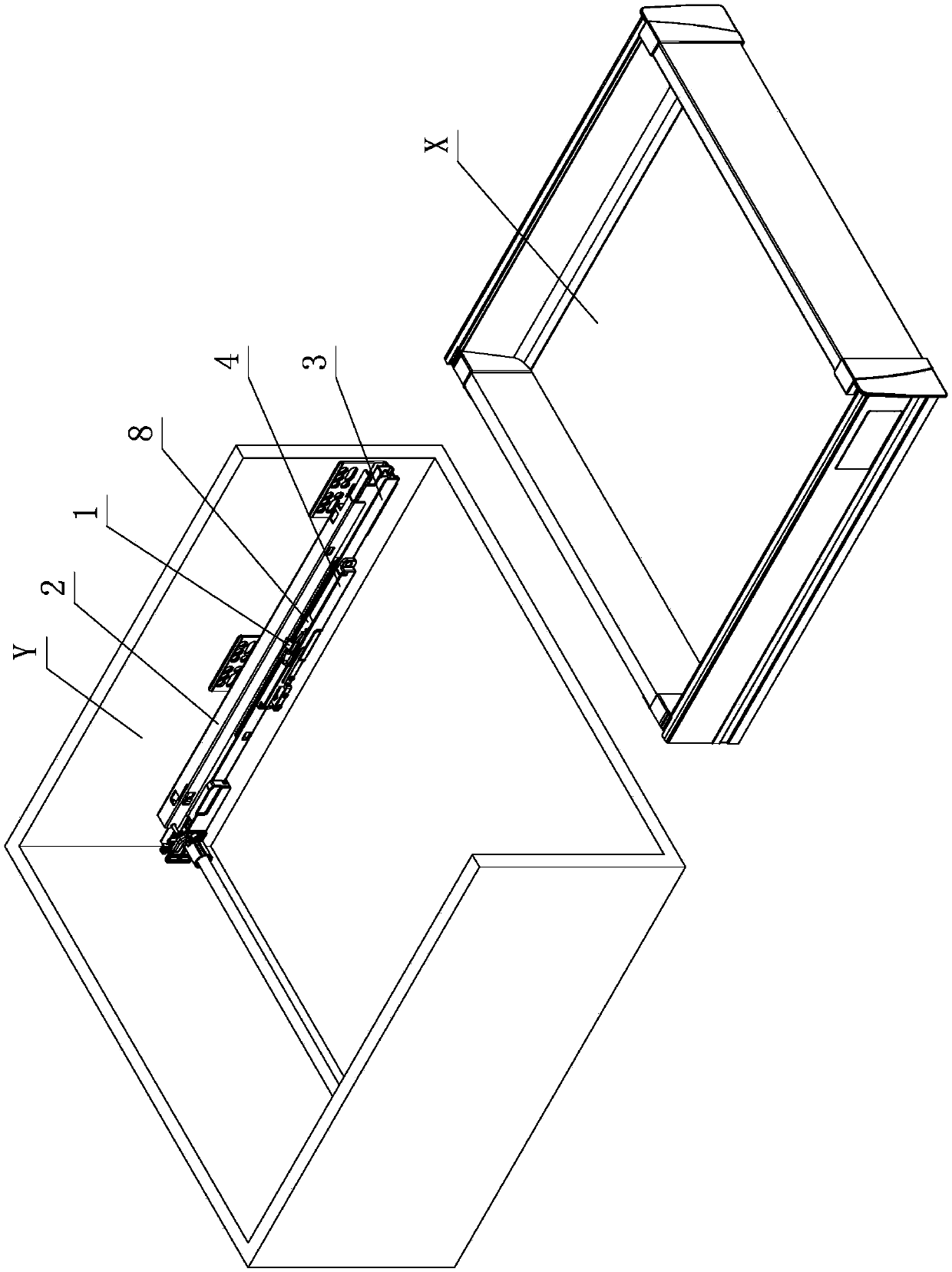

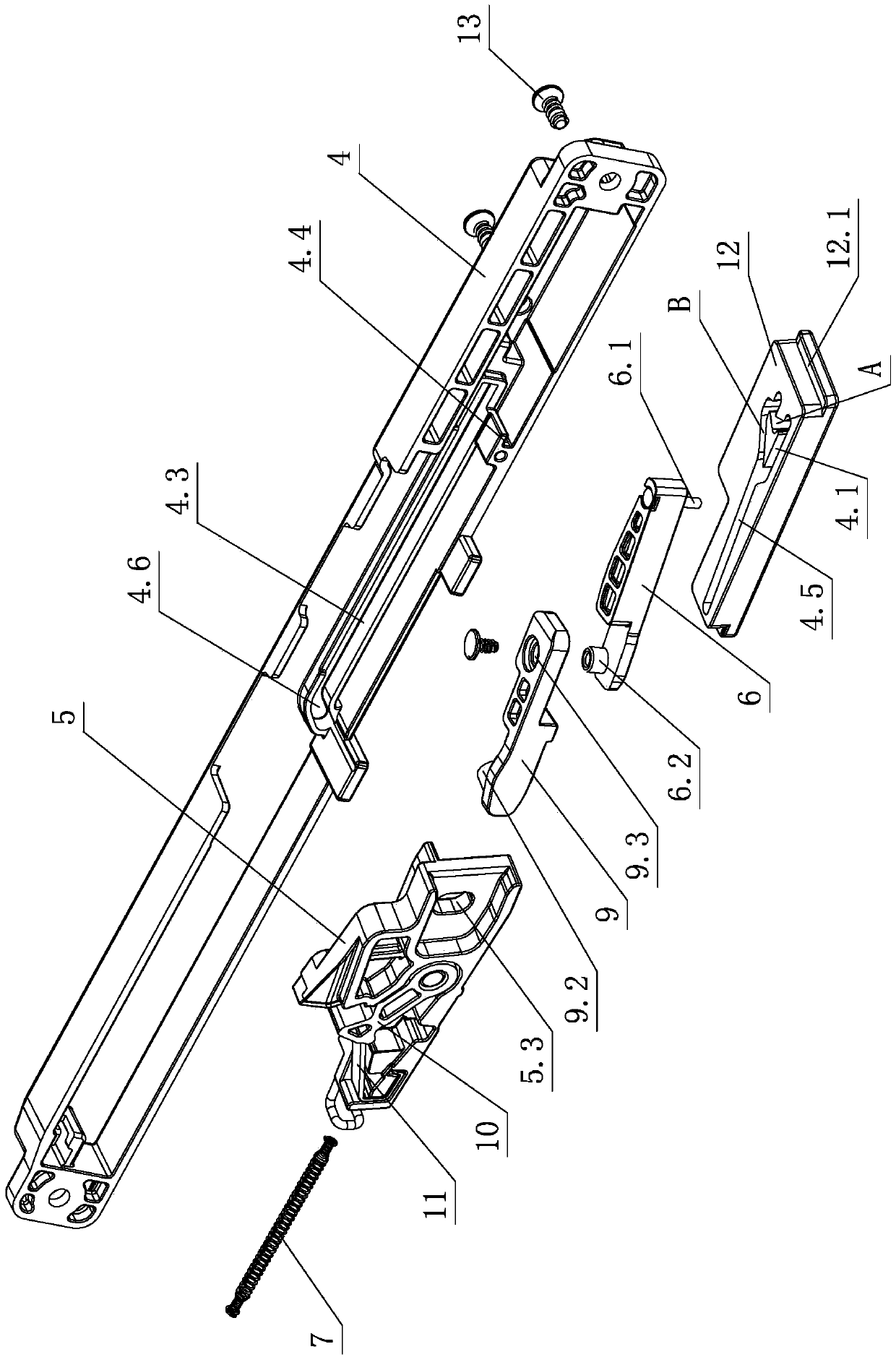

[0021] see Figure 1-Figure 5 , the integrated and optimized rebound mechanism of the furniture slide rail includes a slide rail assembly, a toggle unit 1 and a rebound device. The slide rail assembly includes a moving slide rail 2 and a fixed slide rail 3. Above, the toggle unit 1 is set on the moving slide rail 2, the rebound device is set on the fixed slide rail 3, or the rebound device is set on the moving slide rail 2, the toggle unit 1 is set on the fixed slide rail 3, and the toggle unit 1 Interact with the rebound device at least when the movable slide rail 2 slides and closes relative to the fixed slide rail 3 for a certain stroke. The rebound device includes a fixed bracket 4, a pendulum bolt 5, a push element 6, an adapter element 9 and a heart-shaped chute 12, A positioning matching part is arranged between the fixed bracket 4 and the heart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com