A well killing fluid, a preparing method thereof and applications of the well killing fluid

A technology of killing fluid and action, applied in the field of killing fluid and its preparation, can solve the problems of adsorption and retention damage, difficulty in ensuring reservoir protection effect, etc., and achieve good pumpability, reduce adsorption and retention damage, and facilitate flowback. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

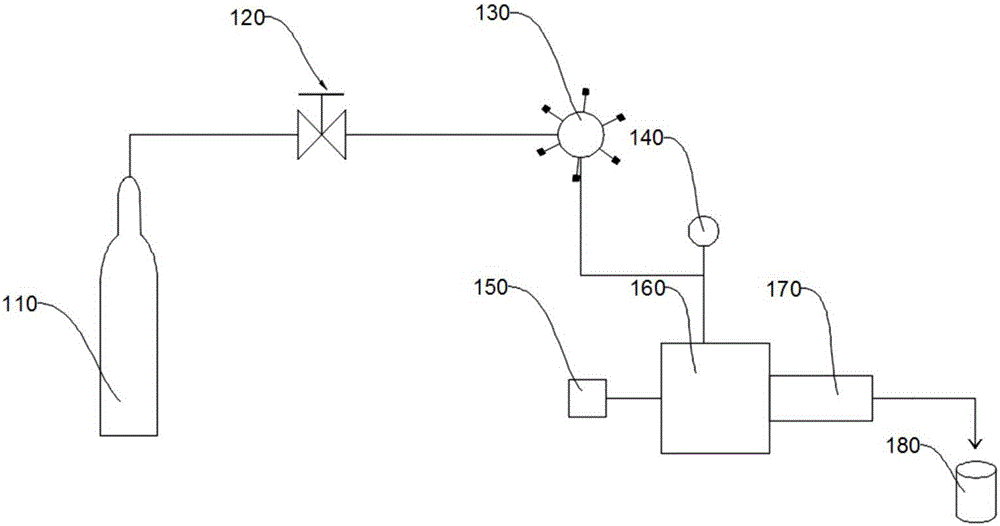

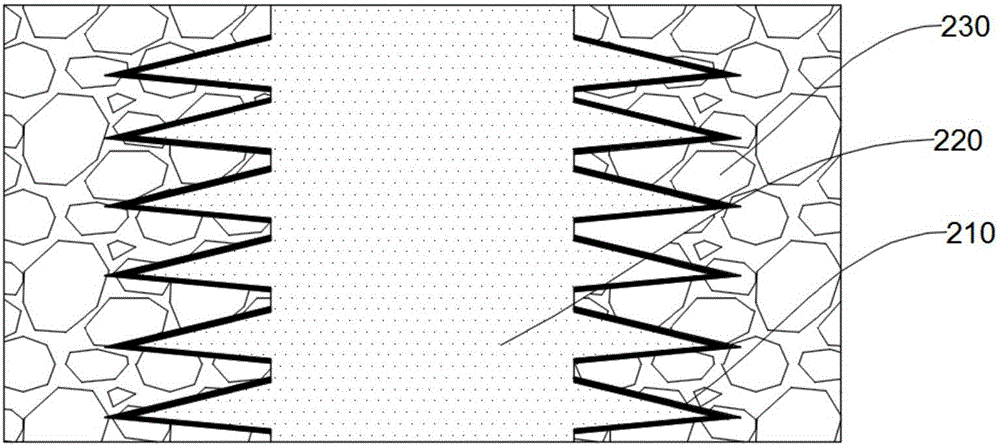

Method used

Image

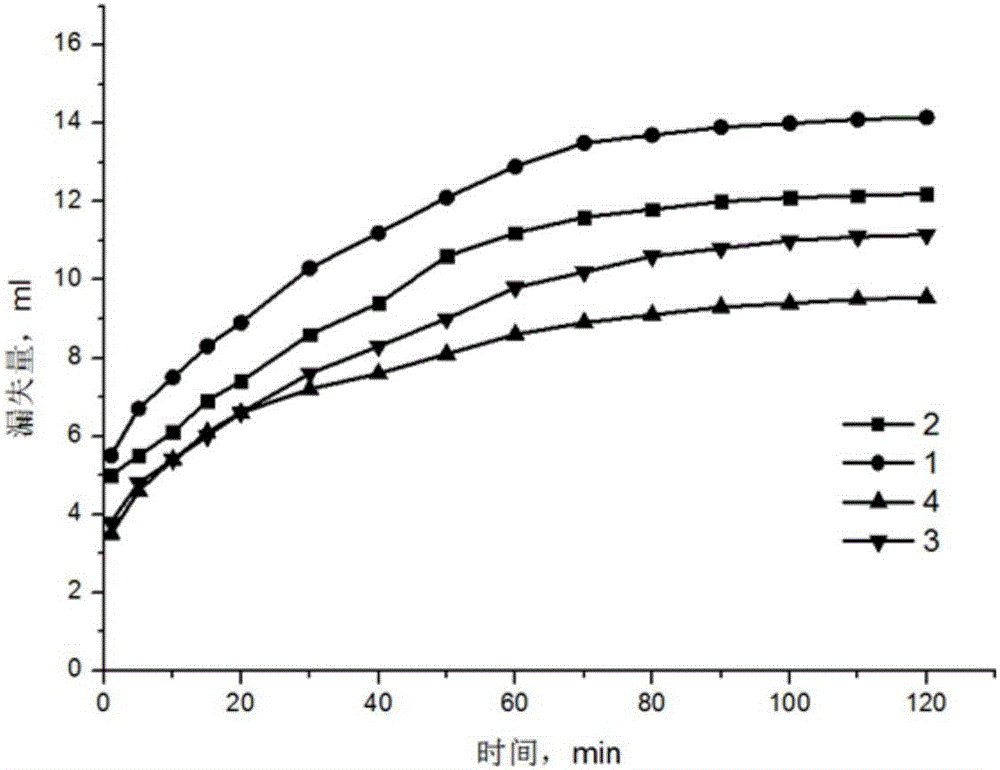

Examples

preparation example Construction

[0034] The present invention also provides the preparation method of the above-mentioned kill fluid, comprising the following steps: adding the second crosslinking agent, the third crosslinking agent, homogeneous, and the first crosslinking agent to the aqueous solution in which the stabilizer and the polymer are dissolved, generating The cross-linking reaction forms a fluid gel.

[0035] Further, in a preferred embodiment of the present invention, dissolving the stabilizer and the polymer in the aqueous solution refers to dissolving the stabilizer and the polymer in water at room temperature and mixing them uniformly.

[0036] In a preferred embodiment of the present invention, in the step of forming a fluid gel through the cross-linking reaction, the time for the cross-linking reaction is 1-3 hours. Preferably, the gel strength of the flowable gel reaches grade C to ensure its pumpability.

[0037]In a preferred embodiment of the present invention, after the cross-linking r...

Embodiment 1

[0041] In the well killing fluid provided in this embodiment, the raw materials of the well killing fluid include 2% polymer, 0.05% of the first crosslinking agent, 1% of the second crosslinking agent, and 0.1% of the third crosslinking agent in terms of mass percentage , 0.02% stabilizer and the balance of water.

[0042] Wherein the polymer is partially hydrolyzed polyacrylamide; the first crosslinking agent is aluminum citrate; the second crosslinking agent is a mixture of hexamethylenetetramine and formaldehyde; the third crosslinking agent is divinylbenzene; the stabilizer It is a mixture of EDTA and thiourea.

[0043] The preparation method of the above well killing fluid.

[0044] First, prepare materials according to the proportion of killing fluid raw materials. Slowly add stabilizer and polymer to the water and stir well. Then add the second cross-linking agent and the third cross-linking agent, and continue to stir until uniform; add the first cross-linking agent...

Embodiment 2

[0046] In this embodiment, a well killing fluid is provided. In terms of mass percentage, the raw materials of the well killing fluid include 1.5% polymer, 0.05% first crosslinking agent, 1% second crosslinking agent, 0.1% third crosslinking agent agent, 0.02% stabilizer and the balance of water.

[0047] Wherein the polymer is partially hydrolyzed polyacrylamide; the first crosslinking agent is chromium acetate; the second crosslinking agent is a mixture of resorcinol and polyethyleneimine; the third crosslinking agent is divinylbenzene and N, A mixture of N-methylenebisacrylamide; the stabilizer is a mixture of EDTA and thiourea.

[0048] The difference between the preparation method of the killing fluid and the preparation method of the killing fluid in Example 1 is that the reaction time at room temperature after adding the first cross-linking agent is 3 hours, and after the killing fluid of the preliminary gel is obtained, the reaction time at 150 degrees Heating at ambi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com