Adult diaper production line and corresponding production technology

A technology for adult diapers and production lines, which is applied in the production process and the production line of adult diapers, can solve the problems of structural improvement, large adult defecation volume, etc., and achieve the effects of improving production effects, reducing production costs, and meeting supply needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

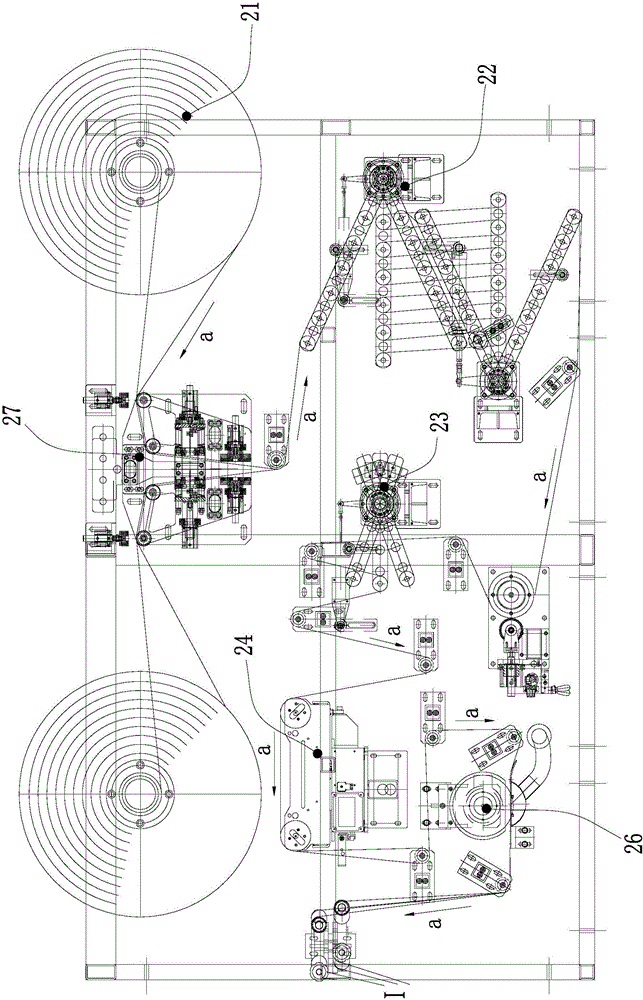

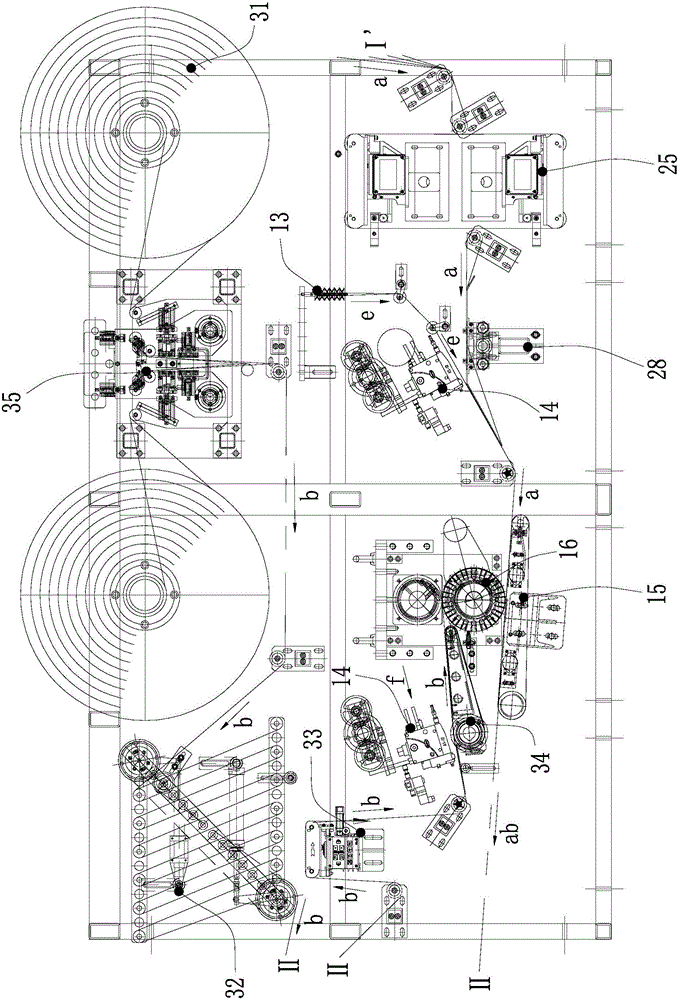

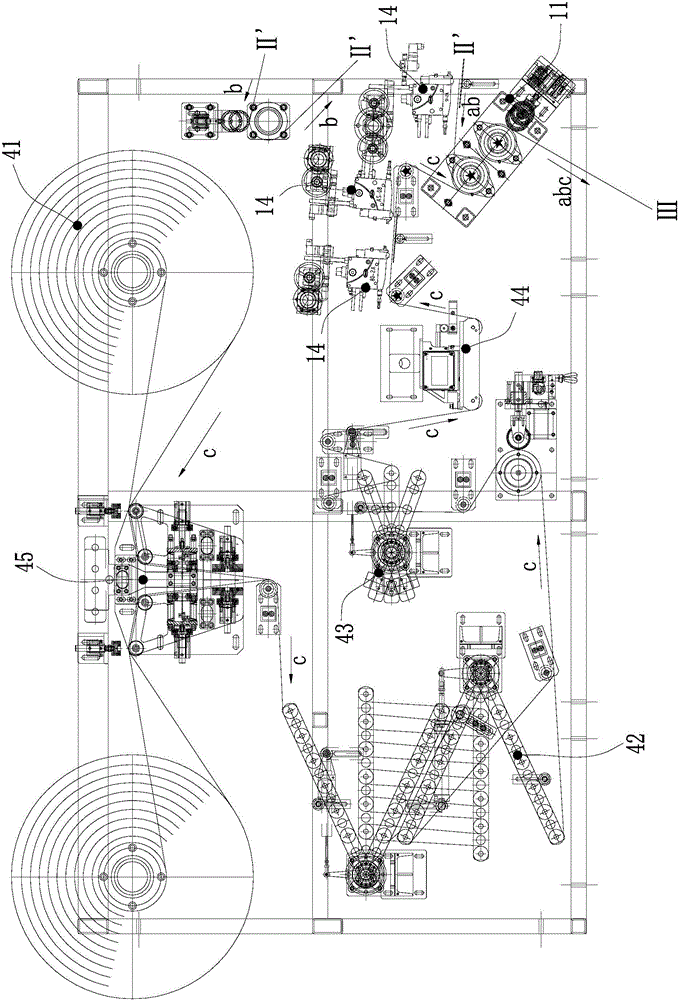

[0037] Such as Figure 1-4 Shown is a production line for adult diapers, the production line includes a water-repellent flank branch a, a water-repellent back wing branch b, a hydrophilic surface layer branch c, an absorbent core branch d, and a leak-proof bottom layer branch , an elastic conveying assembly, a water-repellent layer composite assembly, a first composite transfer roller 11 and a second composite transfer roller 12 . The water-repellent side wing branch a, the water-repellent rear wing branch b, and the elastic conveying components are combined to form the water-repellent surface layer branch ab, and the water-repellent surface layer branch ab is combined with the hydrophilic surface layer branch c to form the surface layer The branch abc, the surface layer branch, the absorbent core branch d, and the leakage-proof bottom layer branch are combined to form the finished product G. The specific structure is as follows:

[0038] The water-repellent flank branch a r...

Embodiment 2

[0047] This embodiment provides a production process for adult paper diapers, which is implemented using the production line in Example 1, and specifically includes the following steps:

[0048] 1), the water-repellent flank is formed; the transmission of the flank material of the water-repellent flank is adjusted by tension and direction correction, and the flank material is cut into left and right parts along the conveying direction with a cutting knife 26, and then introduced onto the elastic-coated platform 28; After the first elastic branch e passes through the gluing process of the glue spraying assembly 14, it is pasted and compounded with the side wing material on the elastic coating platform 28. Specifically, the wing material of the water-repellent wing is drawn out from the water-repellent wing feeding rack 21, the second tension adjustment is performed through the first tension swing frame 22 and the second tension swing frame 23, and the first direction adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com