A kind of method for preparing phenolic compound

A technology for phenolic compounds and catalysts, which is applied in the field of preparing phenolic compounds, can solve problems such as difficulty and reduce selectivity of phenolic compounds, and achieve the effects of simple preparation, high efficiency and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

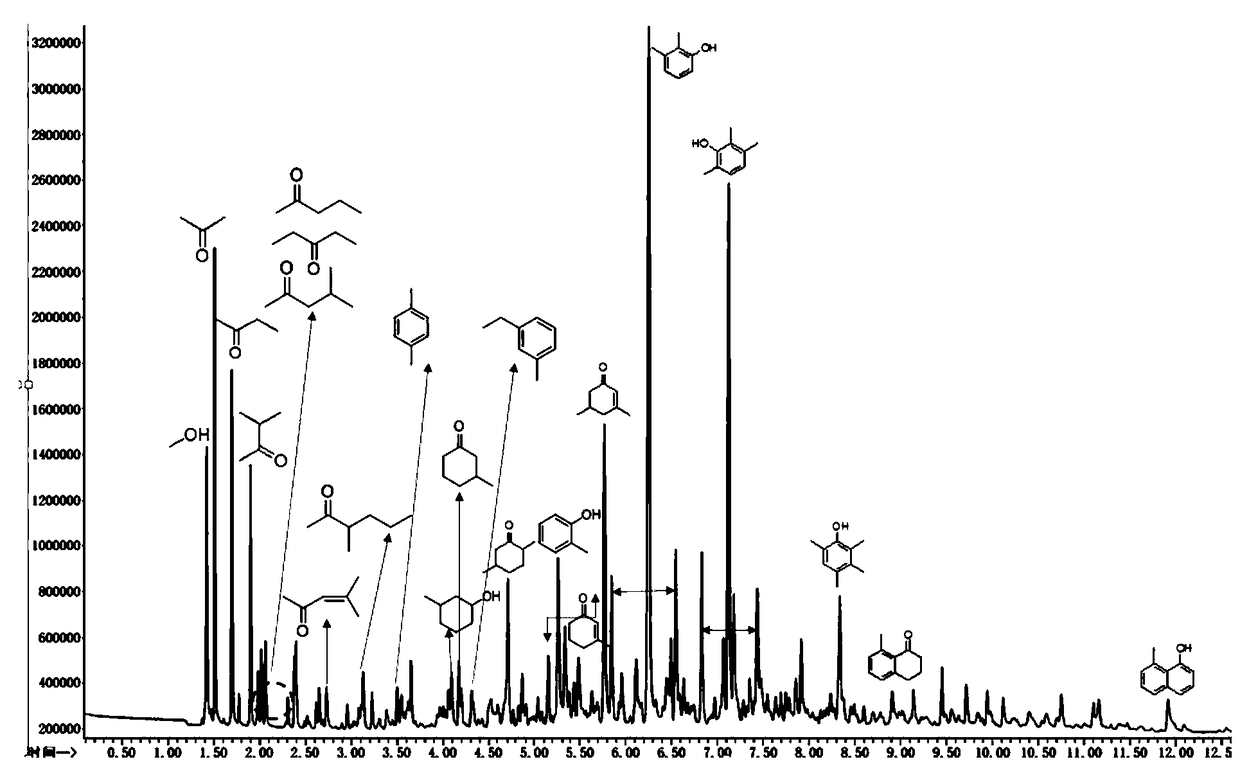

Image

Examples

Embodiment 1

[0027] Weigh 200g of ammonium cerium nitrate and bake it at 500°C for 5h under air atmosphere to obtain cerium dioxide. Fill the 14-25 mesh catalyst with cerium oxide forming sieve into a reaction tube with an inner diameter of 7mm, fill it with a 15cm bed, and under normal pressure, prepare the reaction solution of acetic acid, formaldehyde and ethanol according to the molar ratio of 1:5:1. Raw materials, the feed rate is 0.03mL·min -1 , nitrogen as the carrier gas, the flow rate is 30mL·min -1 , reacted at 350°C for 12h, and separated the liquid after the reaction, and the oil phase and water phase obtained were analyzed by chromatography respectively. The conversion of acetic acid was 70% and the overall selectivity to phenolic compounds was 75%.

Embodiment 2

[0029] Weigh 200g of ammonium cerium nitrate and bake it at 500°C for 5h under air atmosphere to obtain cerium dioxide. Fill the 14-25 mesh catalyst of ceria forming sieve into a reaction tube with an inner diameter of 8 mm, fill it with a 25 cm bed, and under normal pressure, use the reaction solution prepared by acetic acid and formaldehyde according to the molar ratio of 1:5 as the raw material, and feed The speed is 0.03mL·min -1 , nitrogen as the carrier gas, the flow rate is 30mL·min -1 , reacted at 350°C for 12h, and separated the liquid after the reaction, and the oil phase and water phase obtained were analyzed by chromatography respectively. The conversion of acetic acid was 80%, and the overall selectivity to phenolic compounds was 73%.

Embodiment 3

[0031] Weigh 50g of cerium nitrate and dissolve it in 4L of water, use 25wt% ammonia water as a precipitating agent, adjust the pH of the system to 9, centrifuge the obtained precipitate, dry it, and roast it at 500°C for 3 hours to obtain cerium oxide. Fill the 14-25 mesh catalyst with cerium oxide forming sieve into a reaction tube with an inner diameter of 7 mm, fill it with a 9 cm bed, and under normal pressure, prepare the reaction solution of acetic acid, formaldehyde and methanol according to the molar ratio of 1:5:1. Raw materials, the feed rate is 0.03mL·min -1 , nitrogen as the carrier gas, the flow rate is 30mL·min -1 , reacted at 350°C for 12h, and separated the liquid after the reaction, and the oil phase and water phase obtained were analyzed by chromatography respectively. The conversion of acetic acid was 100%, and the overall selectivity to phenolic compounds was 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com