Renewable microporous-mesoporous composite adsorbent and its preparation method and application

A technology of composite materials and adsorbents, applied in chemical instruments and methods, adsorption purification/separation, ethylene production, etc., can solve the problems of pending development, undeveloped research, low preparation efficiency of mesoporous-microporous zeolite materials, etc., to achieve Long service life, low adsorption heat effect, and shortened synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

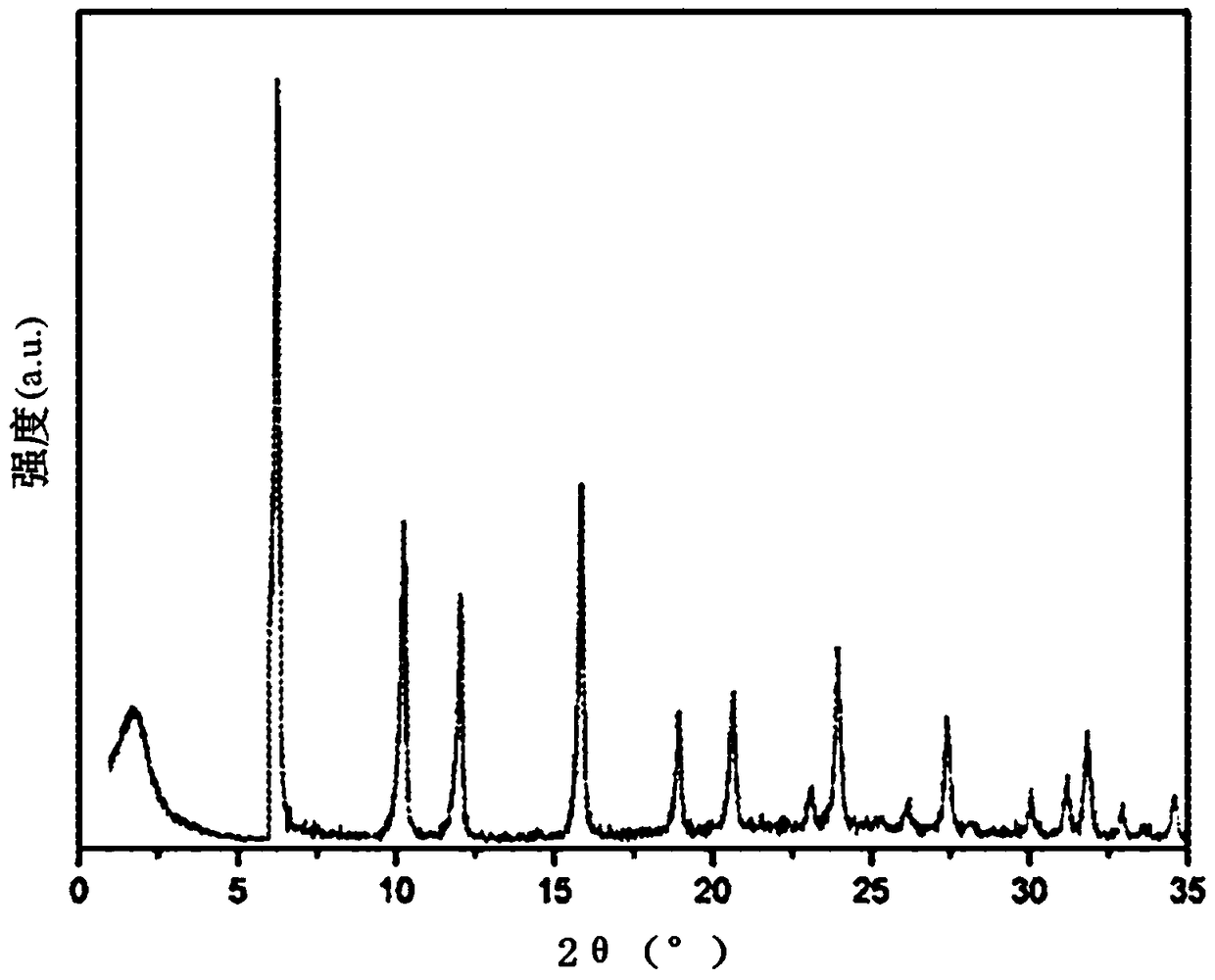

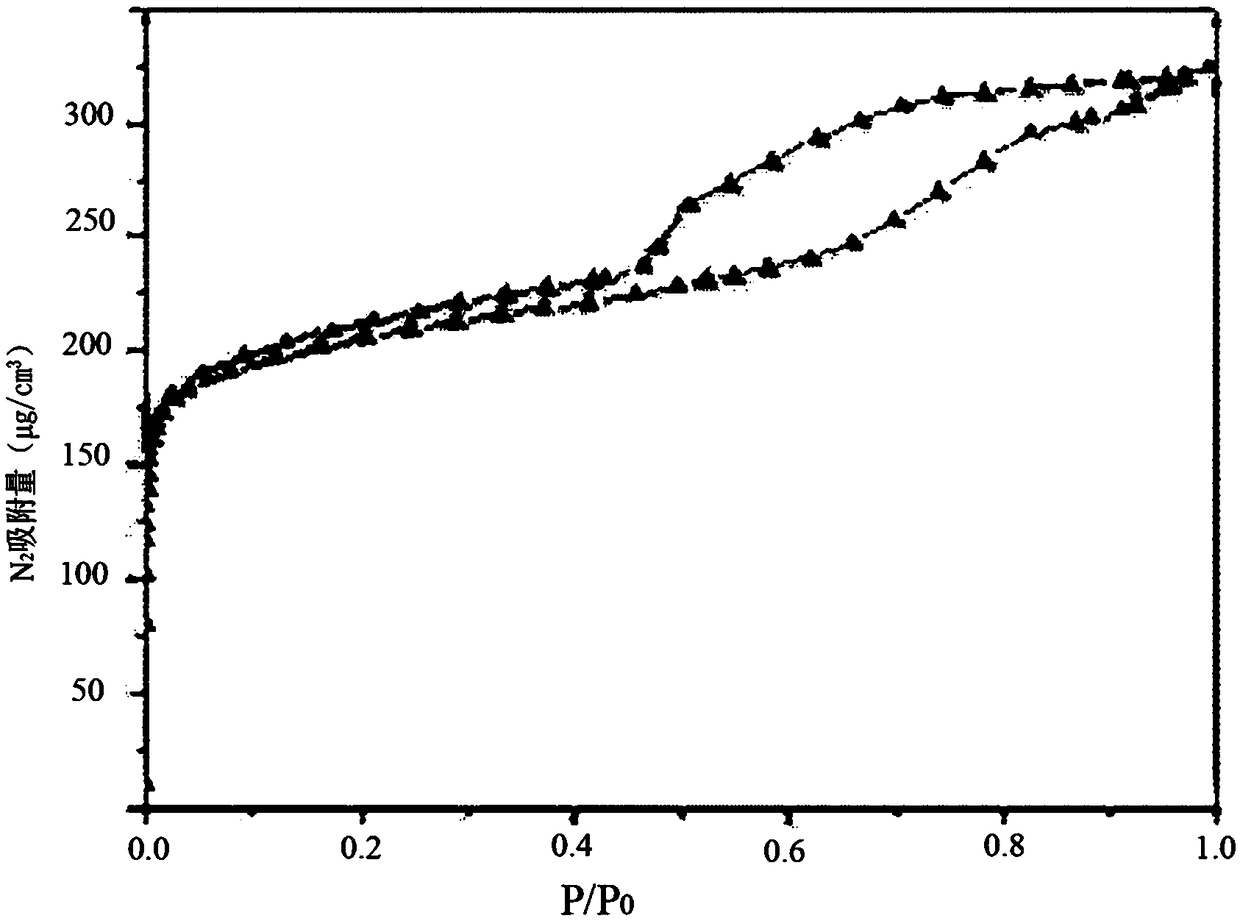

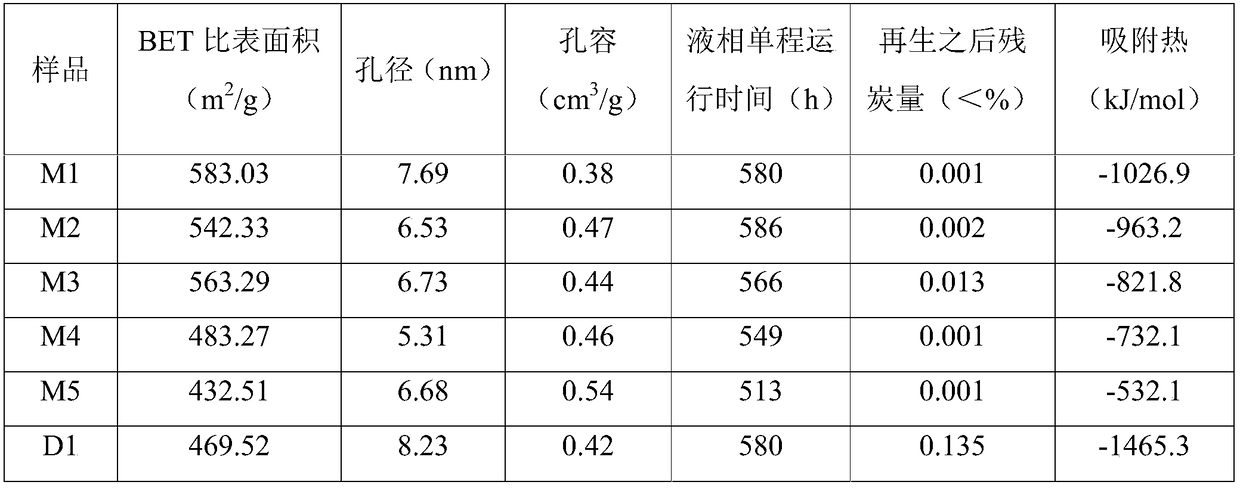

[0051] Mix 2 parts of sodium hydroxide, 1 part of alumina, and 10 parts of water to prepare sodium aluminate, then add 0.01 part of cetyltrimethylammonium bromide, and stir and mix for 4 hours. Add 50 parts of water and 1 part of aluminum nitrate solution, stir at 25°C for 12 hours, and age at room temperature for 24 hours to obtain solution A; weigh 1.5 parts of FAU molecular sieve, add 10 parts of 2.5mol / L sodium hydroxide The solution was ultrasonically treated for 30 minutes to obtain solution B; solution A and solution B were mixed at room temperature, and microwave crystallized at 90°C for 50 minutes, washed and dried to obtain product M1.

Embodiment 2

[0053] The difference from Example 1 is that the solid FAU secondary unit B of the treated FAU molecular sieve is obtained by drying the FAU molecular sieve after ultrasonic treatment with alkali. Then solutions A and B were mixed at room temperature, and microwave crystallized at 90° C. for 50 min, washed and dried to obtain product M2.

Embodiment 3

[0055] Mix 3 parts of sodium aluminate, 100 parts of water, and 0.1 part of P123 template at room temperature for 6 hours, then add 1 part of aluminum nitrate and 177 parts of water, and stir for 12 hours at room temperature to obtain solution A; weigh 1 part of FAU type molecular sieve, add 10 parts of 3.0mol / L NaOH solution, ultrasonic treatment for 10min, then add 10 parts of isopropanol, and treat it under ultrasonic for 20min to obtain solution B; mix solution A and solution B, and stir at room temperature for 12h , followed by microwave crystallization at 95° C. for 60 min, centrifugation, washing and drying to obtain the product M3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com