Unloading multi-station glasses tube integral forming machine

A spectacle tube and multi-station technology, applied in forming tools, positioning devices, manufacturing tools, etc., can solve problems such as low production efficiency and unsafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

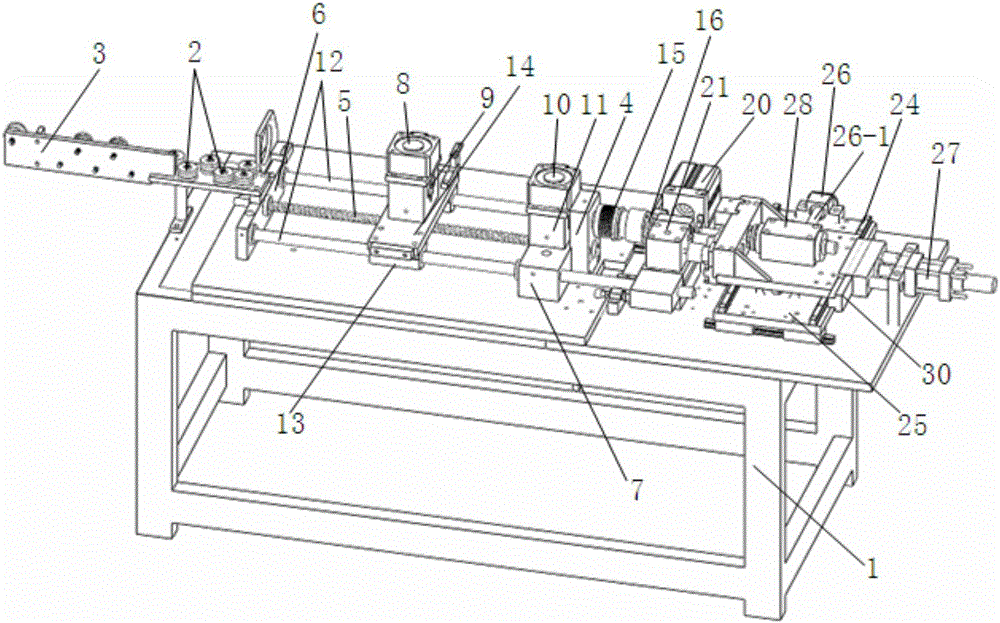

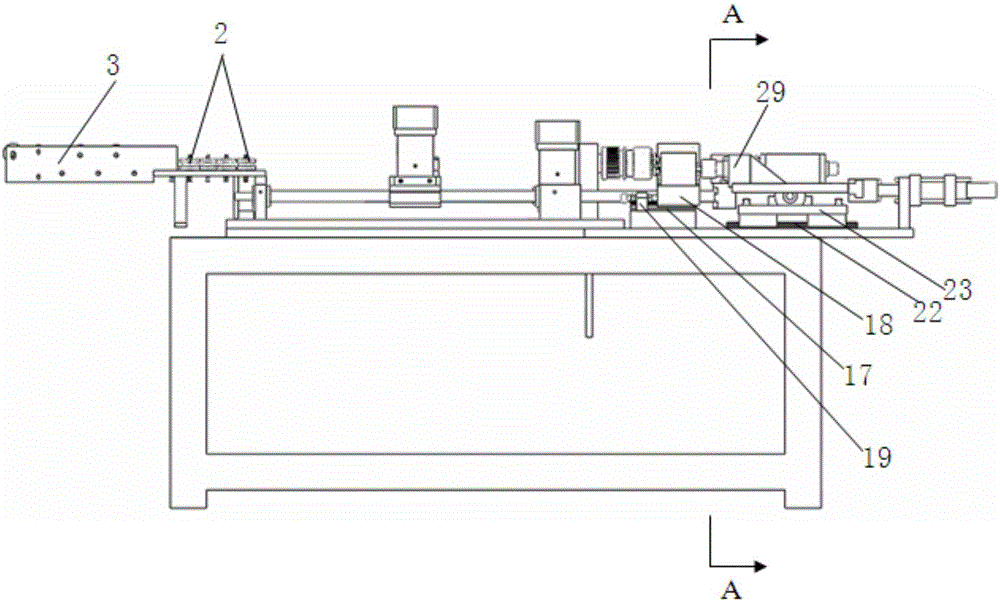

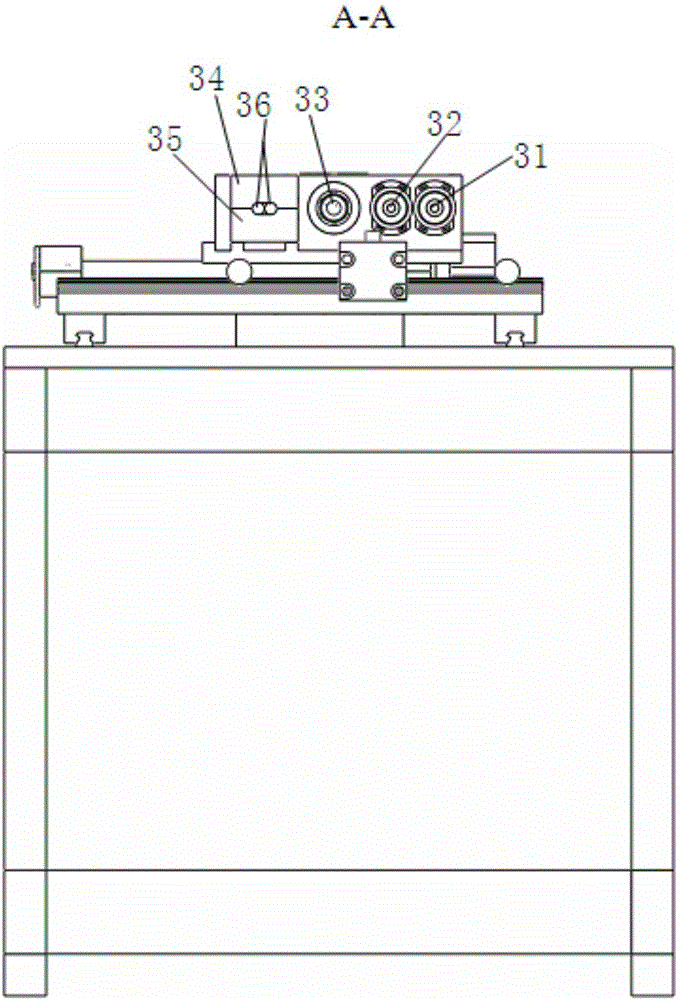

[0020] See attached Figure 1-8 As shown, the blanking multi-station spectacle tube integrated molding machine includes a frame 1 and a straightening mechanism, a feeding mechanism, a chip-free cutting mechanism, a tube end forming mechanism and a control system arranged on the frame 1. The straightening mechanism is composed of straightening wheels 2 installed on the straightening plate 3; the feeding mechanism includes the first motor 4, the first screw 5, the first fixed plate 6, the second fixed plate 7, the first cylinder 8 , the first clamping mold 9, the second cylinder 10, the second clamping mold 11, the cylindrical guide rail 12, the guide sleeve 13 and the first slide plate 14, and the described cylindrical guide rail 12 passes through the guide sleeve 13 and is fixed on the first fixed plate 6 and Between the second fixed plates 7, the first slide plate 14 is installed on the guide sleeve 13, and the first clamping mold 9 is fixed on the first slide plate 14 and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com