Winding method for automatic torque conversion of carbon-free car and carbon-free car

A carbon-free car, winding method technology, applied in toy cars, toys, entertainment and other directions, can solve the problem of not being able to solve the problem of timely automatic adjustment of the driving force of the uphill and downhill track, inability to achieve the requirement of climbing ability, inability to meet, etc. Achieve the effect of novel and unique principle, simple and fast method, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

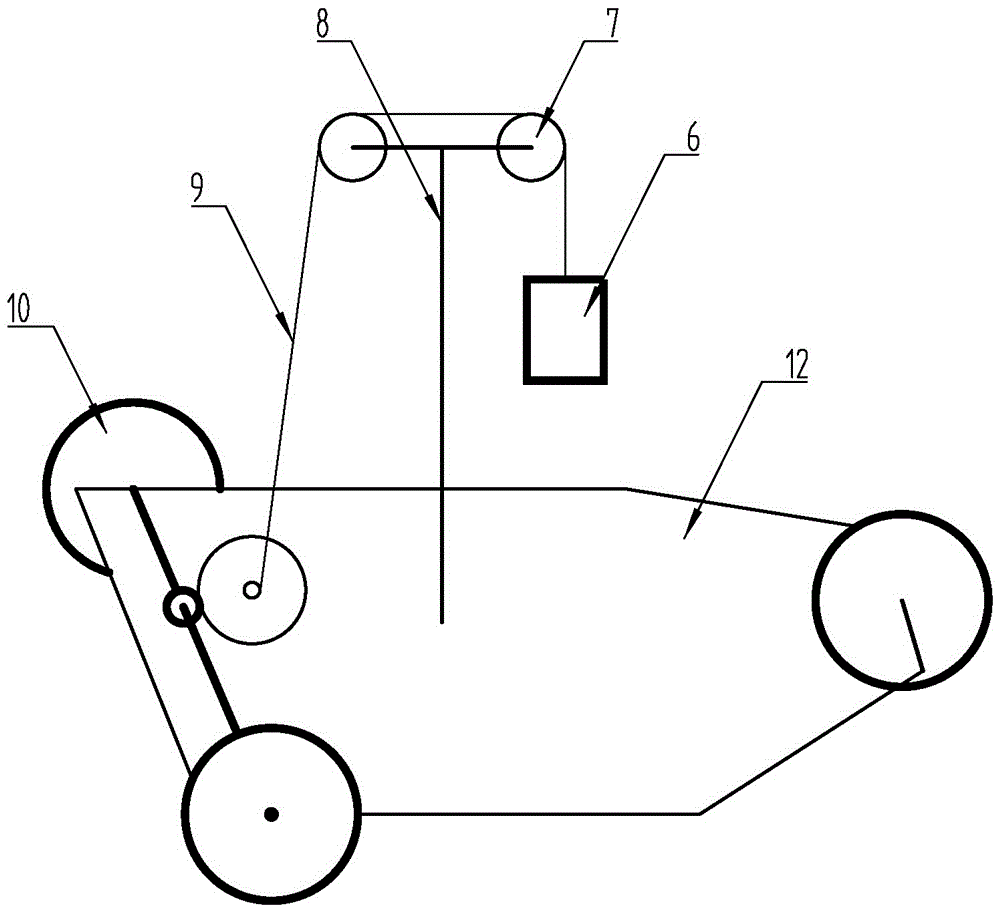

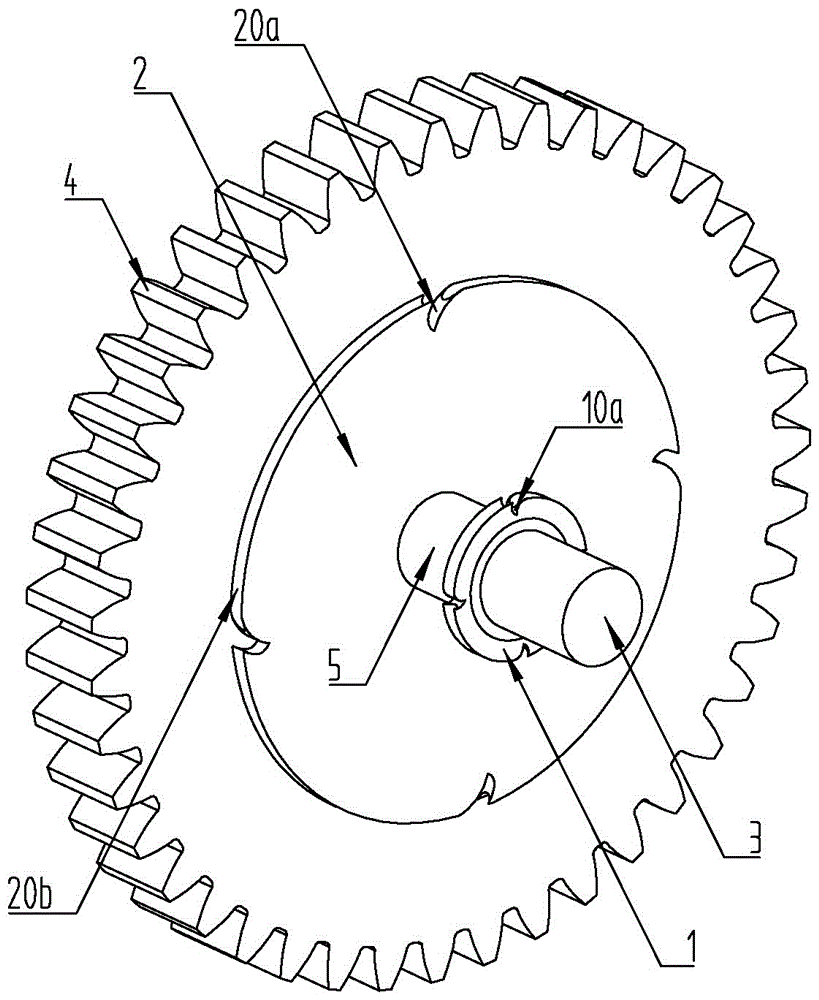

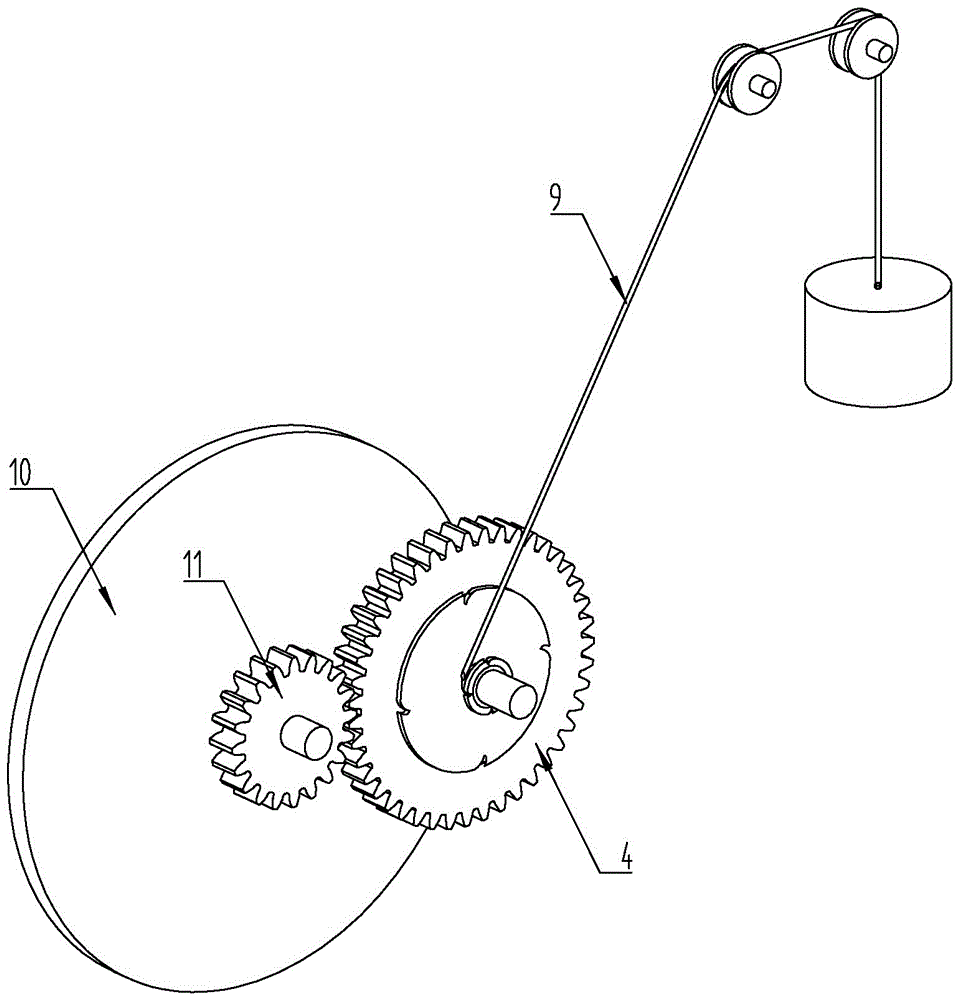

[0023] Such as Figures 1 to 3 Shown, a kind of carbonless trolley comprises wheel 10, car body 12, column 8, pulley block 7, traction rope 9, output shaft 3, weight 6, starting wheel 1, reel 5 and climbing wheel 2. The wheel 10 is installed on the vehicle body 12 through the rotation of the wheel shaft, the column 8 is vertically arranged on the vehicle body 12 , and the pulley block 7 is arranged on the top of the column 8 . The climbing wheel 2, the winding wheel 5 and the starting wheel 1 are all abutted on the output shaft 3, and the starting wheel 1 and the climbing wheel 2 are located on both sides of the winding wheel 5 respectively. The output shaft 3 is connected with the axle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com