Inlet distortion device of aircraft engine

A technology for aero-engines and air inlets, applied in the field of aero-engines, can solve the problems of poor anti-distortion ability and poor anti-distortion ability of production-quality engines, and achieve the effects of improving test run efficiency, simple disassembly and assembly, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

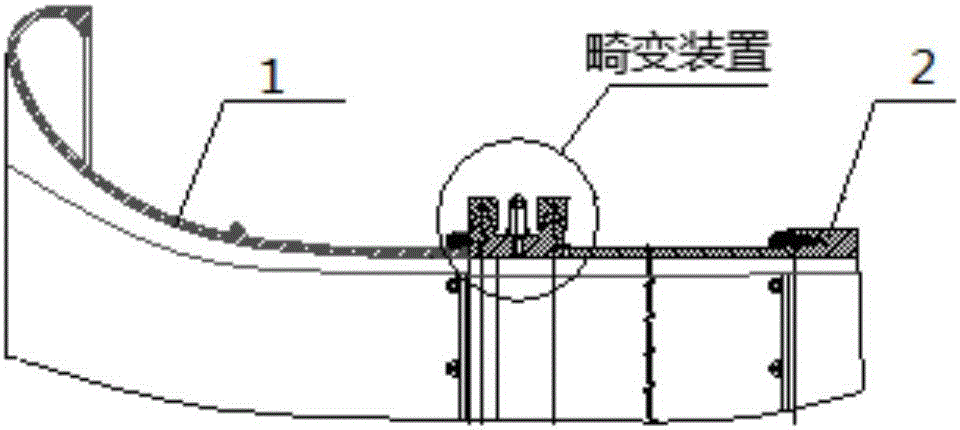

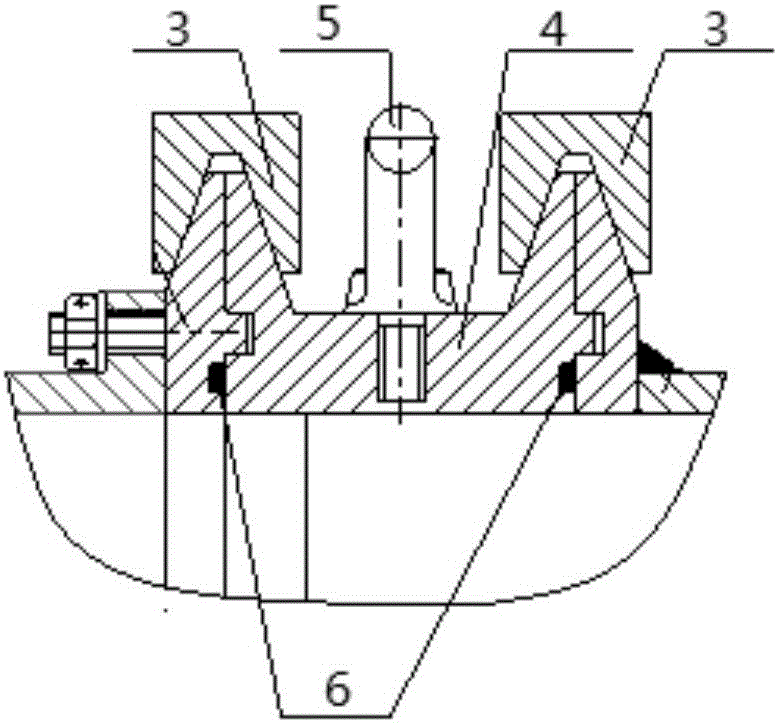

[0018] Such as Figure 1-5 As shown, an air intake distortion device with variable depth for an aero-engine, the distortion device is installed between the air intake 1 and the bell mouth 2 of the engine, and mainly includes two quick-release rings 3, a board seat 4 and a board 5 ;

[0019] One quick-release ring 3 is connected to the bell mouth 2, and the other quick-release ring 3 is fixedly connected to the air inlet 1 through the sealing ring 6. The upper part is a square structure, and the width of the board seat 4 is the same as the diameter of the air inlet. The inside of the board seat 4 is a square board slot, and the board slot is provided with a board sealing block and a positioning card. After the board is inserted, it can Fix the insert plate to fix the insert plate at any position in the insert plate groove, and then realize the shielding of the insert plate at various depths in the air inlet, and generate multiple sets of distortion indices.

[0020] Assuming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum stress | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com