Personalized assembly type dental implant and implant tooth

A technology of dental implants and asanas, which is applied in the fields of dental implants, dentistry, and dental repairs, etc. It can solve the problems of increasing patient pain, prolonging the time of tooth restoration, and being unable to use alveolar sockets, so as to reduce pain and shorten the time of tooth restoration , focus more on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

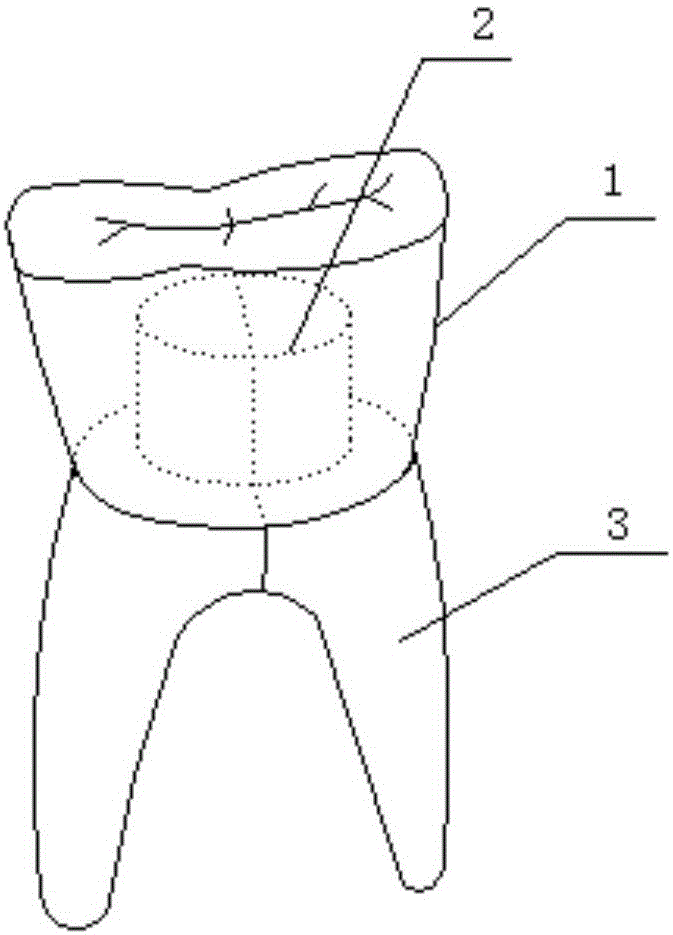

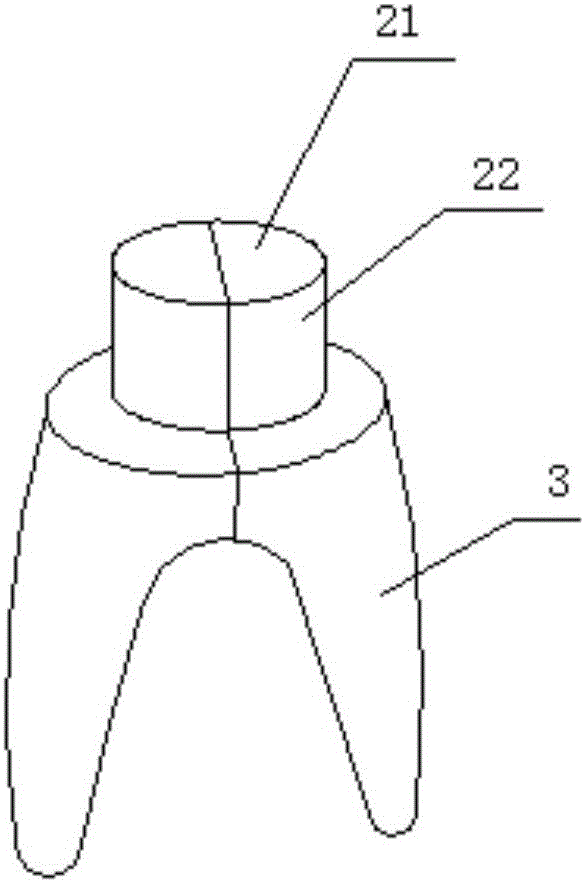

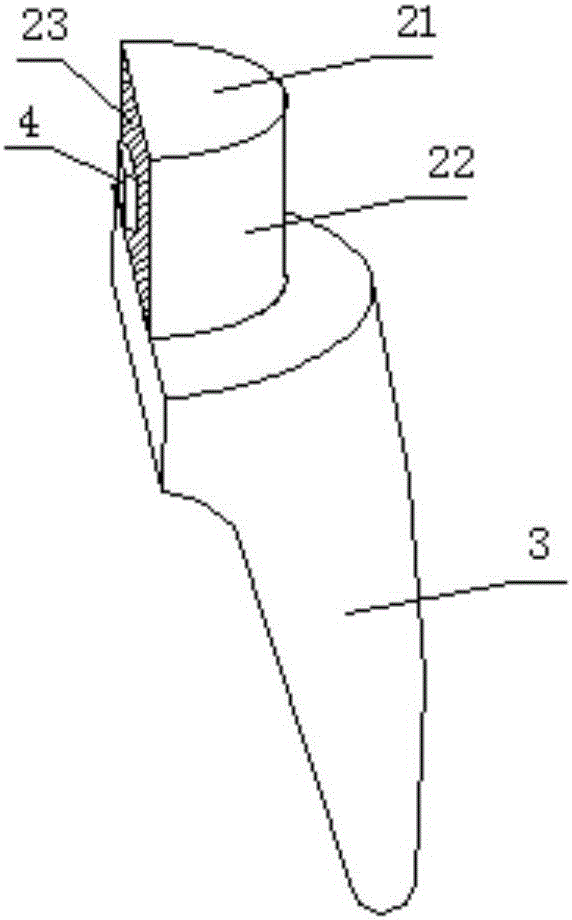

[0044] A personalized modular dental implant, comprising a modular abutment 2 and more than two roots 3, such as figure 2 , the modular abutment 2 is an integral modular abutment 2 formed by combining more than two independent abutments 21, such as image 3 , the top of each tooth root 3 is respectively provided with an independent abutment 21, and each independent abutment 21 is respectively provided with an outer contact surface 22 and more than one inner contact surface 23, and the outer contact surface 22 of the independent abutment 21 fits the crown 1, the inner contact surface 23 of the independent abutment 21 is attached to the inner contact surface 23 of the adjacent independent abutment 21, and the adjacent inner contact surfaces 23 are provided with engaging parts.

[0045] This kind of personalized modular dental implant, by setting the modular abutment 2, can use the original alveolar socket to realize the installation of the dental implant, and the prepared denta...

Embodiment 2

[0064] The structure of the individualized modular dental implant of embodiment two is basically the same as that of embodiment one, and the difference between embodiment two and embodiment one is: as Figure 11 , in the individualized modular dental implant of Embodiment 2, the modular abutment also includes abutment fastening screw 1 24 and a healing cap 25, and abutment fastening screw 1 24 is provided with a crown end and an independent base respectively. On the platform end, the external contact surface of the independent abutment 21 is provided with an external thread, and the connecting abutment end is provided with a groove with an internal thread, and the groove is threaded with the external contact surface of the independent abutment 21 .

[0065] Through the setting of abutment fastening screw 1 24, the connection between the modular abutment and the crown can be made more stable, the durability of the personalized modular dental implant in Embodiment 2 can be increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com