Big plane wing assembly working platform

A technology of assembly work and work platform, which is applied in the direction of aircraft assembly, etc., can solve the problems of difficult manufacturing, large workshop space requirements, complex mechanism, etc., and achieve the effect of reducing workshop space requirements and good synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

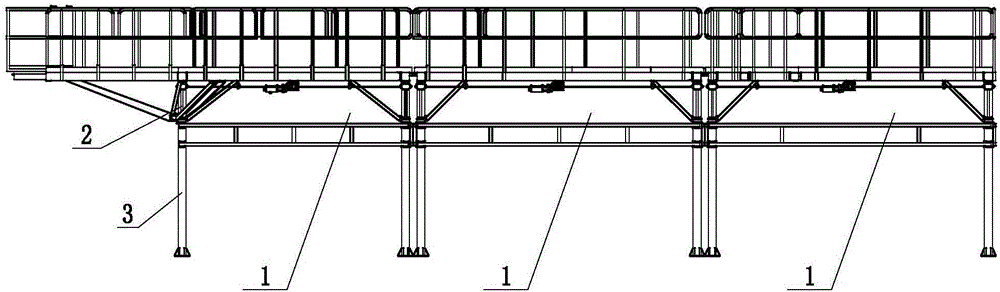

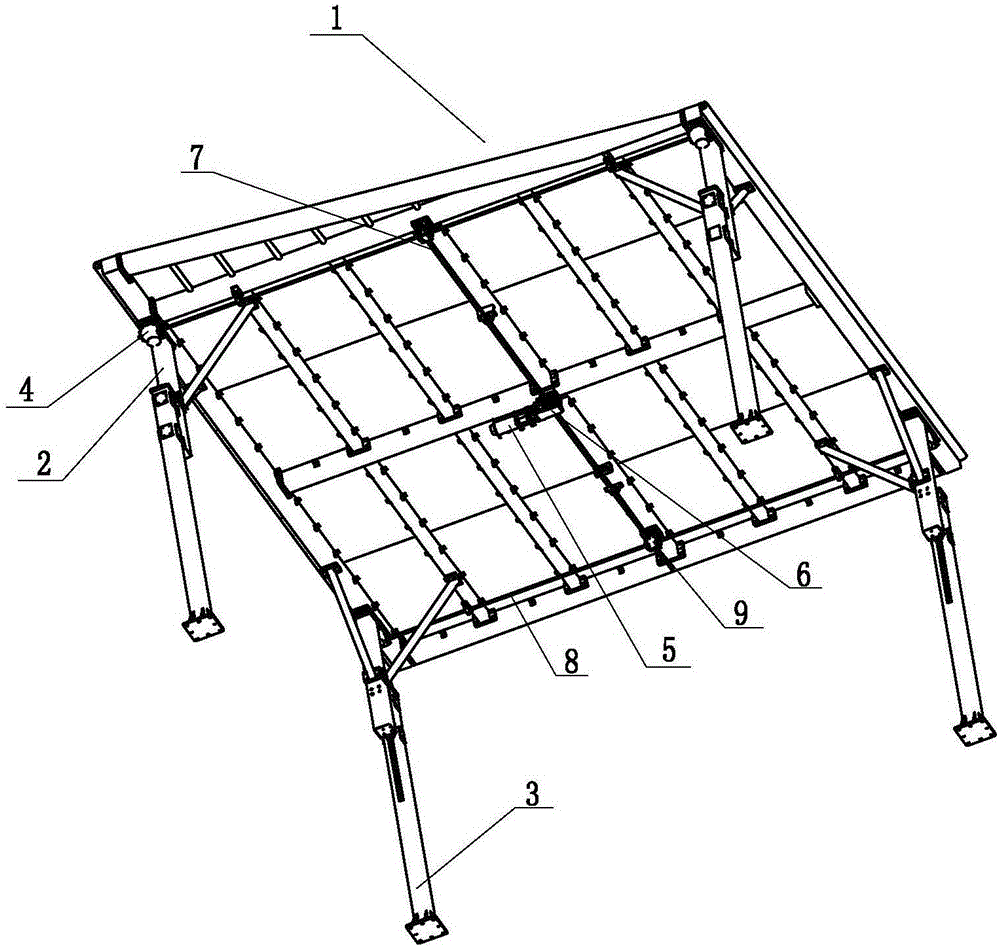

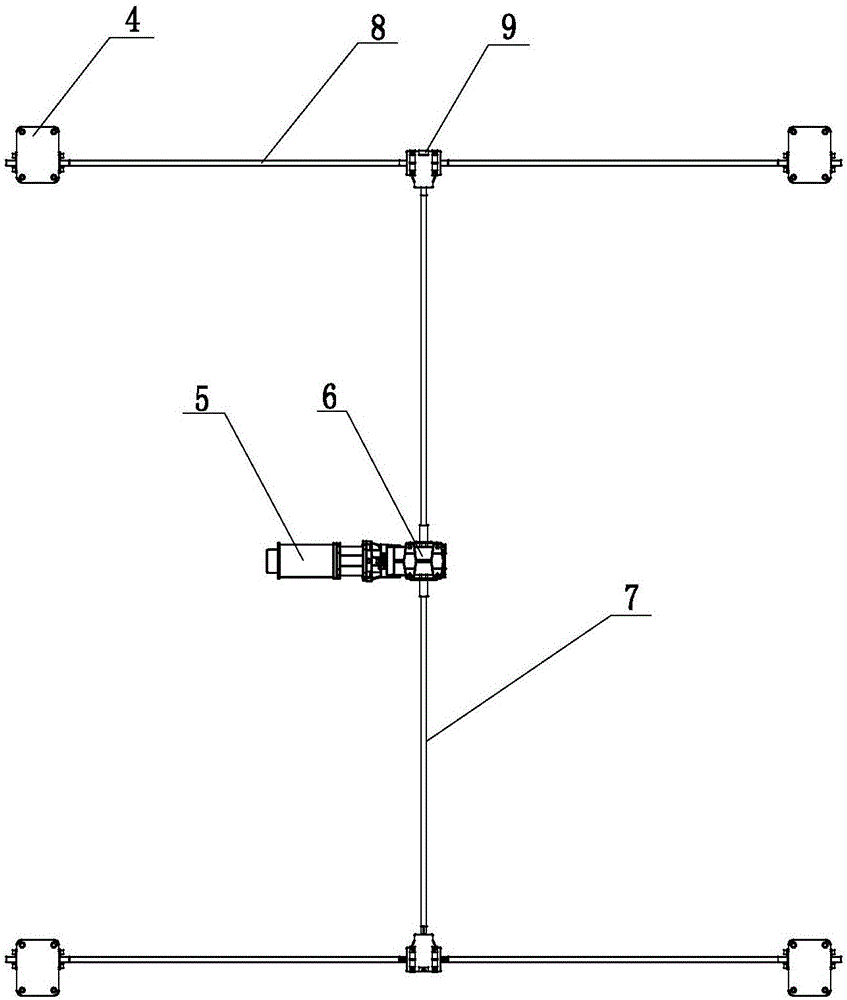

[0015] like Figure 1 ~ Figure 3 As shown, the large aircraft wing assembly working platform of the present invention is composed of three groups of working platforms 1 arranged side by side. The lifting mechanism, each lifting rod 2 is mounted on a base 3, the base 3 is fixedly arranged, and the lifting rod 2 takes the base 3 as a support point to support the lifting of the working table; the lifting mechanism includes a drive motor 5, a reducer 6, a main drive Shaft 7, transmission shaft 8 and four elevators 4 that respectively drive lifting rod 2 to drive up and down, drive motor 5 is arranged at the middle position of the bottom of the worktable, main transmission shaft 7 is connected with drive motor 5 through reducer 6, and main transmission shaft 7. It is arranged horizontally or vertically on the bottom surface of the worktable. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com