Alkali recovery method and device in cleaning section of continuous annealing and/or galvanizing unit

A technology of lye recovery device and cleaning section, which is applied in the field of cold-rolled strip technology, can solve the problems affecting the commissioning and use quality of the PALL ceramic membrane degreasing system, affecting the cleaning quality of the strip steel, and the maintenance frequency of the entire line of rollers, etc., to ensure The effects of putting into use and using quality, reducing abnormal consumption, and alleviating maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the method and device for recovering alkali liquor in the cleaning section of the continuous annealing and / or galvanizing line of the present invention will be described in detail in conjunction with exemplary embodiments.

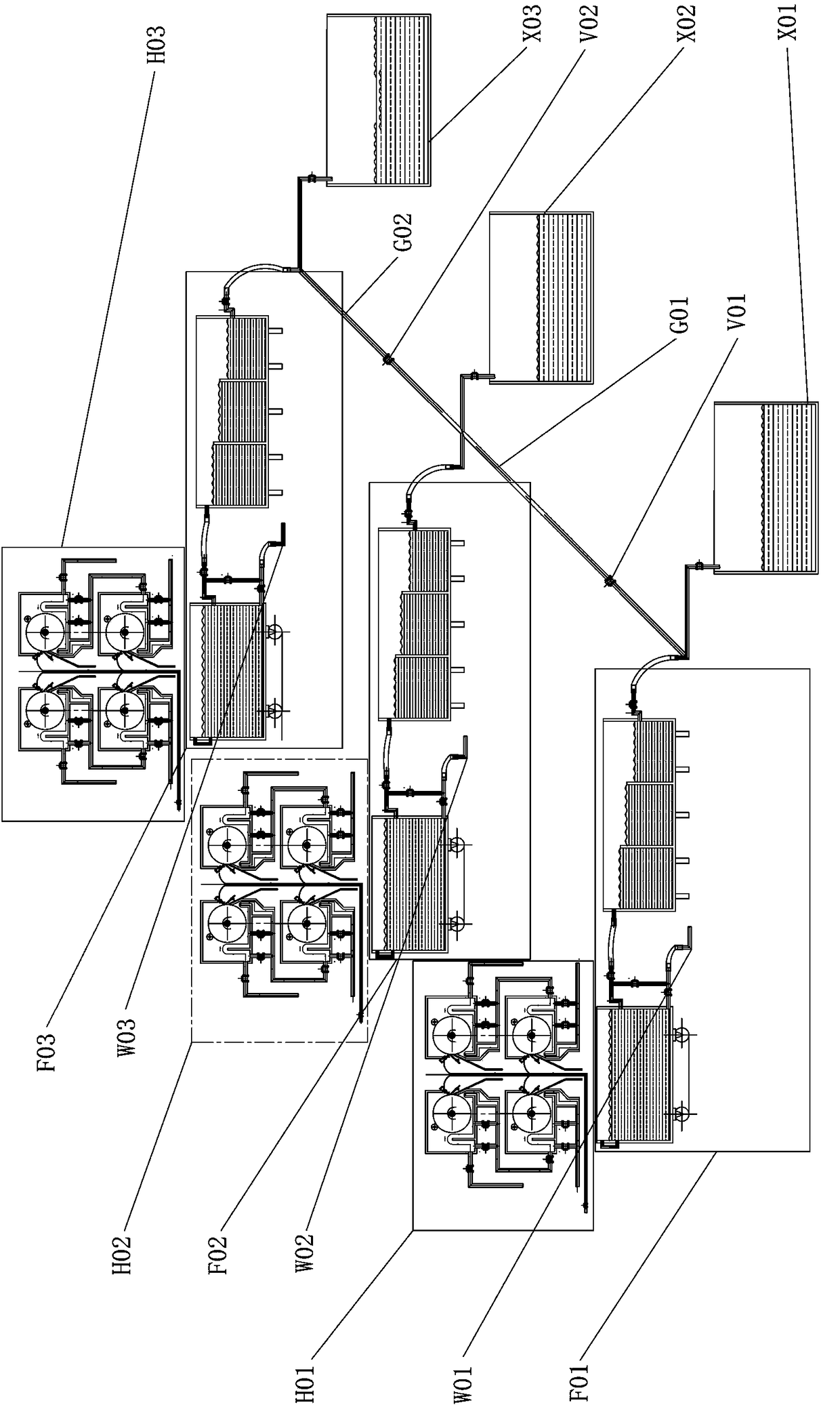

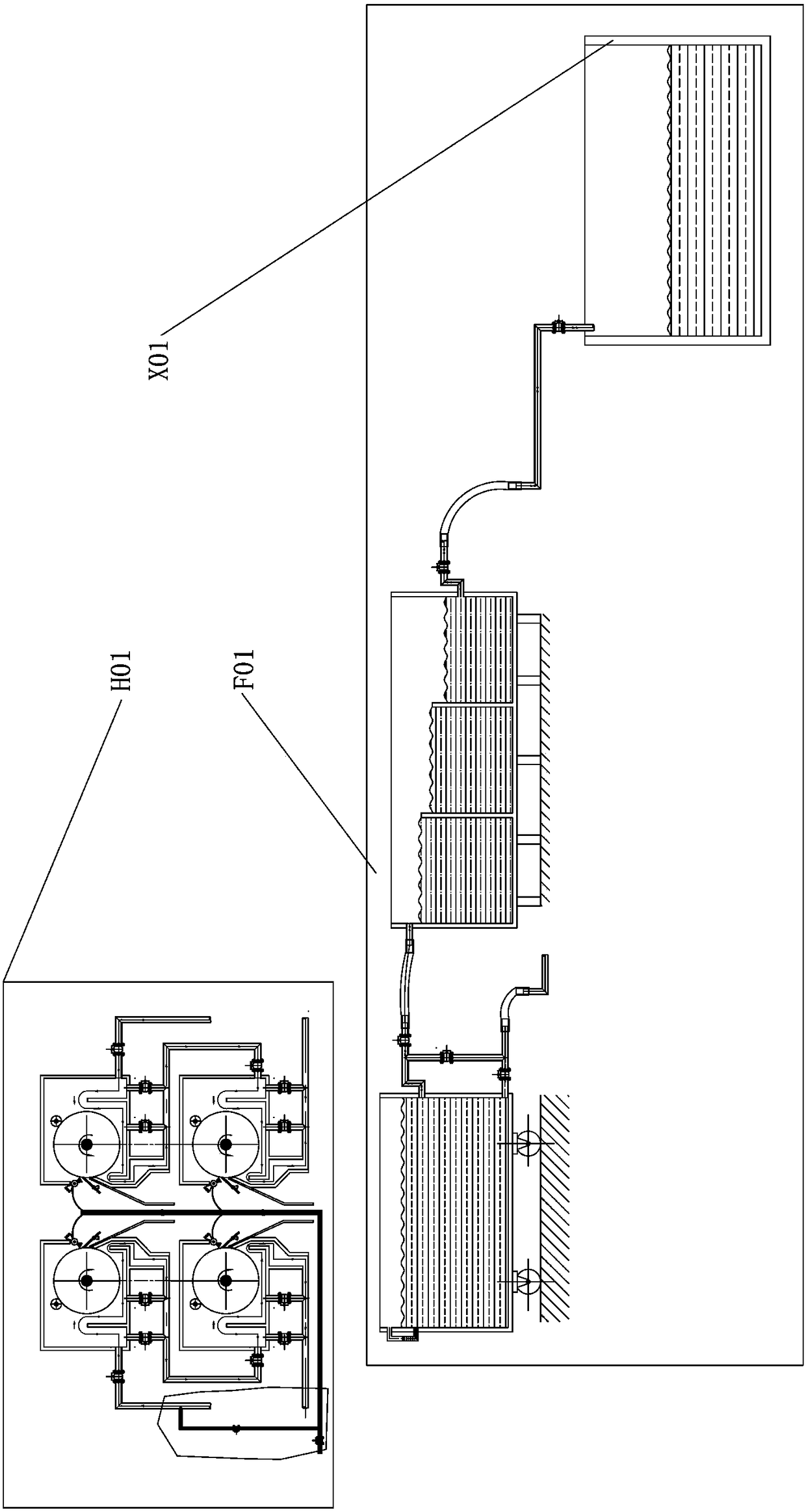

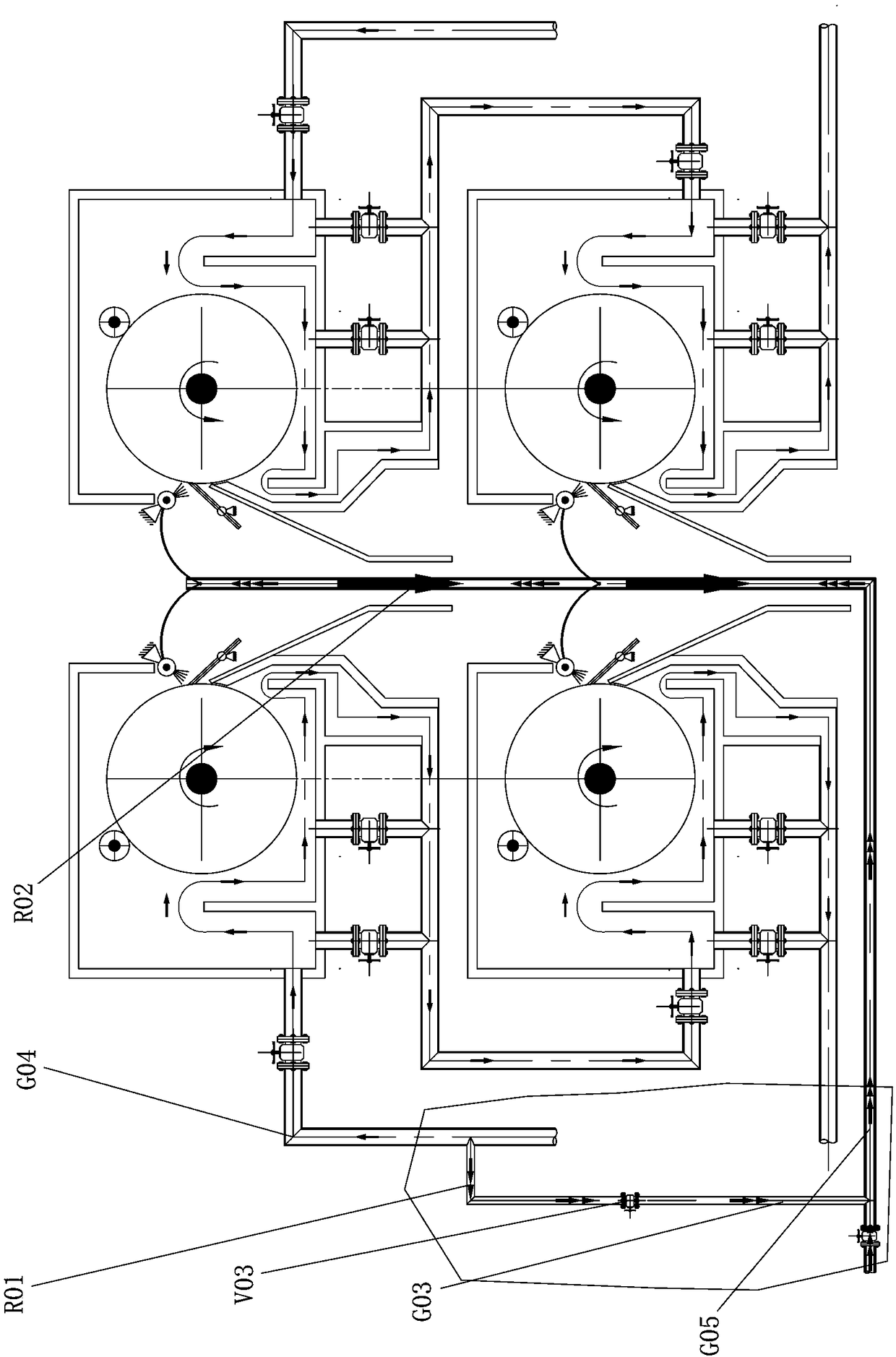

[0020] In an exemplary embodiment of the present invention, the lye recovery device in the cleaning section of the continuous annealing and / or galvanizing line may include a magnetic filter unit, an lye collection unit, an lye settlement purification unit, and an lye storage unit. Preferably, the lye recovery device in the cleaning section of the continuous annealing and / or galvanizing unit can also be composed of two or more sets of aggregates arranged side by side, so as to increase the processing capacity of the lye in the cleaning section. The assembly mentioned here can be made of magnetic filtration unit, lye collection unit, lye sedimentation purification unit and lye storage unit, and in any two adjacent assemblies, the lye stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com